Building an industrial robot, like an EVS robot arm, is not an easy fit, considering the type of work they handle on a daily basis. They have to be strong, solid, and reliable if they are to be used for a long time. The materials used to make them vary from some of the most common metallic elements to the hardest ones around.

We are going to explore the type of materials that are used in the construction of an industrial robot, how they affect their functionality, and the benefits they bring to the table. If you have always been curious to know what goes on behind the scenes, then this is for you.

Steel

Source: Pinterest

Steel is one of the hardest and most durable materials around and it is only normal that robot manufacturers would consider using it in making the outer skeletons of industrial robots. It is a very sturdy metal that is widely available and easy to forge into any shape one may want. Steel gives the robot the ability to withstand high temperatures and other harsh conditions that would destroy any normal material.

Steel comes in many versions, each designed for specific roles. It can be converted into a steel carbon alloy by the addition of carbon, and this further strengthens it. There are other types of steel like ultra-wear resistant steel that can withstand all kinds of heavy impacts and would work well in robots that deal with punching and drilling in the automotive industry.

Benefits of robots made with steel include a high tolerance for heat which means all the delicate parts are well insulated from damage no matter how hot things may get on the outside.

Aluminum

Source: Pinterest

Aluminum is another common metal that is easy and cheap to create. Although not as hard as steel, it has the advantage of being very strong without having to be very heavy. This makes it the ideal material to construct nimble industrial robots like SCARA robots that rely on speed. Robots made with aluminum are able to move from one place to another very quickly without compromising their own structural integrity.

Aluminum also has a better luster than other metals. They add a shine to the robots allowing room for many aesthetically pleasing modifications, which isn’t a bad thing even though they don’t affect the functionality. Aluminum is sometimes used alongside steel to protect the delicate parts of the robot as it has a very high-temperature tolerance.

Rubber

Source: Pinterest

The disadvantage of using metals for all the parts of an industrial robot is that they will lack the ability to handle tasks quickly. To counter this, rubber is added to the mix and is mostly used for holding together joints and other moveable parts for flexibility.

Rubber also serves the function of giving the industrial robot some texture, especially where robotic arms are involved. This makes them more appealing and less scary to look at, making them easy for humans to work alongside them.

The only drawback to having rubber is that it is vulnerable to heat, and unless it is covered with a protective layer, it can be used for tasks like welding. However, they are good to go for other robots like pick and place, among others.

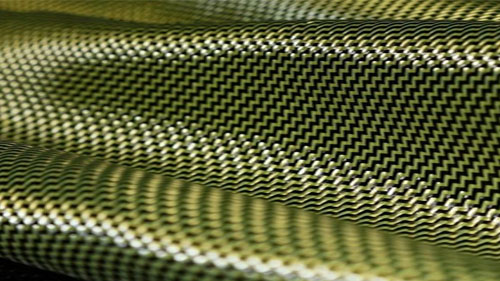

Kevlar

Source: Pinterest

This is a synthetic fiber commonly used for bullet proof vests and that should tell you all you need to know about their capabilities. Kevlar can be a good protective layer for industrial robots that deal with extreme conditions like heat, extreme cold, and pressure as they are able to repulse any damage for a very long time. And that’s why they are very expensive.

The other advantage of Kevlar is the fact that it can be designed in any style and shape to fit even the smallest of crevices that may be exposed to the elements. They are also very flexible, you could cover the entire surface of a robotic arm, and it would still retain all the necessary movements needed for operations without affecting the speed.

In terms of aesthetics, Kevlar comes in different textures and colors, and it can be modified into customized patterns and even engraved with logos and emblems. Therefore, on top of protecting the robots, kevlar adds some beauty into the picture.

Bioplastics

Source: Pinterest

We are moving towards a sustainable form of manufacturing, and using non-degradable materials is being discouraged and cut by major manufacturers around the globe. But for the goal of green earth to be achieved, there have to be alternatives, and this comes in the form of bioplastics.

Although development and research are still ongoing for them at the moment, what has been seen so far indicates that bioplastic material has the potential to be used to make important parts of the robot—especially the delicate parts in movable joints that have to be strong and flexible at the same time.

More money is being pumped into their development at the moment, and it is only a matter of time before the entire manufacturing community embraces this new material for all their robotic applications. The only drawback is its inability to tolerate heat, and for this reason, bioplastics cannot be used for high-intensity robots like welding robots. But they sure can come in handy for smaller robots designed for fast and simple tasks.

Conclusion

There are countless other materials that are used to make industrial robots. When choosing the materials to go with, robot makers have to consider the budget, availability of the material, durability, and tolerance. All this comes into play in the many types of manufacturing robots, allowing for the injection of only the best qualities into the final product.