Overview of Turntables and Robots for Welding

Accuracy is crucial in the rapidly evolving field of industrial automation. Integration of welding robots with welding turntables represents a major improvement in output. When combined with a welding turntable, EVS’s advanced welding robots, which lead the industry in precision and efficiency, provide unmatched welding applications. These tools are vital to numerous sectors because they provide high-quality, dependable welding and expedite production procedures.

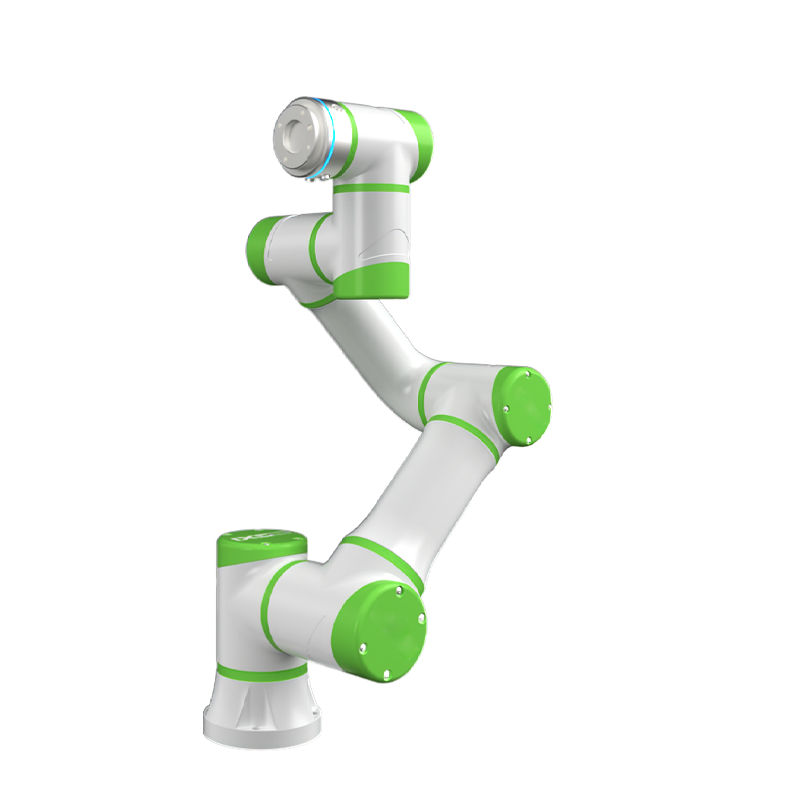

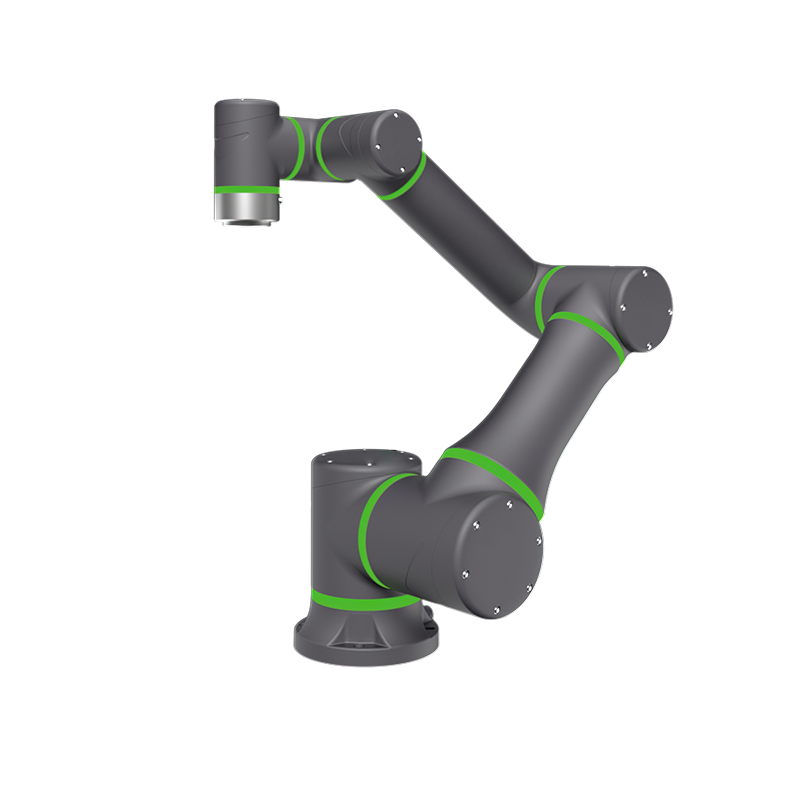

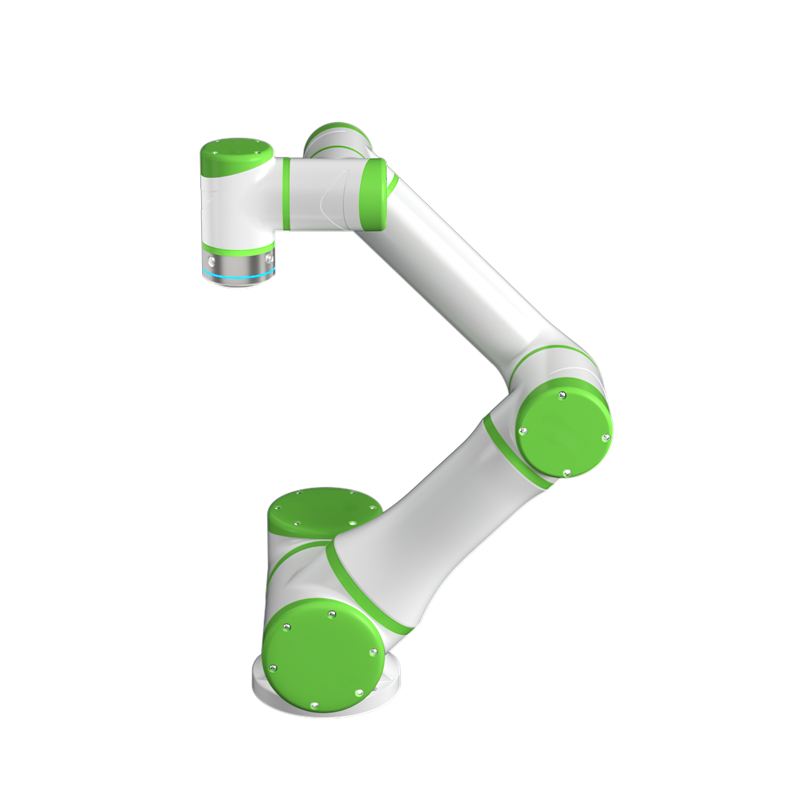

The 6-Axis Robotic Welding System’s Power

Precision and versatility are features built into EVS’s 6-axis welding robots. These welding robots‘ sophisticated control mechanisms guarantee that every weld is completed perfectly. The robot can easily do complicated welding jobs because to its 6-axis architecture, which permits precise motions.

Extra Features:

Advanced Control Systems: Provide accurate welding task execution.

Flexibility: Able to manage a broad spectrum of welding tasks.

Compact Design: Perfect in spaces where there is little room.

Precision: Every weld is supplied with constant precision.

Sturdiness: Designed to endure the rigors of industrial uses.

Increasing Accuracy with Welding turntables

When it comes to intricate welding procedures where precision is essential, this talent is very crucial. Manufacturers may obtain improved weld quality, lower human error, and greatly increase overall production efficiency by combining a welding turntable with EVS’s welding robots.

Further Advantages:

Flexibility: Sets up workpieces for welding at the right angles.

Accuracy of welding robots is improved by precision.

Efficiency: Minimizes the need for human corrections.

Work with EVS welding robots seamlessly through integration.

Productivity: Quickens the welding process without sacrificing quality.

The Partnership Between Welding turntables and Robots

Precision welding’s future lies on the cooperation of welding robots and welding turntables. The welding robots are able to produce consistent, excellent, and repeatable welds because the welding turntable precisely positions the workpiece. Additionally, by minimizing mistakes and cutting down on production time, this integration boosts the manufacturing process’ total productivity.

