Source: www.sodavision.com

Every year, robots become more advanced and are assigned to perform more complex tasks than before. Unlike human labor, they do not tire and are much faster in their operations. However, as they get incorporated into more industrial processes, there is a growing need to make them safer for factory spaces and more accurate in their operations.

It is from this need to make industrial robots more ‘aware’ that robot vision systems came to be. Which brings forth the question, what are robot vision systems? How do they work and do they really make robots better? Here is an in-depth look into all of that and more.

What is Robot Vision?

Source: www.fanucamerica.com

Robot vision in a layman sense is a concept that seeks to help robots see. It is a system comprising different parts that enable the robot to interpret visual data in its surroundings. These parts include:

Cameras- these are mounted on the robot or in its workspace and act as the ‘eyes’ of the robot.

Special lighting– lighting keeps the work area and or objects that the robot is working on illuminated so that the camera can capture them clearly

Software- this is a computer algorithm on which the whole vision system operates.

How Does Robot Vision Work?

Source: prneswprime

The working of a robot vision system is a series of steps that may seem lengthy but happen within seconds. Every part of the system works in conjunction with the other to make ‘sight’ possible. The steps unfold as follows:

The robot is assigned a task such as assembling micro parts onto a PCB board. To assemble the right part at the right place, it requires high precision and some visual guidance to regulate its movements as needed.

The camera is activated to visualize the work envelope or the position of the part and where it should be placed.

The image captured by the camera is sent to the robot controller which interprets it using the computer algorithm.

From this interpretation, a command signal is relayed from the controller to the assembly robot arm.

The command is a code of instructions on what part the robot arm should follow between collecting the part and where it should place it on the PCB board.

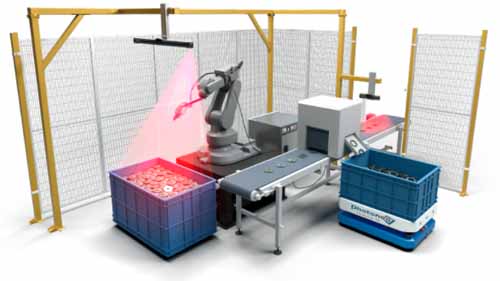

The image captured and relayed by a robot vision system is not just a visual photo. It captures parameters such as the length, width, and height of parts. These details are essential as they help the robot tell different objects apart and also inform how it should position itself as well as the force needed to execute the tasks. Sometimes, for more accuracy, laser triangulation can be used to derive such parameters. It is a more precise method as lasers outline the objects and their sizes can then be picked up by the camera.

3D vision is equally picking up in robot vision systems. While it follows the same vision concept as mentioned above, it delivers more wholesome viewing from different angles. However, in addition to the other parts present in a typical robot vision system, a 3D vision system includes a scanner. It is used to analyze all 3 dimensions of a part or work envelope and trigger the robot to act accordingly. It is more advanced and effective than laser triangulation.

Why Should Manufacturers Use Robot Vision Systems?

Source: www.educba.com

The average robot can be programmed to execute tasks quite effectively with minimal supervision. This has, in fact, been the case in most factories for a while now. So, you may be wondering, is it necessary for you to integrate robot vision systems into your robots? Does it add any value to your robot operations? The brief answer to that is, yes. Here are some of the ways your industrial robots would be improved by robot vision systems.

Accuracy – consider how well you would execute a task blindfolded vs how you would perform with full vision. The latter is better, isn’t it? This too applies to robots. While they can rely on sensors to perform tasks, a vision system makes them way more accurate in how they handle parts and work on them.

Safety– visual capabilities has been found to be highly effective in making robots safer for humans to work with. The combination of a robotic vision system and safety sensors provides double assurance that the robot will halt or slow down when it senses and sees an obstacle in its path.

Higher operational efficiencies when a robot is fitted with a robot vision system, it is more adaptive. Take, for instance, a delta robot tasked with sorting objects rolling on a conveyor belt. Its vision system would perceive the objects and the rate at which they are passing through the system. As the controller interprets such visual data, it would signal the robot arms to work at a speed that matches that of the convert belt. There would be no need to start and stop the belt for the robot to keep up and this improves efficiency.

