Automation is essential to remain ahead in the fiercely competitive industrial environment of today. The combination of polishing robots and robot tracks is one technological advancement that has greatly increased output. Robot tracks guarantee flawless and reliable polishing results by enabling polishing robots to move effectively and reach various work areas. Let’s examine how this technology may increase production in a variety of sectors and improve the effectiveness of polishing systems.

Robot tracks’ Function in Industrial Automation

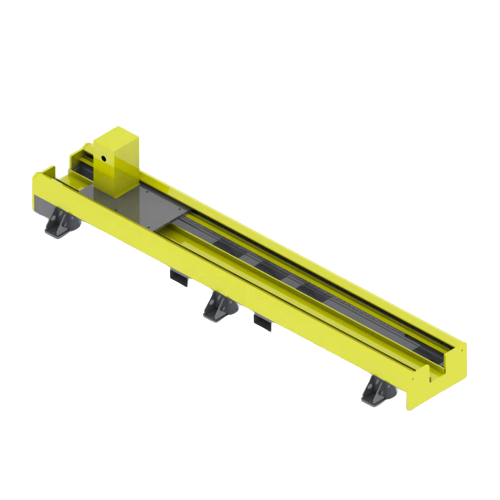

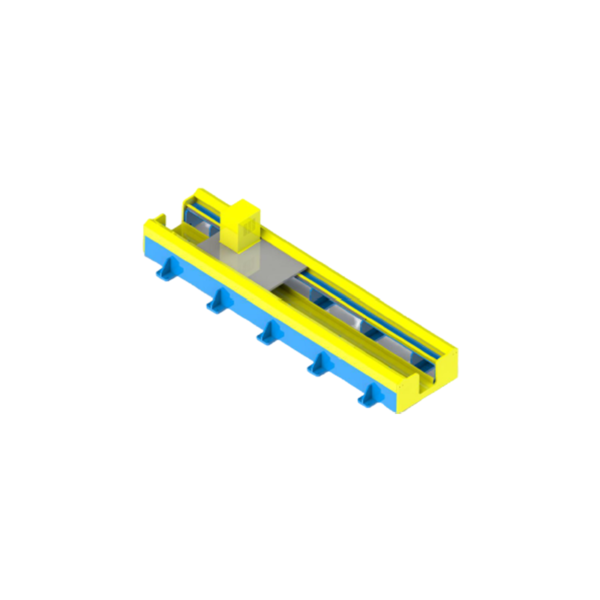

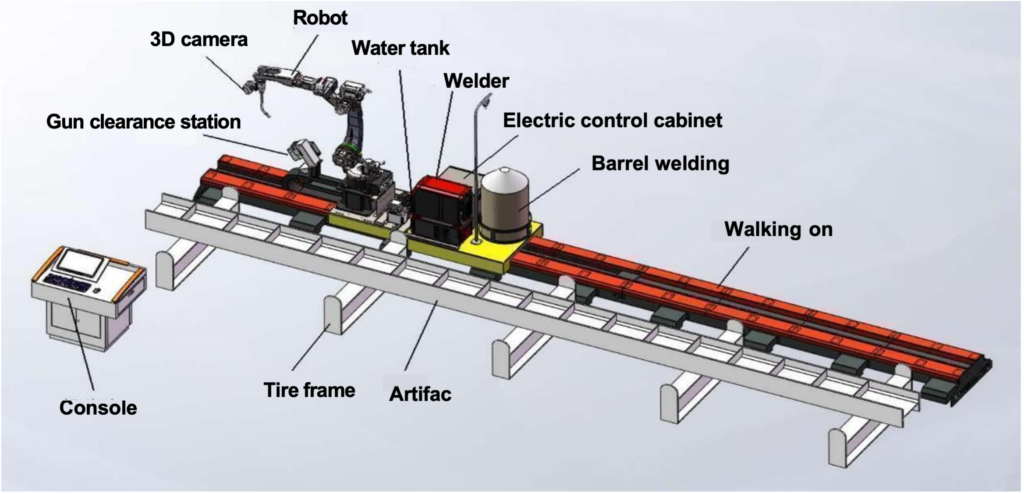

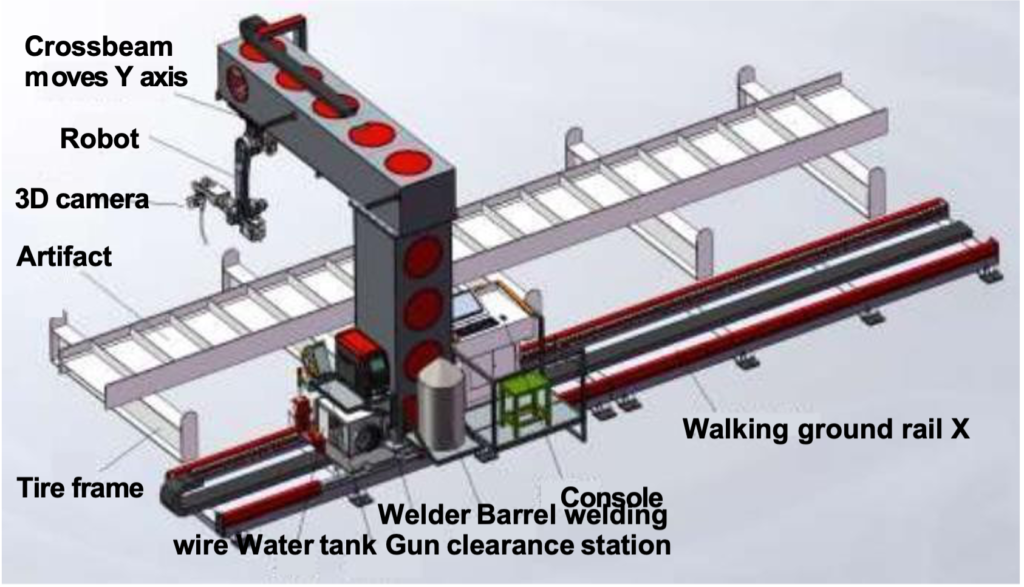

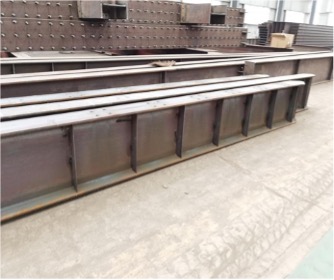

Particularly when used with polishing robots, robot tracks are an essential part of automating production operations. Robots can move smoothly over the manufacturing area thanks to the linear motion platform these tracks provide. Robot tracks enable that polishing robots may operate without human assistance in applications that demand regular surface finishing. In order to manage larger or more complicated workpieces with more accuracy and higher-quality finishes, this constant movement is crucial. Robot tracks maximize space utilization, cut down on manufacturing time, and remove pointless stops by permitting wider reach.

Increasing Adaptability with Robotic Polishing

The goal of polishing robots is to provide a higher surface quality, which is essential for sectors including consumer goods, automotive, and aerospace. By incorporating robot tracks, these robots can cover bigger sections or many workpieces with the flexibility they require. Polishing robots on robot tracks may travel throughout a complete assembly line rather than being limited to a single stationary spot, guaranteeing uniform quality across all items. In addition to guaranteeing increased output, this flexibility helps producers to keep their goods at a constant level of quality.

Enhanced Accuracy and Effectiveness

More accuracy in polishing applications is made possible by the incorporation of robot tracks. The proper pressure and angle for polishing surfaces may be maintained by polishing robots since they can move fluidly between positions, resulting in an equal finish. Errors caused by manual repositioning or inconsistent handling are minimized by the precise mobility offered by robot tracks. Working with high-value components, where any flaw may be expensive, makes this degree of control crucial.

