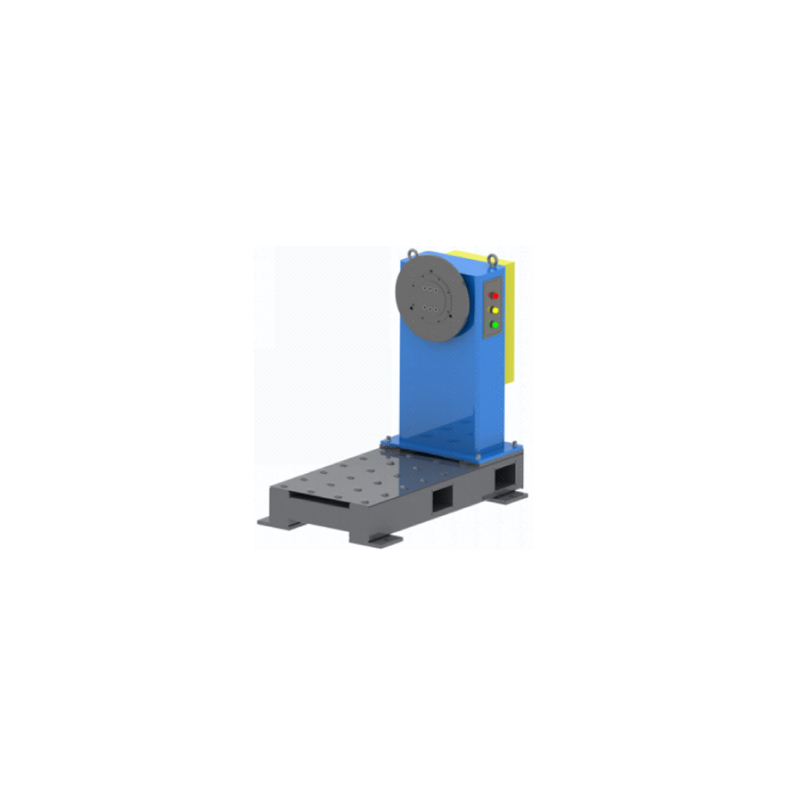

Product Details: L-Type Turntable for Welding

The exceptional characteristics of the EVS DWP-L 500/1000/2000 and other L-Type welding turntables make them ideal for handling large workpieces. This two-axis rotating turntable can hold weights ranging from 500 to 2000 kg. The L-shaped chassis provides a strong, solid foundation, allowing laser welding robots to maintain precision when welding big components. Furthermore, its 0.09 to 0.9 rpm rotation speed ensures controlled, smooth movement during welding. This welding turntable provides the stability needed to create accurate and dependable welds with a repeatability of ±0.1 mm.

Tasks requiring heavy-duty handling and excellent positional precision are ideal for the L-Type welding turntable. The L-Type turntable gives laser welding robots a stable base so they may operate at their best without worrying about moving or misaligning. Industries handling big, heavy materials that need a steady welding environment are a good fit for this type.

Product Details: C-Type Turntable for Welding

The increased adaptability of the C-Type welding turntable, such the EVS DWP-C 200/500/1000, makes it perfect for applications requiring flexibility. With a two-axis rotation that enables tilting and turning, this model has a weight capacity of up to 1000 kg. Laser welding robots can access numerous welding angles because to the C-shaped frame design, which makes it possible to weld complicated designs. With a rotating speed range of 0.1 to 1 rpm, laser welding robots can maintain steady welding rates for a variety of activities.

For managing complex welds and reaching difficult angles, the C-Type welding turntable‘s exceptional movement flexibility is essential. Because it can tilt and rotate at the same time, laser welding robots can move between parts of the workpiece without pausing. Small to medium-sized items that need accurate, multi-angle welding skills are best suited for this type. Each weld is highly accurate due to the repeatability of ±0.1 mm.

L-Type and C-Type Welding turntables: Stability vs. Flexibility

Stability versus flexibility is the primary distinction between welding turntables of the L-Type and C-Type types. When working on large and heavy components, laser welding robots may operate steadily on L-type welding turntables. The sturdy design guarantees consistent precision welding of even the heaviest workpieces. By reducing movement and vibration, the L-Type design guarantees that laser welding robots consistently produce high-quality welds.

Laser Welding Operations and the Function of Welding turntables

The performance of laser welding robots is improved by both L-Type and C-Type welding turntables. Robots can maintain a regular welding path and achieve uniform weld quality by using these turntables, which offer controlled tilting and rotational movement. For instance, the stability of the L-Type turntable is crucial in heavy-duty applications because it keeps the workpiece safe and allows laser welding robots to weld continuously. By reducing human mistake, this automation enhances overall weld quality in addition to saving time.

What Kind of Welding turntable Is Best for You?

Your welding operation’s particular needs will determine whether you should choose an L-Type or C-Type welding turntable. The ideal choice is the L-Type turntable if stability and the capacity to manage big workpieces are crucial. Laser welding robots can effectively operate on massive components because to their strong frame and high load capacity. On the other side, the C-Type welding turntable is perfect if you need flexibility and access from several angles. Because of its flexible architecture, laser welding robots can easily execute intricate welds.

The materials and kinds of welding operations you are working with will eventually determine your choice. The L-Type welding turntable will give enterprises working on large-scale projects the strength and stability they require. The C-Type welding turntable will be useful for businesses that need accuracy and adaptability.