Welding Positioner/Turntable Robot Supplier

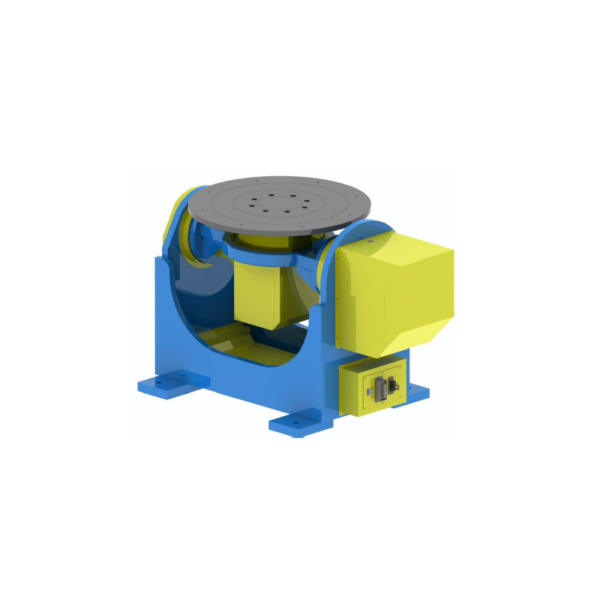

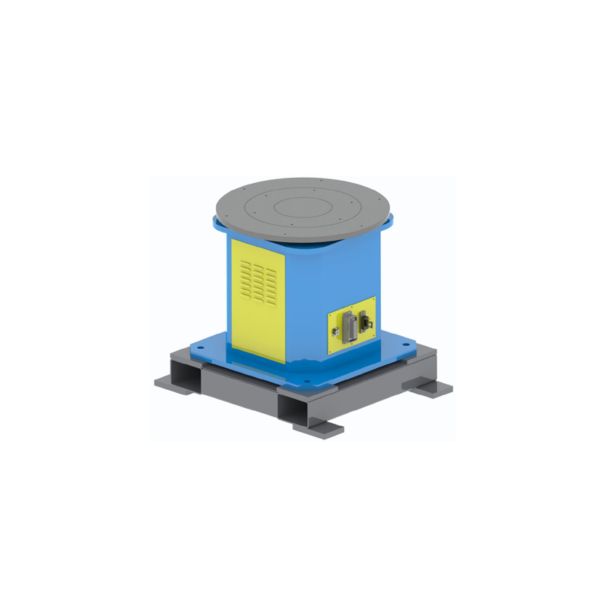

EVS offers high-quality rotary welding positioners for sale which are important components of robotic automation in welding applications. Our welding positioners help ensure the accuracy and quality of your overall production which are critical in robotic welding systems. They drive productivity by minimizing system downtimes and automating tasks that are impossible without machines that have rotational capabilities. EVS has single-axis, two-axis, and three-axis welding positioners that can effectively hold parts in a repeatable and predictable position for welding robots. We also have small welding positioners that we can customize to meet your production line’s specific requirements.

EVS Welding Positioner Advantages

Brass Conductive Material: The conductive material used was brass which has excellent electrical conductivity. It is integral-isolated to ensure the safety of the other components.

Stress-Relieved Components: The fixing base and gyration main spindle cases are stress-relieved which ensures the accuracy, stability, and durability of the robots.

High-Quality Servo Motor & Reducer: The RV reducers and AC servo motors guarantee a low failure rate, high positioning accuracy, and high gyration stability.

EVS Welding Positioner Applications

EVS welding positioners can provide you with the flexibility you need to hold, position, and reposition components in various sizes and shapes from simple and small parts, like small cylinders and metal frames, to large boxy and tubular parts. Robotic welding applications include heavy equipment, automotive, and aerospace industries.

1. Regarding the tail box structure:

The tail box is a concentric shaft structure. It can bring the following two significant advantages:

(1) If there is an eccentricity problem in the structure, that is, the actual center of gravity shifts, our concentric axis structure will bring greater bearing capacity and make the structure stronger.

(2) If there is a tolerance between the fixtures or the workpiece itself, the concentric shaft structure of our positioner has a tolerance within 1cm in the length direction and can be connected to the corresponding hole position to avoid installation failures due to tolerances.

2.About Process flow:

Our company has a complete annealing process, which prevents the equipment structure from deforming, which makes our positioners more durable and highly precise.

3.production methods:

90% of our positioner process uses robot welding, and we are the only manufacturer in China that uses robots to weld positioners. A large number of robots participate in our production, which results in higher production costs. However, the quality of our positioners is far ahead of our peers, with higher precision and remarkable stability.

4 .About Design:

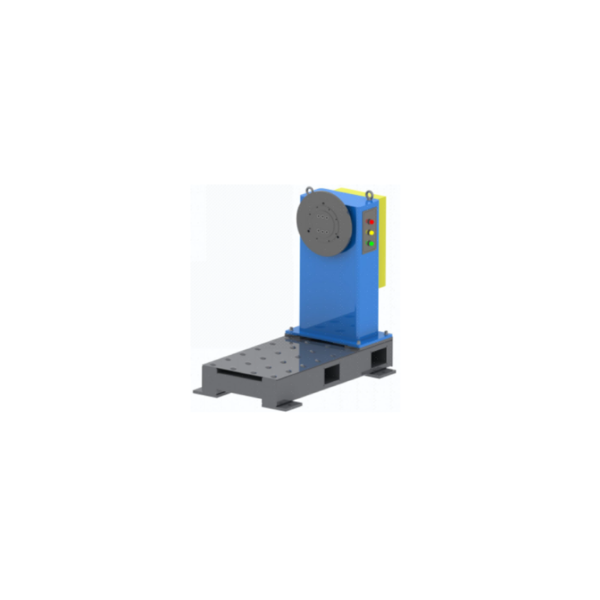

We have strong design capabilities and consider the structure comprehensively. We will help customers consider actual working conditions and actual on-site usage functions. For example: our positioner includes lifting rings to facilitate the use of a crane; it also includes forklift holes to facilitate subsequent transportation.

5. About the cable structure: We have a unique cable structure. The threading structure is convenient for customers to operate. At the same time, each positioner is equipped with three signal lights, making the overall design more user-friendly.)

6.About installation instructions:

Each piece of equipment is attached with detailed installation and commissioning instructions to facilitate customer operation. At the same time, our equipment also comes with maintenance instructions, which are more detailed than those of our peers.)

EVS Robotics is an industrial robot supplier providing automation solutions and support to our customers. Our products are used in industrial automation such as welding, painting, handling, palletizing, bending and polishing. And after years of development, our core technology has been widely used in different industries like Automotive, Metal Industry, Food & Beverage, Medical & Pharmaceutical and more.

Copyright ©EVS TECH CO., LTD All rights reserved.All materials not authorized may not be redirected or for other usages.

en

en