Advantages of Synergy:

Increased Speed: Quickens the process of welding.

Increased Accuracy: Guarantees that each weld is placed precisely.

Enhanced Efficiency: Shortens production duration and enhances workflow.

Cost reduction: Increases efficiency to cut operating expenses.

Quality assurance ensures that the welds are always of excellent quality.

Utilizing Welding turntables and Robots for Applications

To maintain safety and durability criteria in these industries, one must be able to consistently make high-quality welds. Modern production relies heavily on welding robots because they are an invaluable tool. When combined with welding turntables, welding robots can do complex welding jobs, like as welding massive structures or delicate components.

Principal Uses Incorporate:

Automotive: Guarantees accuracy while welding car parts together.

Aerospace: Essential for precise, safety-sensitive welding jobs.

Large and intricate structures are best welded with heavy machinery.

Electronics: Performs fine welding operations with extreme accuracy.

Widely applicable to many industrial applications is general manufacturing.

In conclusion, Precision Welding’s Future with EVS

The need for precise equipment like welding robots and welding turntables is rising as companies continue to push the limits of automation. EVS is at the forefront of this development, providing cutting-edge technologies that improve welding operations’ accuracy and productivity. Manufacturers may attain unparalleled levels of precision, efficacy, and excellence in their manufacturing procedures by using a welding turntable with EVS’s 6-axis welding robots. With the inventive application of welding robots and welding turntables in contemporary industry, welding has a bright future.

Go to the EVS product pages for these items for further information in-depth:

6-Axis Collaborative Robot with a Payload of 6 kg

Twelve Kilogram Payload Six-Axis Collaborative Robot

To lead the way in industrial accuracy and automation, improve your welding processes with EVS welding robots and welding turntables.