Our collaborative robots are divided into three series

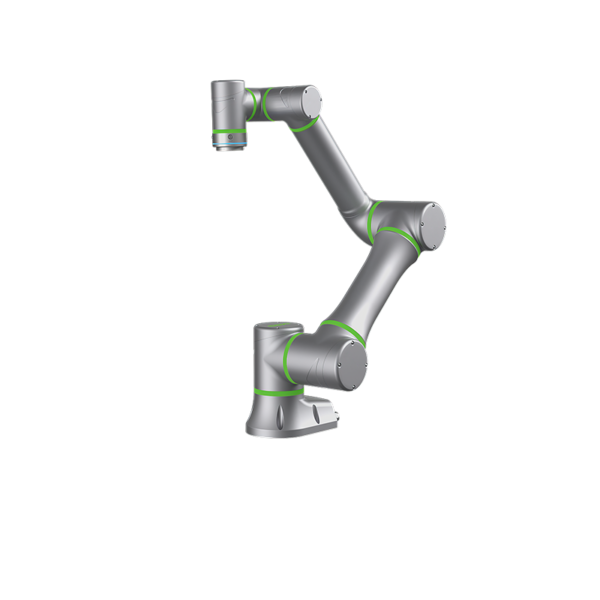

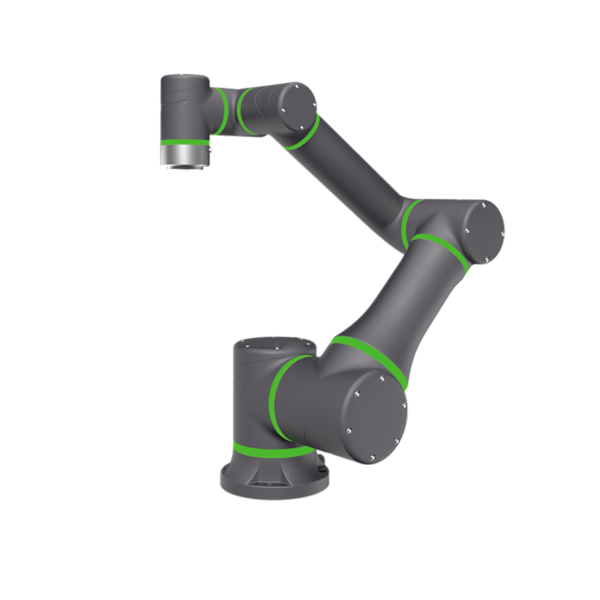

G series (industrial grade): suitable for industrial fields, including handling, welding, palletizing, screw locking, grinding and other tasks.

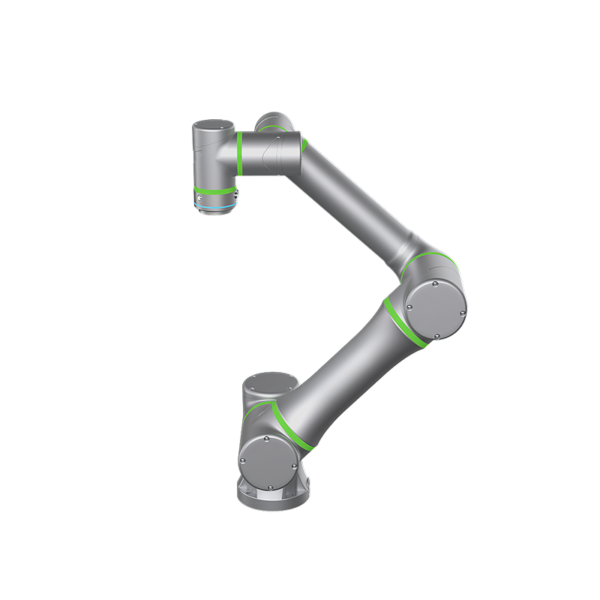

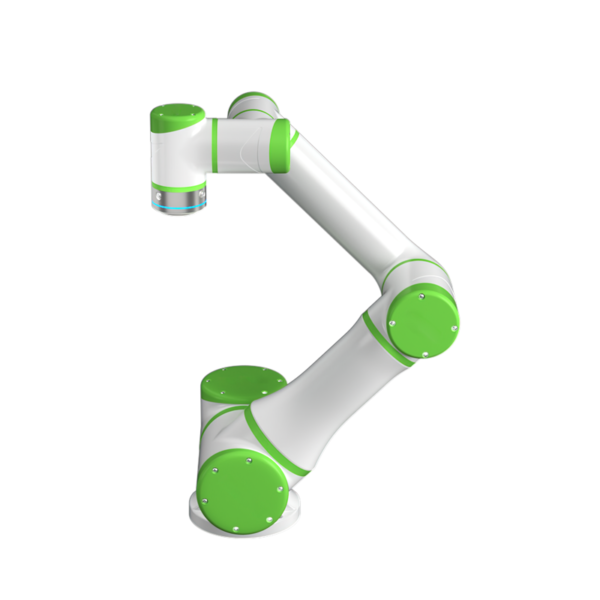

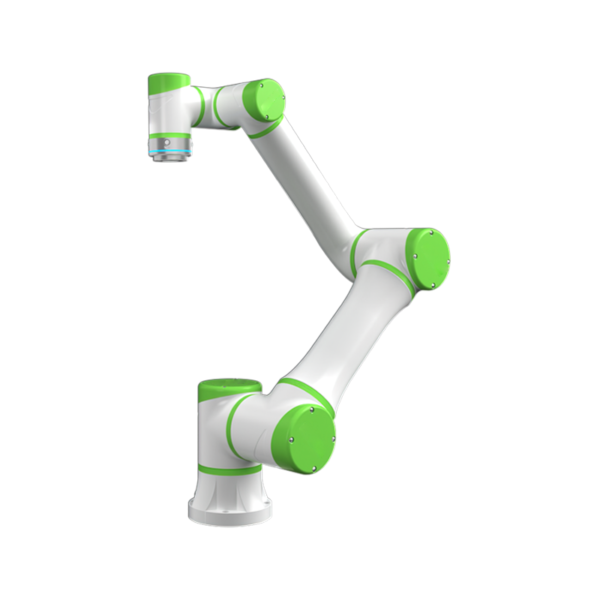

C series (consumer grade): widely used in the service industry, such as coffee robots and noodle robots in the food industry.

