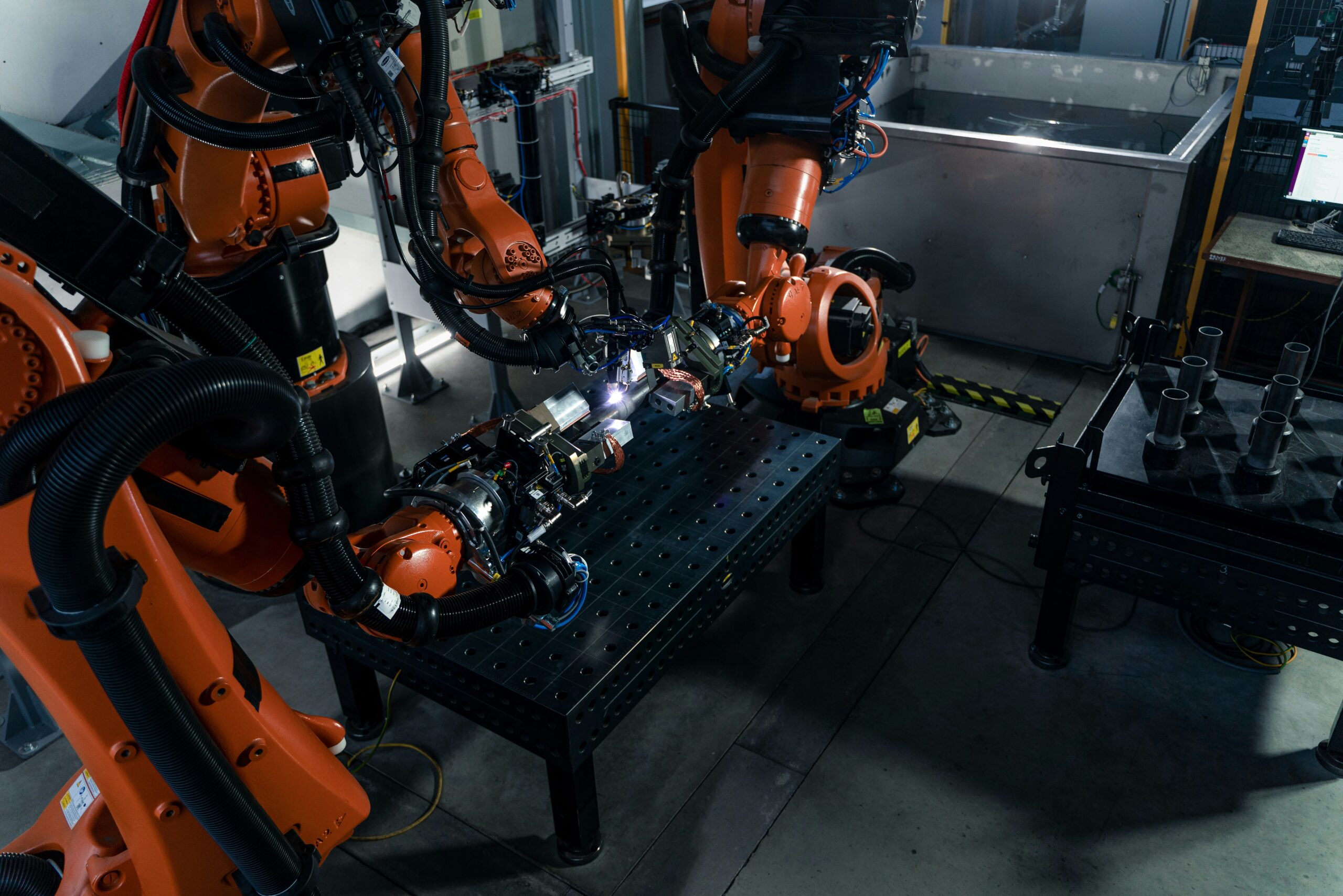

Productivity advances with the accompaniment of precision and efficiency in the complex ballet of manufacturing. Within this symphony of production, welding turntables and laser welding robots have emerged as pivotal components that have significantly transformed the welding procedure. As demonstrated by the “6KG Payload 2014mm Reaching Distance 6 Axis Welding Robot QJR6-2000H” and the “Single Axis Welding Positioner EVS-SWP-ZW-500/800/1200,” these technologies function as collaborators rather than mere instruments, collaborating harmoniously to accomplish feats that were previously deemed unachievable. The integration of these components signifies a significant advancement in manufacturing capacities, providing welding quality and productivity with unprecedented levels of precision, adaptability, and effectiveness.

Developments in Robotic Laser Welding

Laser welding machines have become an integral component of contemporary manufacturing, revolutionizing the welding procedure with their exceptional accuracy and velocity. The sophisticated functionalities of these robots are fundamentally altering the industrial production domain by presenting remedies that augment both quality and efficiency.

The QJR6-2000H: A Precision Paradigm

One of the leading products of this technological revolution is the “6KG Payload 2014mm Reaching Distance 6 Axis Welding Robot QJR6-2000H.” Featuring a design optimized for welding with gear gap adjustment, a hollow structure with a wrist U-shaped design for enhanced joint support rigidity, and a noise reduction patent, this robot exemplifies engineering excellence. Antishake optimization and endclearance reduction serve to augment the operational stability and control accuracy of the device, thereby solidifying its status as an indispensable instrument for precision welding.