Efficiency in Cost and Long-Term Gains

Long-term cost benefits can be achieved by strategically investing in polishing systems with robot tracks. Lower labor expenses result from the automation of polishing robots, which lessens the need for human work. Additionally, robot tracks‘ accuracy and uniformity lead to fewer mistakes and a notable decrease in waste. Therefore, by maximizing material use and reducing the need for rework, producers may attain a greater return on investment, which eventually results in a more economical production process.

Reduced Manual Intervention and Increased Safety

In every factory setting, safety is a top priority, and robot tracks help to make the workplace safer. Robot tracks decrease the requirement for manual component handling, lowering the danger of workplace accidents by enabling polishing robots to travel autonomously. Human workers are exposed to fewer dangers when repetitive and sometimes dangerous polishing chores are automated, resulting in a safer and more effective working environment. Robot tracks are thus a crucial part of a contemporary automated polishing system that prioritizes worker safety and productivity.

Uses in Various Industries

Many sectors can benefit from the usage of robot tracks with polishing robots. These technologies are utilized in the automobile industry to provide car panels the ideal surface quality, guaranteeing both corrosion protection and visual attractiveness. While robot tracks allow for coverage of broader regions, polishing robots in the aerospace sector precisely clean the surfaces of key components. Even in the consumer goods industry, this technology guarantees that products like as electronic gadgets and kitchen appliances are finished to a high standard and satisfy customers.

In conclusion

A revolutionary way to increase efficiency, flexibility, and quality in polishing applications is to integrate robot tracks with polishing robots. This potent combination guarantees accuracy and consistency in addition to automating repetitive processes, which raises the quality of the final output and reduces expenses. Incorporating robot tracks into polishing processes is a viable approach for industries seeking to increase productivity, lower mistakes, and establish a safer working environment. Manufacturers may maintain a competitive edge and confidently and effectively handle the expanding needs of the modern market by utilizing this cutting-edge automation technology.