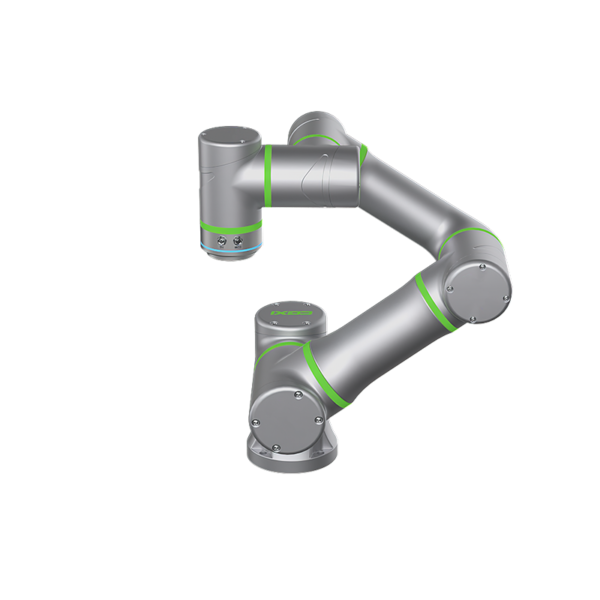

X series (explosion-proof level): designed for use in special environments, such as intelligent shadowless surgical lights in the healthcare industry.

| Model | CR6-DK-093S1-CS01 | |

| Robot Arm Net Eeight (without cables) | 22kg | |

| Payload | 6KG | |

| Armspan | 917mm | |

| Degree of Freedom | 6 | |

| Motion Range | Joint 1 | ±360° |

| Joint 2 | ±360° | |

| Joint 3 | ±165° | |

| Joint 4 | ±360° | |

| Joint 5 | ±360° | |

| Joint 6 | ±360° | |

| Motion Speed | Joint 1 | 180°/s |

| Joint 2 | 180°/s | |

| Joint 3 | 180°/s | |

| Joint 4 | 180°/s | |

| Joint 5 | 180°/s | |

| Joint 6 | 180°/s | |

| EOA Maximum Speed | 2m/s | |

| Repeat Positioning Accuracy (maximum) | ± 0.03mm | |

| Absolute Positioning Accuracy (maximum) | 0.5mm | |

| Control Bus/Frequency | EtherCAT/1kHz | |

| Installation Method | any angle | |

| Typical Power | 200W | |

| Material | Aluminum alloy | |

| Ambient Temperature | -5°C~55°C | |

| Working Environment (humidity) | 5%~90%RH (no condensation) | |

| Cable Length | 5m | |

| IP GRADE | IP54 | |

| Noise | ≤60dB | |

| Tool End IO Port | digital input*2,digital output*2, analog input*2,output power supply24V/1A*1 | |

| Tool End Communication Port | EtherCAT*1,RS485*1, output power supply24V/1A*1 | |

| Model | CR6-096S1-W-CS01 | |

| Robot Arm Net Eeight (without cables) | 21kg | |

| Payload | 6KG | |

| Armspan | 917mm | |

| Degree of Freedom | 6 | |

| Motion Range | Joint 1 | ±360° |

| Joint 2 | ±360° | |

| Joint 3 | ±165° | |

| Joint 4 | ±360° | |

| Joint 5 | ±360° | |

| Joint 6 | ±360° | |

| Motion Speed | Joint 1 | 180°/s |

| Joint 2 | 180°/s | |

| Joint 3 | 180°/s | |

| Joint 4 | 180°/s | |

| Joint 5 | 180°/s | |

| Joint 6 | 180°/s | |

| EOA Maximum Speed | 2m/s | |

| Repeat Positioning Accuracy (maximum) | ± 0.03mm | |

| Absolute Positioning Accuracy (maximum) | 0.5mm | |

| Control Bus/Frequency | EtherCAT/1kHz | |

| Installation Method | any angle | |

| Typical Power | 200W | |

| Material | Aluminum alloy | |

| Ambient Temperature | -5°C~55°C | |

| Working Environment (humidity) | 5%~90%RH (no condensation) | |

| Cable Length | 5m | |

| IP GRADE | IP66 | |

| Noise | ≤60dB | |

| Tool End IO Port | digital input*2,digital output*2, analog input*2,output power supply24V/1A*1 | |

| Tool End Communication Port | EtherCAT*1,RS485*1, output power supply24V/1A*1 | |

EVS Robotics is an industrial robot supplier providing automation solutions and support to our customers. Our products are used in industrial automation such as welding, painting, handling, palletizing, bending and polishing. And after years of development, our core technology has been widely used in different industries like Automotive, Metal Industry, Food & Beverage, Medical & Pharmaceutical and more.

Copyright ©EVS TECH CO., LTD All rights reserved.All materials not authorized may not be redirected or for other usages.

en

en