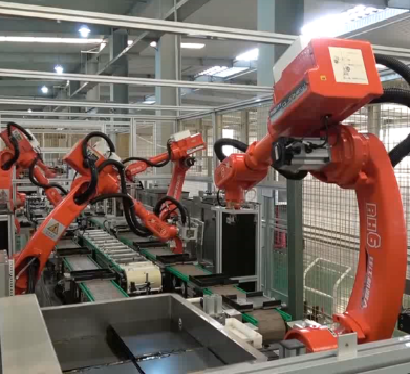

The use of gear boxes and palletizing robots in industrial automation has revolutionized processes by increasing precision and efficiency. Robots that palletize pallets are essential for moving large objects, arranging supplies, and increasing output. These robots provide even more steady and regulated motions when combined with a high-performance gear box, which helps them carry out duties precisely. Palletizing robots improve operational efficiency in areas like transportation, packaging, and storage by automating repetitive and physically taxing processes.

The capacity of a palletizing robot to reliably lift, transport, and stack objects of different weights is the foundation of its efficiency. For the robot to continue operating at such high levels of performance, motion control and torque regulation require a sturdy gear box. In order to ensure accurate and seamless functioning, the gear box helps control the torque distribution and rotating speed of the robotic arm. A palletizing robot would find it difficult to maintain constant precision without a sturdy gear box, particularly when handling large loads in busy settings.

Palletizing robots’ Function in Streamlining Operations

Palletizing robots are designed to increase manufacturing line speed by automating the handling and stacking of items. Palletizing robots save cycle times and boost overall productivity in sectors where throughput and timing are essential. However, a high-performance gear box‘s strength and accuracy are necessary for these robots to operate smoothly. The torque and speed balance are maintained by the gear box, which allows the robot to move smoothly and uninterruptedly from one duty to another.

Production processes are accelerated and enhanced with more dependability when superior gear boxes are paired with palletizing robots. For example, heavy-duty versions with a 180 kg payload, such the QJRB180-1, need a sturdy gear box to provide even power transfer throughout the cycle. Similar to this, the 800 kg payload of the QJRB800-1 is made possible by a well constructed gear box that can support large weights without compromising the arm’s smooth functioning. With this combination, businesses can manage greater material volumes more effectively and with less physical labor.

The Way Gear boxes Increase Robot Performance

Palletizing robots‘ operating precision and robustness are improved by the addition of a high-performance gear box. For tasks requiring perfect stacking or sorting, a gear box makes sure the robot’s arm can move heavy objects with fine control. The gear box also reduces mechanical strain, which increases the robot’s and its parts’ operating life. Palletizing robots would struggle to maintain constant speeds without the stability offered by a dependable gear box, which might result in inefficiencies or more wear and tear.

The gear box helps palletizing robots achieve better positioning and movement precision by controlling power transfer. In sectors where items must be handled carefully to prevent damage, such manufacturing, food & beverage, and pharmaceutical, this precision is especially crucial. Palletizing robots and cutting-edge gear boxes work together to provide efficient processes that increase output while guaranteeing material safety, which lowers operating costs and the number of faults.

High-Capacity Palletizing robots’ Advantages

Industrial processes can profit greatly from the combination of high-capacity gear boxes with palletizing robots. First, by automating physically taxing and repetitive operations, palletizing robots lessen the need for human labor. These robots are capable of effortlessly handling large weights because they use gear boxes to provide smooth, controlled movement. The QJRB180-1 and QJRB800-1 versions, for instance, are made to manage heavy loads with accuracy. These robots can carry, move, and stack large objects more effectively than human labor could thanks to a gear box.

Palletizing robots with gear boxes not only boost output but also provide increased uniformity and safety in manufacturing settings. Automation of heavy lifting duties ensures that materials are handled carefully and precisely while lowering the danger of workplace hazards. In addition, the system’s usage of a gear box lowers the possibility of mistakes or mishaps by guaranteeing that the robotic arm moves smoothly with each movement. This automation technology guarantees a more dependable and safe work environment in addition to increasing production speed.

Palletizing robots and Gear boxes: The Future of Industrial Automation

Palletizing robots and gear boxes will become more important in industrial automation as technology develops. Advancements in gear box technology will provide more accurate control over robotic motions, allowing palletizing robots to do ever more intricate jobs with greater precision. More cycle time savings and increased production flexibility are anticipated as a result of these developments. The use of gear box and palletizing robots together will continue to be essential for optimizing manufacturing procedures as industries change. As palletizing robots get bigger and more intricate, we should anticipate seeing even more advanced gear boxes in the future. It is probable that these systems will incorporate artificial intelligence and machine learning capabilities, enabling palletizing robots to adjust to varying circumstances instantly.

In summary

In summary, the integration of sophisticated gear boxes with high-capacity palletizing robots has transformed the way many sectors manage bulky goods and optimize their manufacturing procedures. Palletizing robots provide the accuracy and speed needed for large-scale manufacturing, while gear boxes provide steady, reliable operation. Together, these technologies save operating costs, increase safety, and boost production. Palletizing robots and high-performance gear boxes will continue to be at the forefront of innovation in industrial automation, increasing efficiency and precision in manufacturing processes around the globe.