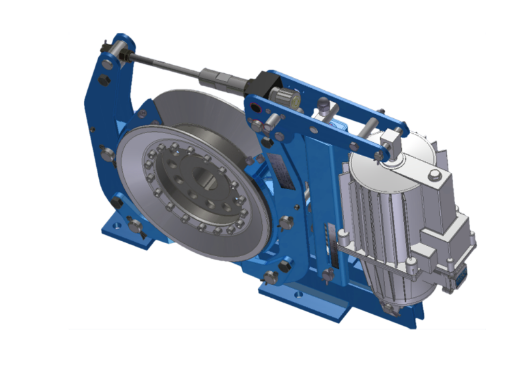

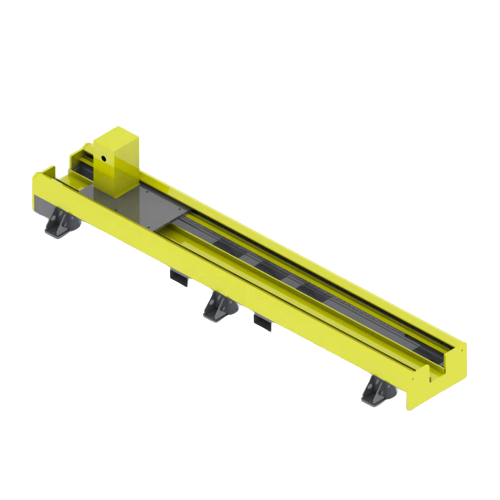

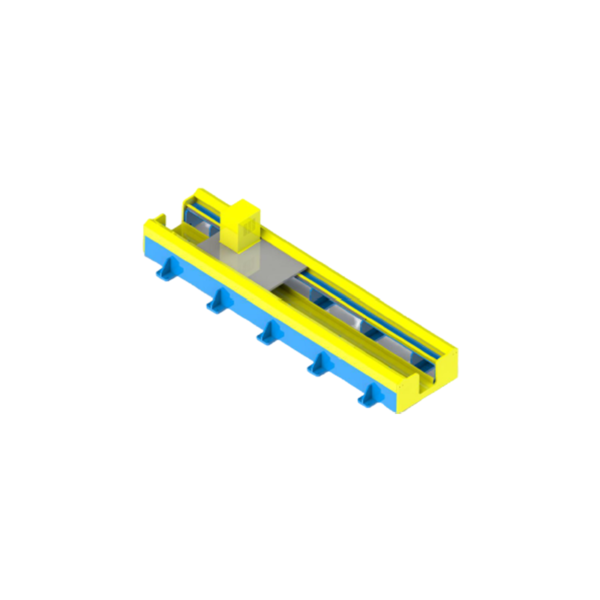

In today’s competitive market where the stakes are narrowing and the manufacturing industry is highly competitive, efficiency, speed, quality, and labor cost reduction have become the key to competitive breakthroughs. Motor gearboxes are essential to optimizing the performance of EVS robot travel tracks. These motor gearboxes ensure the precise control required for a variety of assembly tasks. By integrating high-quality motor gearboxes, the system can provide consistent torque and speed, thereby improving overall efficiency. The motor gearbox is designed to handle high loads, ensuring smooth operation of the robot. This integration reduces downtime and maintenance costs, making your assembly line more efficient.

For more details, please visit EVS.

Enhancing Efficiency with Motorgear boxes

Motorgear boxes are vital in optimizing the performance of EVS’s Robot Walking Rail. These motorgear boxes ensure the precise control needed for various assembly tasks. By integrating high-quality motorgear boxes, the system delivers consistent torque and speed, enhancing overall efficiency. The motorgear boxes are designed to handle high loads, ensuring the robots operate smoothly. This integration reduces downtime and maintenance costs, making your assembly line more productive. Visit EVS to learn more about their innovative solutions.

Industrial-reducers also play a crucial role in enhancing the efficiency of the Robot Walking Rail. These industrial-reducers work seamlessly with motorgear boxes to ensure smooth operation. The industrial-reducers decrease the motor speed while increasing torque, which is essential for handling complex tasks. High-quality industrial-reducers reduce energy consumption and wear and tear on components. The integration of industrial-reducers with motorgear boxes ensures a robust and reliable assembly line. Explore more about EVS’s products here.

Gear boxes are another critical component in EVS’s Robot Walking Rail. These gear box work in harmony with motorgear boxes and industrial-reducers to provide precise movement control. gear box ensure the robots move with high accuracy, crucial for maintaining product quality. The integration of durable gear box reduces the risk of mechanical failures, ensuring continuous operation. This combination of gear box, motorgear boxes, and industrial-reducers creates a highly efficient and reliable system. Discover the benefits of EVS’s gear box here.

Robots from EVS Precision and Accuracy in Manufacturing

EVS’s Robot Walking Rail excels in these areas by using advanced motorgear boxes. These motorgear boxes provide exact control over speed and torque, ensuring precise operations. The motorgear boxes‘ high precision reduces errors and enhances product quality. This precision is critical for industries where accuracy is paramount. Learn more about EVS’s precise motorgear boxes here.