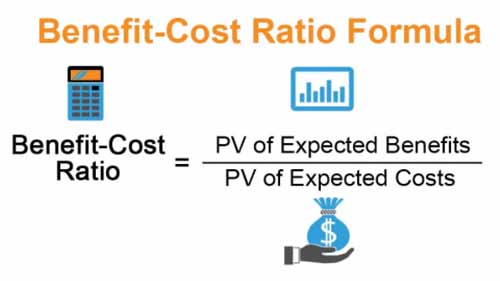

Improved cost efficiency– when operational efficiencies improve, costs of operation also go down. Additionally, decreased need for supervision and lesser need for extra inputs like positioning pallets to support robot accuracy all cut down on extra costs.

Higher value- robots that have robotic vision systems can do more which gives you more value out of the robot. Whereas you may have used a SCARA robot to only assemble parts a vision system can be configured to perform quality inspection after the assembly.

Robot Vision Applications

Source: www.vision-systems.com

Examples of industrial application of robot vision systems include:

Automated warehouses- automated warehouse robots fitted with robotic vision systems are used to collect and deliver packages from various parts of a warehouse to staff. The vision systems eliminate the need for warehouse owners to chart out specific paths for the robots. It helps mitigate costs of automation and makes the robot more flexible in its operations.

Sorting- sorting goods in a manufacturing line is made more accurate and efficient when robots can identify unique products using a visible system. It also makes them faster and reduces wastage and errors that often occur when a robot is working ‘blind’.

Pick and place, Palletizing– being able to see parts and adjust their position accordingly makes robots execute palletizing and pick and place tasks better. The vision system also eliminates the need for additional support systems like positioning pallets.

Automated pharmacies- robotic systems fitted with vision systems are now being used to dispense prescriptions in auto pharmacies. The vision system captures the prescription, sends the image to the controller which then moves a prescription cup to the corresponding dispenser of the requested pill. It is fast, economical and very precise.

Material inspections- this works especially well where the robot vision system has a scanner as it scans each product to detect flaws. This makes quality inspection faster and accurate as such scanning can detect flaws that the human eye could easily miss out on.

Factors to Consider When Investing in Robot Vision System

Source: Pixabay

The concept of a robot vision is largely the same but it would be essential to seek out a reliable service provider. Consider that this is a new concept that may need to be customized for your robots and entire factory setup. Further, your staff may need some orientation to adapt to this mode of robot operation. A robot vision system company that can help you make this transition smoothly would be a plus.

Additionally, weigh the industrial applications you intend to incorporate the robot vision systems for as you choose between options like 3D and others. If the operations are complex then perhaps you would need such extensive vision systems. However, for basic operations like pick and place, a complex vision system would be underutilized and therefore, cost-inefficient.

On compatibility, be sure to consult the robot vision system firm on whether your factory space would be compatible with a vision system. This would especially be of concern if the cameras are to be mounted within the work envelope as opposed to on the robot structure. It may not necessarily make your factory ineligible for the system but you may have to rearrange the space and adjust the lighting.

Challenges of Robotic Vision Systems

Source: Pixabay

Investing in robotic vision systems is an expensive venture. Given as the systems are relatively new in the market, a quality one could set you back a significant amount of money. This is in addition to the costs of maintenance as well as some structural changes that you may have to make in your factory space. This is a challenge that often makes such systems inaccessible to manufacturers operating within budgetary constraints.

Programming robot vision systems can also be quite complex. They are not a plug-and-play solution. In the event that your service provider is not keen on after-sale service, you may need to hire experts to get your system running as it should. On top of this, there will be an adjustment period as the robots begin to operate a bit differently than before once the vision system is installed. Some production downtimes are to be expected before the whole setup begins to run efficiently.

Conclusion

Robots are made in the likeness of human beings. It is thus only natural that they have come full circle and become capable of uniquely identifying and interpreting visual data. As a manufacturer, this would be a value-adding investment in your industrial operations. However, a robot vision system is also only as effective as the robots you have. If you are making the switch to robotic automation, begin by engaging the right industrial robot manufacturer before moving on to robotic vision systems.