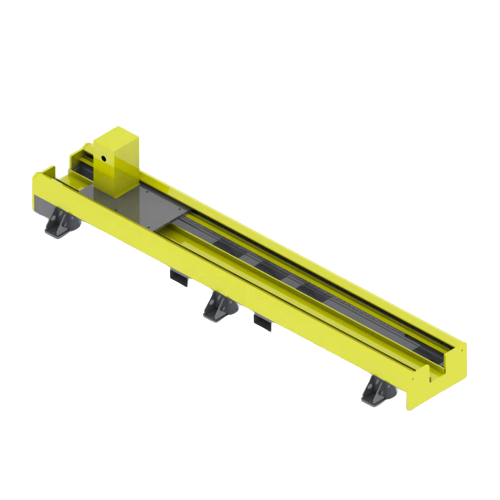

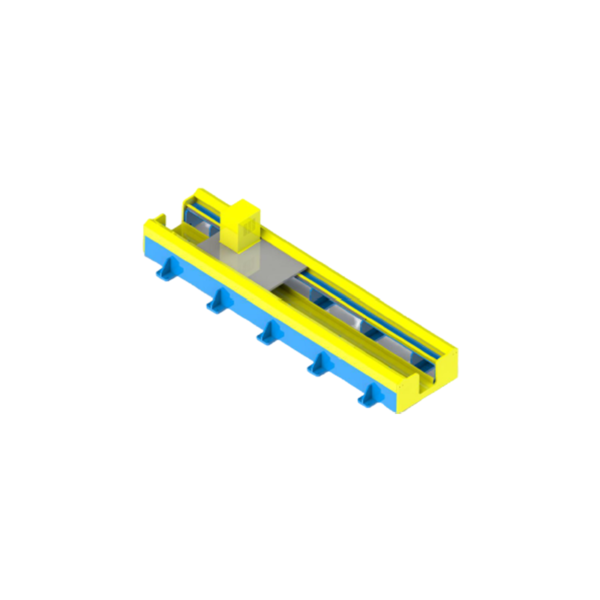

Robot tracks are crucial for enhancing smart logistics systems in the age of industrial automation. The mobility and effectiveness of robotic systems in manufacturing facilities, warehouses, and other sectors are greatly increased by these tracks. By expanding the reach of industrial robots and enabling them to move easily over expansive areas, EVS’s robot tracks, such as the Robot Walking Rail, provide a potent answer. This essay will examine how increased flexibility, productivity, and overall operational efficiency are all benefits of smart logistics when using robot tracks.

Robot tracks: Improving Mobility

In smart logistics, where processes depend on the effective movement of robots, mobility is essential. Robotic devices can travel longer distances with ease thanks to robot tracks. Because of its short range, a robot in a typical arrangement is usually confined to a small area. Businesses may greatly boost their robots’ mobility by including robot tracks like the EVS Robot Walking Rail. This improvement is particularly helpful in large-scale logistics operations when it’s critical to arrive to various zones promptly and effectively.

Robot tracks allow for smooth movement within a building, which lowers costs and boosts productivity. Robot tracks are an essential part of smart logistics because they allow the robots to travel consistently and smoothly along these tracks, allowing them to do their jobs without needless delays.

Increasing Efficiency in Intelligent Transport

Operational efficiency is increased significantly when robot tracks are integrated into smart logistics systems. These tracks assist decrease downtime and boost production by enabling robots to roam across wider regions without the need for human involvement. Robot tracks make sure that resources and items are moved swiftly from one area to another in logistics facilities where speed is of the essence, simplifying the whole process.

Furthermore, the automation made possible by robot tracks reduces human error—a frequent problem in manual handling. This lowers the possibility of product damage while also increasing process precision. Because of its ability to support huge loads and extended distances, the EVS Robot Walking Rail guarantees that robots can carry out a variety of duties in expansive areas, therefore increasing the efficiency of smart logistics.

Robot tracks’ Adaptability and Flexibility

The versatility of robot tracks is one of their biggest benefits. Robots must be able to adapt to a variety of jobs in order for smart logistics systems to work, from assembly-line duties to cargo transportation. The EVS Robot Walking Rail offers unmatched versatility in production and logistics settings and can be tailored to meet various operating requirements.

Robot tracks can adapt to various operational procedures thanks to their variable speeds and movement patterns. This flexibility is essential for sectors where daily logistical demands might change. A seamless operation is guaranteed regardless of the duties at hand with smart logistics systems that contain robot tracks, which can readily adapt to changing requirements.

Cuts to Operational Expenses

The decrease in operating expenses is an additional advantage of utilizing robot tracks in smart logistics. Robot tracks lessen the need for more robots to cover the same area by increasing the range and capabilities of a single robot. This implies that businesses might reduce their initial investment expenses by using fewer devices to attain better efficiency.

By avoiding wear and tear on the robots themselves, robot tracks also save maintenance expenses. The rails provide a directed and smooth course, minimizing the likelihood of obstructions or interruptions that might result in harm to the robots. Robots running on robot tracks are a key asset in smart logistics systems because of their longer lifespan, which results in long-term cost savings.

Increasing Dependability and Safety

Robot tracks help to create a safer workplace since safety is a primary focus in smart logistics. Robot tracks prevent robots from running into people or other machinery since they have perfect control over their movement. Because fewer people must manually operate along the rails, there is a lower chance of mishaps and injuries.

Another important benefit of robot tracks, such as the EVS Robot Walking Rail, is their dependability. These systems are designed to withstand high loads and extended operating hours, guaranteeing uninterrupted logistical operations free from unforeseen downtime. Robot tracks are a trustworthy part of smart logistics because of their sturdy design, which keeps robots operating in hectic situations.

Robot tracks: The Future of Smart logistics

The function of robot tracks will grow increasingly more important as smart logistics advances. Robot tracks are at the forefront of this revolution as the demand for automation and effective material handling rises across all sectors. Future robot tracks will probably have even more advanced features, such improved tracking, self-learning capabilities, and real-time environment modifications, thanks to improvements in robotics and artificial intelligence.

One great illustration of how robot tracks may optimize effectiveness in smart logistics is the Robot Walking Rail from EVS. Because of its capacity to increase operational flexibility, save costs, and expand the range of robots, it is a vital tool for businesses trying to remain competitive in the contemporary industrial scene.

In summary

To sum up, robot tracks are an essential part of smart logistics, improving industrial settings’ mobility, efficiency, and safety. Businesses may optimize their robotic systems and ensure speedier, more dependable, and more seamless operations by integrating robot tracks like the EVS Robot Walking Rail. The significance of robot tracks in smart logistics will only increase as sectors continue to embrace automation, opening the door for more creative and effective solutions down the road.