Introduction

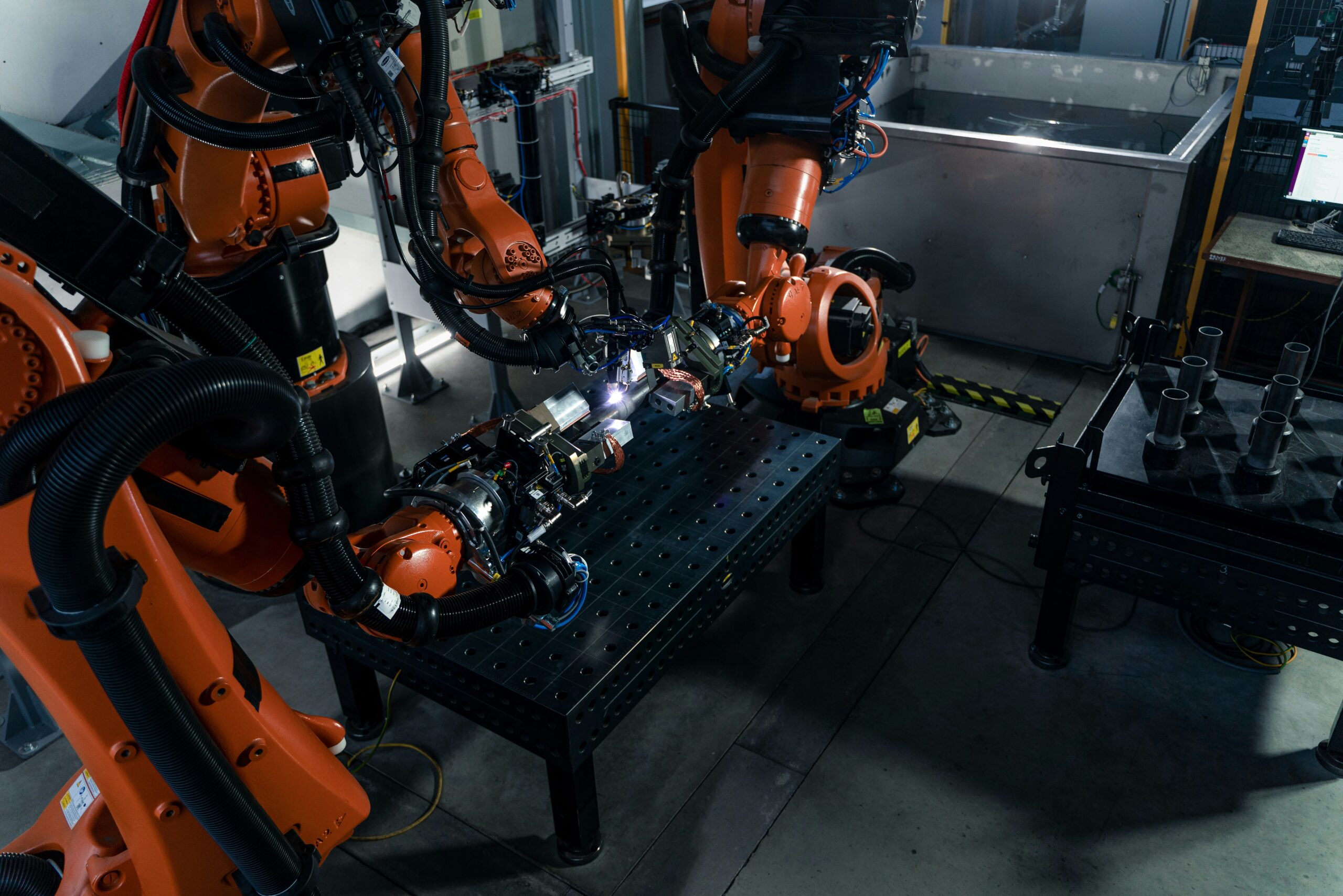

Productivity and precision assurance are critical factors in the rapidly evolving contemporary manufacturing industry. Critical to success is the capacity to manufacture high-quality products on a consistent basis while maintaining efficiency and cost-effectiveness. The integration of laser welding robots signifies a substantial progression in the pursuit of attaining this objective. When integrated with specialized robot tracks, these robots offer an unparalleled degree of accuracy and versatility, thus instigating a fundamental change in the welding industry. This article presents a comprehensive examination of the importance of robot tracks and laser welding robots in modern manufacturing, with a particular focus on their functionalities, technical attributes, and practical applications.