Industrial-reducers are integral to achieving high precision in the Robot Walking Rail system. These industrial-reducers ensure smooth and accurate speed reduction, which is crucial for delicate tasks. By working with motorgear boxes, industrial-reducers enhance the system’s overall precision. High-quality industrial-reducers maintain consistent performance, reducing variability in operations. This combination ensures that every product meets strict quality standards. For more details, visit EVS.

Gear boxes also contribute significantly to the precision of EVS’s Robot Walking Rail. These gear box provide stable and accurate motion control, which is essential for maintaining consistency. gear box work with motorgear boxes and industrial-reducers to ensure seamless operations. The high-quality gear box used in the system reduce mechanical play, enhancing accuracy. This integration results in a highly precise and reliable assembly line. Explore EVS’s precision solutions here.

Maintenance and downtime are money in manufacturing

Maintenance and downtime are critical concerns in manufacturing. EVS’s Robot Walking Rail addresses these issues with durable motorgear boxes. These motorgear boxes are designed for long-lasting performance, reducing the need for frequent maintenance. High-quality motorgear boxes ensure reliable operation, minimizing downtime. This durability translates into significant cost savings over time. Learn more about EVS’s reliable motorgear boxes here.

Industrial-reducers also play a key role in reducing maintenance needs. These industrial-reducers are built to withstand high loads and harsh conditions. By integrating robust industrial-reducers with motorgear boxes, the system ensures consistent performance. This reliability reduces the frequency of maintenance interventions. High-quality industrial-reducers also extend the lifespan of other components, further reducing downtime. Explore EVS’s durable industrial-reducers here.

Gear boxes in the Robot Walking Rail system are designed for durability and minimal maintenance. These gear box work seamlessly with motorgear boxes and industrial-reducers to provide reliable performance. High-quality gear box reduce wear and tear, extending the system’s operational life.

What robotic automation needs most is flexibility and adaptability

Flexibility and adaptability are the soul of manufacturing and robotic automation.EVS’s Robot Walking Rail enhances flexibility with versatile motorgear boxes. These motorgear boxes can be easily adjusted to meet changing production needs. The motorgear boxes‘ adaptability ensures that the system can handle various tasks efficiently. This flexibility makes the assembly line more responsive to market demands. Discover more about EVS’s adaptable motorgear boxes here.

Industrial-reducers contribute to the system’s flexibility by providing adjustable speed and torque settings. These industrial-reducers work with motorgear boxes to adapt to different operational requirements. The industrial-reducers’ versatility ensures that the assembly line can switch between tasks smoothly. This adaptability reduces the time and cost associated with reconfiguring the line. Learn more about EVS’s flexible industrial-reducers here.

Gear boxes in the Robot Walking Rail system are designed for adaptability. These gear box can be easily reconfigured to meet different production needs. Working with motorgear boxes and industrial-reducers, gear box ensure seamless transitions between tasks. This flexibility enhances the system’s overall productivity. For more information on EVS’s adaptable gear box, visit EVS.

Top priority: Enhance security and compliance

EVS’s Robot Walking Rail incorporates safe motorgear boxes. These motorgear boxes are designed to operate reliably under stringent safety standards. High-quality motorgear boxes minimize the risk of accidents, ensuring a safe working environment. This commitment to safety helps maintain compliance with industry regulations. Discover EVS’s safe motorgear boxes here.

Industrial-reducers also enhance safety by providing stable and controlled movements. These industrial-reducers work with motorgear boxes to ensure smooth and safe operations. The industrial-reducers’ reliability reduces the risk of mechanical failures, enhancing safety. By integrating high-quality industrial-reducers, the system maintains compliance with safety standards. Learn more about EVS’s safety-focused industrial-reducers here.

Gear boxes in the Robot Walking Rail system are designed with safety in mind. These gear box ensure reliable power transmission, minimizing the risk of accidents. Working with motorgear boxes and industrial-reducers, gear box provide stable and safe operation. This integration enhances overall system safety and compliance.

Sustainability and energy efficiency are our future direction and criteria for progress

Sustainability is essential in modern manufacturing. EVS’s Robot Walking Rail promotes sustainability with energy-efficient motorgear boxes. These motorgear boxes reduce energy consumption, minimizing the environmental impact. High-quality motorgear boxes ensure optimal performance with lower energy usage. This efficiency supports sustainability goals. Discover more about EVS’s energy-efficient motorgear boxes here.

Industrial-reducers also enhance energy efficiency by optimizing power use. These industrial-reducers work with motorgear boxes to ensure efficient operation. The industrial-reducers’ design reduces energy waste, supporting sustainability. High-quality industrial-reducers extend the system’s operational life, reducing waste. Learn more about EVS’s sustainable industrial-reducers here.

Gear boxes in the Robot Walking Rail system are designed for energy efficiency. These gear box ensure efficient power transmission, reducing energy consumption. Working with motorgear boxes and industrial-reducers, gear box enhance overall system efficiency. This integration supports sustainability and reduces operational costs. For more information on EVS’s energy-efficient gear box, visit EVS.

Conclusion

EVS’s Robot Walking Rail is a revolutionary solution for modern assembly lines. By integrating advanced motorgear boxes, industrial-reducers, and gear box, this system enhances efficiency, precision, flexibility, and safety. The Robot Walking Rail system reduces maintenance costs and downtime while supporting sustainability goals. Investing in this innovative solution can transform your assembly line, making it more competitive and reliable. For more information on how EVS can help revolutionize your assembly line, visit EVS.