Multi-station operation, Autonomous movement.

Without programming and teaching, all models can independently scan and extract workpiece model and weld information.

Pre-install typical workpiece model and welding process, double-wire welding, multi-layer and multi-pass, and weld any workpiece.

Pre-install typical workpiece model and welding process, double-wire welding, multi-layer and multi-pass, and weld any workpiece.

Combining plasma (suitable for thin plates below 50mm) with flame cutting (can reach 100mm+thick plates)

For different types of customers, high, medium and low-priced products have the adaptability of full market coverage.

With the help of self-learning intelligent engine, whole process automation, seamless cross-platform integration, one-button configuration experience and AI decision support system, the efficiency of welding and cutting processes can be improved, human error can be reduced, operation and data linkage can be achieved, operation process can be simplified, and scheme optimization and decision assistance can be achieved.

| Parameter / Model | Welding standard model EVS-UWS11V10 | Welding lifting paragraph EVS-UWL15V10 | Welding standard model EVS-CS14V10 | Welding lifting paragraph EVS-CL14V10 | Welding standard model EVS-HS15V10 | Welding lifting paragraph EVS-HL15V10 | Welding standard model EVS-MS15V10 | Welding lifting paragraph EVS-ML15V10 | Welding EVS-DW10V10 | Welding EVS-FW16V10 | Cutting EVS-UC | Cutting EVS-TS10V10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Total Power | 36 KVA | 37 KVA | 36.5 KVA | 37.5 KVA | 50 KVA | 51 KVA | 50 KVA | 51 KVA | 30 KVA | 30 KVA | 47 KVA | 60 KVA |

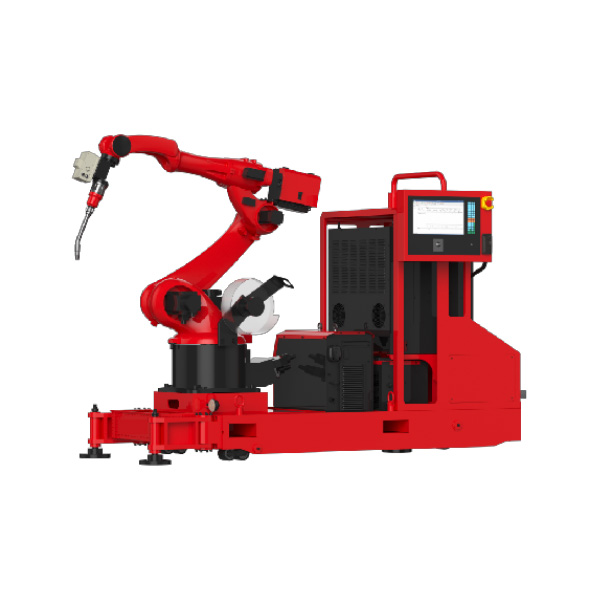

| Photo |  |

|

|

|

|

|

|

|

|

|

|

|

| Power Supply | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz | 3-phase 5-wire 3x380V±10%/50Hz |

| Power Supply Mode | Quick-plug | Quick-plug | Quick-plug | Quick-plug | Reel supply | Reel supply | Reel supply | Reel supply | Quick-plug | Quick-plug | Quick-plug | Reel supply |

| Equipment Weight | 1650kg (varies with model) | 2200kg (varies with model) | 1550kg (varies with model) | 2050kg (varies with model) | 3200kg (varies with model) | 3800kg (varies with model) | 3200kg (varies with model) | 3800kg (varies with model) | 1000kg (varies with model) | 1500kg (varies with model) | 3500kg (varies with model) | 2800kg (varies with model) |

| Dimensions | 2800mm×1500mm×1600mm | 3500mm×1500mm×2000mm | 2900mm×1700mm×1750mm | 3400mm×1700mm×2000mm | 3400mm×1500mm×2400mm | 3400mm×1500mm×2400mm | 3400mm×1500mm×2400mm | 3400mm×1500mm×2400mm | 1550mm×860mm×1500mm | 2500mm×900mm×1800mm | 3200mm×1600mm×2300mm | 2600mm×1400mm×2150mm |

| Vision Accuracy | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm |

| Scanning Frame Rate | 2000fps/s | 2000fps/s | 2000fps/s | 2000fps/s | 2000fps/s | 2000fps/s | 2000fps/s | 2000fps/s | 2000fps/s | 2000fps/s | 2000fps/s | 2000fps/s |

| Standard Vision | RX01 | RX01 | RX01 | RX01 | RX01 | RX01 | RX01 | RX01 | RX01 | RX01 | RX01 | RX01 |

| Battery Voltage | 48V | 48V | 48V | 48V | / | / | / | / | / | 48V | 48V | / |

| Battery Capacity | 73ah | 73ah | 73ah | 73ah | / | / | / | / | / | 32ah | 73ah | / |

| Walking Power Supply | DC48V | DC48V | DC48V | DC48V | / | / | / | / | / | DC48V | DC48V | / |

| Robot Reach Range | 2010mm (varies with model) | 2010mm (varies with model) | 2010mm (varies with model) | 2010mm (varies with model) | 2272mm (varies with model) | 2272mm (varies with model) | 2272mm (varies with model) | 2272mm (varies with model) | 1300mm (varies with model) | 2010mm (varies with model) | 2010mm (varies with model) | 1831mm (varies with model) |

| Walking Drive | Three-wheel | Three-wheel | Track | Track | Omnidirectional | Omnidirectional | Mecanum wheel | Mecanum wheel | Three-wheel | Three-wheel | Three-wheel | Track |

| Control Mode | Wireless Remote | Wireless Remote | Wireless Remote | Wireless Remote | Laser Radar | Laser Radar | Laser Radar | Laser Radar | Wireless Remote | Manual | Wireless Remote | Wireless Remote |

| Walking Speed | 4km/h | 4km/h | 1km/h | 1km/h | 2.2km/h | 2.2km/h | 1km/h | 1km/h | 2.5km/h | 2.5km/h | 4km/h | 1km/h |

| Lifting Stroke | / | 700mm | / | 700mm | / | 700mm | / | 700mm | / | / | 1000mm | / |

| Operating Temperature | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) | 0~45℃ (operating); -20~60℃ (storage) |

| Humidity | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) | ≤90%RH (no condensation) |

Flexible placement of workpieces

The workpiece can be placed freely without the need for fixture positioning.

Good product mobility

More precise omnidirectional movement, suitable for working environments with flat and hard surfaces.

Dual mode of autonomous navigation and manual remote control, easy to operate.

The range of arm extension lifting is expanded, suitable for welding higher workpieces (lifting version).

3D Visual Recognition

No programming or teaching required, independently scan the workpiece model and extract weld seam information.

AI technology

AI technology utilizes machine vision and deep learning to achieve “welding as soon as possible”, accurately identifying weld seams and autonomously adjusting parameters, improving welding intelligence and automation, and adapting to complex scenes and high difficulty tasks.

Flexible placement of workpieces

The workpiece can be placed freely without the need for fixture positioning. Users can also equip themselves with self purchased roller frames, which can facilitate cutting of tanks or cylinders in different directions.

Good product mobility

Power battery, wireless remote control driving, flexible mobility.

Low requirement for ground flatness, suitable for workshop operations.

The range of arm extension lifting is expanded, suitable for cutting holes and beveling large tanks.

3D Visual Recognition

Free from autonomous scanning of workpiece models, the cutting starting point, middle point, and end point can be determined based on posted QR codes, marked points, or manually selected points, and the control points can be fitted into smooth curves to generate cutting paths, controlling the robot to cut smoothly.