A Comprehension of Laser Welding Robots

An Exposition on Laser Welding Robots

Robots for laser welding are mechanized devices that execute welding operations with extreme rapidity and accuracy. By utilizing laser beams to melt and join materials, they are capable of producing precise and robust welds. The principal benefits of laser welding robots consist of:

Laser welding permits meticulous regulation of the welding procedure, which culminates in welds of superior quality that exhibit minimal deformation.

The rate at which these robotic systems perform welding procedures exceeds that of manual approaches, consequently resulting in increased efficiency.

Laser welding robots possess the ability to thinly weld aluminum, copper, stainless steel, and carbon steel, among other materials.

The QJR6-2000H Welding Machine

The QJR6-2000H welding robot serves as an embodiment of the functionalities that contemporary laser welding robots are capable of. The following is an exhaustive exposition of its fundamental attributes and technical particulars:

Descriptive of the Product

Load: 6 kilograms

Distance Reached: 2014mm

Six-Gear Gap Axis Structure of Adjustment: Enhances joint precision.

A hollow structure featuring a wrist U-shaped design improves the stiffness of joint support, thereby enhancing flexibility.

An operating noise reduction structure is the result of a patented design.

Antishake Optimization: Minimizes control error, enhances operating stiffness, and reduces end clearance.

Reiterate the position Precision: ±0.08mm

Spread: 2014mm

Applicable to carbon steel, stainless steel, aluminum, copper, and more on the working piece.

Technical Specifications

The QJR6-2000H model

Six is the axis number.

Payload: six kilograms

Positioning Repetition: ±0.08mm

Armspan maximum: 2014mm

Range of Motion: J1: ±175º; J2: +159º; -95º

J3: ﹢95º,﹣125º

J4: ±183º

J5: +129, -126°

J6: ±360º

J1: 189º/s J2: 189º/s J3: 189º/s J4: 378º/s Maximum Speed

J5: 320º/s J6: 687º/s

J4 is permitted 8.81N.m, J5 is also 8.81N.m, and J6 is 3.14N.m.

Moment of Inertia: J4 = 0.2 g/m2.

J6: 0.03kg.m<; J5: 0.2kg.m²

Weight of Robot: 230 kg Capacity of Power: 3.4 VA

Weight of Cabinet: 130 kg

10% three-phase, four-wire 380V as the source

Form of Installation: Ground, Ceiling

Implementation: Welding

Robotic Tracks’ Importance in Laser Welding

A Brief Overview of Robot Tracks

The utilization of robot tracks is vital for optimizing the operation of laser welding robots. The tracks facilitate consistent and accurate movement for the robots, enabling them to traverse diverse workpieces with ease and precision. These are the principal advantages of utilizing robot tracks:

Expanded Operational Range: The utilization of robot tracks empowers laser welding robots to traverse more expansive regions.

Enhanced Flexibility: Tracks enable robotic systems to traverse intricate geometries and gain access to areas that are challenging to enter.

Enhanced Precision: Throughout the welding process, the welding robots maintain a high degree of accuracy due to the stability provided by the robot tracks.

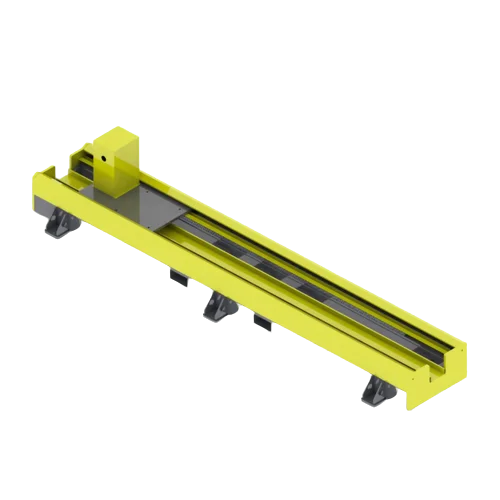

Aspects Technical Regarding EVS Robot Tracks

The EVS robot tracks are specifically engineered to enhance the functionalities of laser welding robots. The following is an exhaustive exposition of their fundamental attributes and technical particulars:

Descriptive of the Product

Light-duty Single Axis Ground Mounting Robot Servo Walking Rail as a Walking Method

The GS-SXW-Z-L-XX model

Among its many uses are welding, cutting, handling, machining, painting, and gluing.