The QJR6-2000H is equipped with an armspan of 2014mm and a repeat positioning accuracy of ±0.08mm. This grants it unparalleled precision and adaptability in manipulating a diverse range of materials, such as carbon steel, stainless steel, aluminum, and copper. In addition to facilitating access to difficult-to-reach welding sites, its six-axis design enables complex motions, demonstrating its adaptability and effectiveness in a wide range of welding applications.

The Advantages of Laser Weld Robots

There are several benefits associated with the incorporation of laser welding robots, such as the QJR6-2000H, into manufacturing processes. Their capability of producing consistent, precise welds at high rates enhances operational efficiency and product quality substantially. Furthermore, their adaptability in managing diverse materials and intricate welding operations creates novel opportunities for advancements in product design and production.

Increasing Accuracy by Utilizing Welding Turntables

In contrast to the precision and adaptability that laser welding robots impart to the welding procedure, welding turntables furnish the essential stability and placement required to attain ideal outcomes. These devices are critical in guaranteeing the utmost precision and effectiveness in the execution of each weld.

The EVS-SWP-ZW Series: Precision Support

In contemporary manufacturing, welding turntables are indispensable, as demonstrated by the “Single Axis Welding Positioner EVS-SWP-ZW-500/800/1200.” This series of gyroscopes is engineered to handle burdens spanning from 500kg to 1200kg. With a rated gyration speed of 70°/S and repetition positioning accuracy ranging from ±0.10mm to ±0.15mm, it guarantees accurate and adaptable workpiece positioning throughout the welding procedure.

The EVS-SWP-ZW series is constructed using premium materials and is outfitted with an RV precise reducer and AC servo motor. Substantially enhancing the quality and efficacy of the welding procedure, this amalgamation guarantees exceptional gyration stability and positioning precision. It provides a versatile platform suitable for an extensive range of welding applications, in addition to ensuring durability through its sophisticated design and robust construction.

In Conjunction with Laser Welding Robots

In order to facilitate intricate welding operations, welding platforms such as the EVS-SWP-ZW series supplement laser welding robots by offering the required mobility and adaptability in position. The exceptional weld outcomes achieved through the combination of the turntable’s adaptability and the robot’s accuracy showcase the efficacy of incorporating cutting-edge technologies into the manufacturing process.

The Merger of Welding Turntables and Laser Welding Robots

By coordinating welding turntables (EVS-SWP-ZW series) with laser welding robots (QJR6-2000H), a unified system is established that enhances the precision, speed, and quality of welding procedures. The aim of this synergy extends beyond the simple integration of two technologies and encompasses the creation of a cohesive system whose functionalities exceed those of its individual components.

Attaining Outstanding Welding Outcomes

By precisely matching welding turntables with laser welding robots, manufacturers are able to attain superior welding outcomes. The machines utilize their unparalleled precision and adaptability to execute intricate welds with exceptional consistency. In contrast, the turntables provide the capability to precisely position and rotate workpieces. This amalgamation guarantees flawless execution of each weld, irrespective of the intricacy of the undertaking.

Practical Implementations

The pragmatic implementation of these technologies is evident across diverse sectors characterized by an absolute need for accuracy and productivity. An exemplary sector to consider is the automotive industry, where welding precision and strength are indispensable for the long-term safety and integrity of vehicles.

Motorcycle Production Line Case Study

The integration of QJRH4-1A welding robots and QJRB20-1 handling robots in a project comprising 21 units of each robot revolutionized the motorcycle manufacturing process. Three motorcycle welding lines could now be automated thanks to laser welding robots and welding turntables, which substantially increased output and decreased labor expenses. This case study exemplifies the profound effects that can be achieved by integrating welding turntables and laser welding robots, with regards to both product quality and manufacturing efficiency.

Conquering Obstacles in Robotic Welding

Although the amalgamation of welding turntables and laser welding robots presents a multitude of advantages, it also engenders a number of obstacles. These include the integration of these systems into existing manufacturing processes, the requirement for specialized training for operators, and the substantial initial investment in technology.

Confronting Operational and Technical Obstacles

By adopting a phased approach to technology integration, investing in workforce training and development, and selecting equipment that is compatible with current operations, manufacturers can surmount these obstacles. Systems such as the QJR6-2000H and EVS-SWP-ZW series are well-suited for a diverse array of applications due to their adaptability and capacity for expansion, which enables them to be progressively integrated into manufacturing processes.

Advancements in Robotic Welding in the Near Future

Consensus on the future of robotic welding is bolstered by the fact that continuous technological advancements are positioned to augment the capabilities of welding systems. As a consequence of progressions in artificial intelligence (AI) and machine learning, it is anticipated that welding robots will acquire enhanced intelligence and autonomy, enabling them to dynamically adapt to conditions and optimize processes seamlessly.

How to Acquire a Competitive Advantage by Embracing Innovation

Manufacturing organizations that adopt a proactive approach towards technological innovation will achieve a competitive edge. By adopting cutting-edge welding solutions that improve accuracy, productivity, and efficiency, organizations can attain unparalleled levels of success in the manufacturing sector.

Conclusion

By combining laser welding robots and welding turntables with unmatched precision, efficiency, and quality, this innovation signifies a substantial progression in manufacturing technology. The capabilities of these technologies to work in tandem, as exemplified by practical implementations such as the motorcycle assembly line, can revolutionize manufacturing procedures, resulting in exceptional product excellence and substantial financial savings. Notwithstanding the obstacles, the prospects offered by these advancements are immense, and the trajectory of robotic welding points toward further triumphs. Through the utilization of welding turntables and laser welding robots, producers can anticipate a future in which the limits of accuracy and productivity are perpetually pushed to the limits.