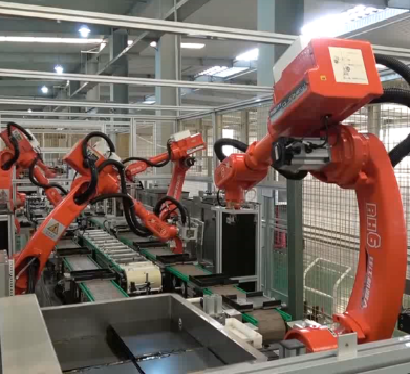

Advanced Robotic Arms for Enhanced Efficiency

EVS 800 kg and 180 kg payload robotic arms are equipped with dedicated high load palletizing robots, which are high-speed and stable. All axes operate at low power output, and the equipment composition is simple. The payload robotic arms can be used in conjunction with dedicated palletizing robots. These advanced robotic arms improve workers’ work efficiency, reduce work pressure, and reduce the cost of manual labor for picking and placing robots. This article explores the functions of these robotic arms and their impact on the manufacturing industry. Using pick and place robots to improve efficiency is crucial for modern manufacturing efficiency. EVS International’s robotic arm has payload capacities of 800 kilograms and 180 kilograms, making it an excellent pick and place robot. These robotic arms ensure precise placement and handling of heavy components.

Continuous Operation and Precision in Manufacturing

The picking and placing robot can automatically perform repetitive tasks, freeing itself from complex operations. The design of the robotic arm ensures high precision and consistent performance. By integrating picking and placing robots, manufacturers can significantly improve efficiency. Using advanced robotic arms to improve workflow, EVS International’s robotic arms provide advanced features that can enhance workflow. These picking and placing robots can efficiently handle multiple tasks. The design of each robotic arm allows for operation in various environments. The continuous operation of the picking and placing robot using a robotic arm does not require rest after a period of work, unlike workers who do not need the picking and placing mechanism at all. It can work tirelessly without fatigue, which definitely greatly improves production efficiency in a certain program. The accuracy of the picking and placing robot ensures high-quality results. Investing in these robotic arms can reduce operating costs and improve efficiency.

Improving Workflow with Advanced Robotic Arms

Robotic arms from EVS International offer advanced features that enhance workflow. These pick and place robots handle multiple tasks efficiently. The design of each robotic arm allows operation in various environments. By incorporating pick and place robots, manufacturers can streamline operations and improve overall workflow. These robotic arms work continuously without fatigue, further enhancing productivity. The precision of pick and place robots ensures high-quality outcomes. Investing in these robotic arms reduces operational costs and improves efficiency.

Advanced robotic arms increase the overall workflow efficiency by reducing manual handling. EVS International’s pick and place robots are designed to handle complex tasks with ease. The robotic arm’s precision ensures that each task is completed accurately. By integrating these robotic arms, manufacturers can enhance their production capabilities. The pick and place robots from EVS International are designed for high-speed operations. This increases the overall productivity of the manufacturing process. These robotic arms can be programmed to handle various tasks, making them highly versatile.

The pick and place robots and palletizing robots robotic arm adopts the CTR-86-ECAT motion controller, which is a combination of advanced PC technology and motion control technology. The system processor of this motion controller adopts the Intel quad core processor J1900, based on the X86 architecture, with a clock speed of up to 2.4GHz, making it an ideal integrated solution for FPGA customers. In addition to providing users with general-purpose computer interfaces such as VGA, LAN, USB2.0/3.0, the CTR-86-ECAT motion controller can also achieve basic functions of general-purpose PCs and provide dedicated interfaces such as ECAT communication interfaces. These latest control systems are mainly designed to enable pick and place robots and palletizing robots to efficiently handle work tasks, and to handle tasks smoothly and flexibly during transportation.

The maximum memory support is 8GB low-power DDR3, and it supports 32GB CFast 2.0 solid-state drive (SSD) for storing user data, configuration information, operating system, etc. These pieces of information enable all controls to be simplified and easily reprogrammed to perform different tasks, ensuring efficient production.

Improve multifunctionality and flexibility

The picking and placing robot has diverse and flexible functions, and can adapt to various tasks. The robotic arms of pick and place robots and palletizing robots can be programmed for different operations. Each robotic arm can be quickly reconfigured to ensure efficient production. These multifunctional robotic arms enable manufacturers of pick and place robots and palletizing robots to effectively meet the constantly evolving production needs. Palletizing robots are mainly responsible for stacking and organizing products, which is very helpful in improving the efficiency of warehousing and logistics. The advanced diagnostic system of Pick and place robots can monitor its performance in real time, detect and solve potential problems in a timely manner. The stable structure of Palletizing robots reduces the need for frequent maintenance, further lowering operating costs.

Enhancing Safety with Robotic Arms

Safety is a top priority in manufacturing. EVS International’s robotic arms are equipped with advanced safety features. These pick and place robots have sensors to detect and avoid obstacles. The robotic arm’s control systems ensure safe operation in dynamic environments. By integrating pick and place robots, manufacturers can create a safer work environment. Each robotic arm is designed to comply with international safety standards. These robotic arms help prevent workplace accidents and injuries.

The extension distance of the “pick and place robots” and “palletizing robots” robotic arms, in their teaching state (TEACH), if the safety switch is in the middle gear, the robots are powered on; If the safety switch is tightly held or released, the robot’s power will be turned off and the motor will be in the braking state.