Length Standard: 4000mm

In excess of Customizable standard lengths are 1000mm, 2000mm, and 4000mm.

Method of Mounting: Ground Mounting

Dimensions in total: L mm 910 mm 750 mm (L varies depending on the motor used).

Protection: Semi-enclosed sheet metal

Lubricating Mechanism: Auto-lubrication

Fuel Pump Current: AC220V

Chain of Forces Position of Mounting: Center

Precise Technical Particulars

Rating: 300-3000kg Accuracy of Repeat Positioning: ±0.10mm (for payloads below 1000kg) and ±0.15mm (for payloads between 1000 and 3000kg).

QJR6-2000H Integration with EVS Robot Tracks

Welding Robot Synergy Utilizing Robot Tracks

The integration of the QJR6-2000H welding robot with EVS robot tracks offers significant advantages in terms of precision, flexibility, and efficiency. Listed below are several key benefits:

Improved Precision: The stability and accuracy provided by the robot tracks ensure that the QJR6-2000H maintains its high repeat positioning accuracy of ±0.08mm.

Enhanced Flexibility: The extended range and maneuverability offered by the tracks allow the robot to reach more areas and perform complex welding tasks.

Enhancement in Productivity: The amalgamation of rapid motion and accurate regulation diminishes the duration of welding operations and augments overall output.

Compatibility of Themes

The tracks of the QJR6-2000H welding robot and the EVS robot are engineered to operate in perfect harmony. The following are some technical compatibility aspects:

Payload Capacity: With a range of 300kg to 3000kg payload capacity, the tracks are adequate for the QJR6-2000H’s 6kg payload.

High Repeat Positioning Accuracy: Consistent and precise welding outcomes are guaranteed by the high positioning accuracy provided by both the robot and the tracks.

Installation Methods: The tracks are adaptable to various manufacturing configurations, as they can be mounted on the ceiling or the ground.

Case Studies and Practical Implementations

Case Study 1: The Automotive Sector

Manufacturing high-quality auto parts in the automotive industry requires exactitude and velocity. By combining the QJR6-2000H welding robot with EVS robot tracks, the following advantages have been successfully realized in this industry:

Enhanced Accuracy: The elevated repeat positioning accuracy guarantees the uniformity and robustness of every weld.

Decreased Production Time: The welding tasks are completed in a shorter amount of time due to the rapid motion capabilities of the robot and tracks.

Enhanced efficiency results in reduced expenditures on production and increased profitability.

Case Study 2: The Aerospace Sector

Particular attention must be paid to precision and dependability in the aerospace sector, where lightweight materials such as titanium and aluminum are utilized. In this industry, the QJR6-2000H and EVS robot tracks have proven to be invaluable assets by providing:

Enhanced Precision: Even in high-stress environments, the welding robot executes precise welds due to the stability of the tracks.

The robot’s adaptability to a variety of materials enables it to be utilized in a wide range of aerospace applications.

Noise reduction and antishake optimization capabilities enhance the performance and dependability of the robot.

Case Study 3: Manufacturing in General

To satisfy a wide range of production requirements, adaptability and customization are fundamental in general manufacturing. The following are the benefits of combining the QJR6-2000H welding robot with EVS robot tracks:

Tailored Solutions: The tracks are adaptable to particular specifications, including variations in length and payload capacities.

Enhanced Flexibility: The robot’s capacity to navigate intricate geometries renders it well-suited for an extensive array of manufacturing procedures.

Optimised Productivity: The precision control and rapid motion enhance the overall efficiency of the manufacturing process.

To conclude

The integration of laser welding robots with robot tracks represents a significant advancement within the manufacturing industry. The QJR6-2000H welding robot, when utilized in conjunction with EVS robot tracks, exhibits remarkable precision, versatility, and output, establishing it as an indispensable asset in numerous sectors including aerospace, automotive, and general manufacturing. It is anticipated that the ongoing advancement of technology will foster a harmonious relationship between welding robots and robot tracks, culminating in enhanced manufacturing procedures that yield superior products and heightened levels of productivity.