As modern technologies are integrated, the industrial landscape is changing. In smart logistics, the welding turntable is one such technology that is becoming more and more popular. By enabling workpieces to be handled effectively, these turntables improve production speed, precision, and dependability. In order to optimize operations in a variety of sectors, welding turntables are transforming smart logistics, as this article will examine.

Knowing How to Use Welding turntables in Smart logistics

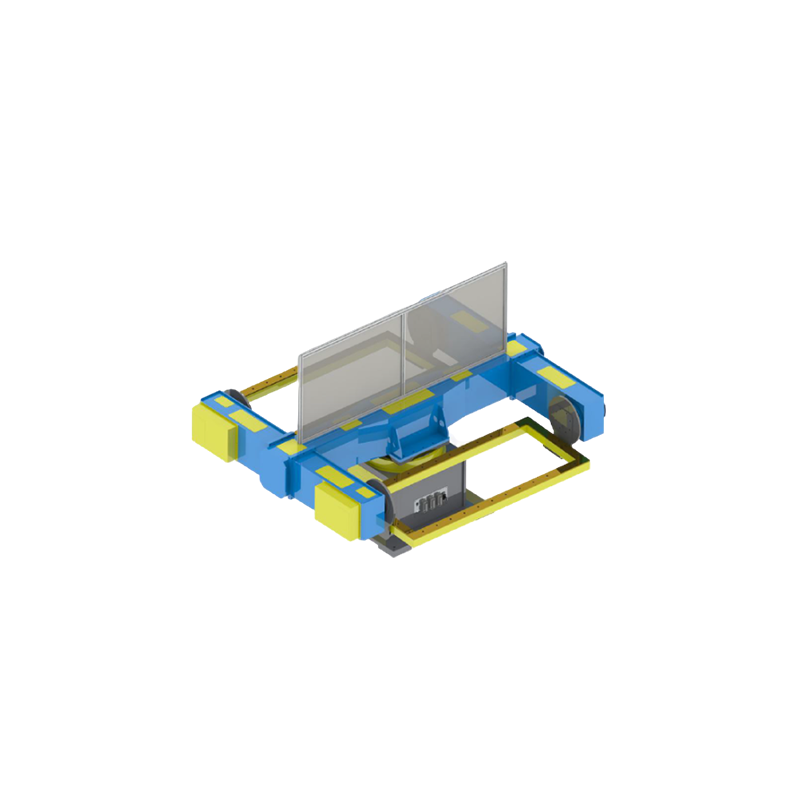

A welding turntable is a multipurpose tool for positioning workpieces for the best possible welding precision. These turntables spin the workpiece, making it simple for the welder or welding robot to reach various perspectives. Welding turntables can enhance material handling and streamline welding processes to integrate with automated logistics systems when it comes to smart logistics. Their accuracy, reliability, and capacity to manage workpieces of different sizes make them an essential part of contemporary production and storage.

Increased Productivity using Welding turntables

Retaining competitiveness in smart logistics requires efficiency. Because they guarantee that every weld is completed with constant accuracy, welding turntables are crucial. Turntables allow for continuous rotation of the workpiece without requiring physical assistance. This minimizes downtime and human mistake, making it particularly helpful when used with automated systems. A speedier production cycle, improved weld quality, and increased throughput are the outcomes, all of which are necessary to achieve ideal smart logistics.

Combining Automation with Robotic Systems

The fact that welding turntables are compatible with robotic systems is one of their biggest advantages. Businesses may include automated welding equipment or welding turntables with robotic arms to produce a more complete and effective smart logistics solution. Robots provide the welding, and turntables offer the exact placement. By enabling smooth automation, this combination lowers labor costs and eliminates the need for manual intervention. Because of this degree of integration, welding turntables are a vital component of contemporary automated production lines.

Why Adaptability and Flexibility Are Important

The capacity to adjust to shifting needs is essential for success in today’s industry. The versatility required for a range of welding applications, from tiny parts to big, heavy objects, is provided by welding turntables. They rotate smoothly and are simple to modify to fit varying workpiece size. Because of this flexibility, businesses may swiftly modify their welding procedures to satisfy shifting client needs or new project specifications in smart logistics, preserving efficiency without compromising quality.

Benefits of Welding turntables in Terms of Cost

The implementation of welding turntables in smart logistics lowers total expenses while simultaneously increasing efficiency. Turntables contribute to a steady and effective welding process, which minimizes waste, rework, and labor expenses. Welding turntables are used to automate welding, which consistently produces high-quality welds with fewer faults and less waste. Additionally, welding turntables are an affordable way to improve smart logistics since lower human labor costs and higher productivity have a direct influence on profitability.

Turntable Welding: A Revolution in Logistics Efficiency

In order to increase production, decrease mistakes, and improve efficiency, the use of welding turntables in smart logistics is quickly becoming the norm. Welding turntables are crucial in the industrial and shipping industries due to their capacity to increase flexibility, precision control, and automation compatibility. Businesses that want to stay ahead of the competition and uphold operational excellence should think about including welding turntables into their automation and logistics plans in order to enhance their production operations.