Introduction

The domain of manufacturing has experienced a paradigm shift, primarily propelled by the incorporation of robotic systems. One of the most notable developments is the introduction of polishing robots, which have revolutionized the criteria for accuracy and effectiveness in surface treatment procedures. Such innovation is exemplified by the “QJR20-1600 20kg Payload 1668mm Reaching Distance Robotic Arm.” This particular robot distinguishes itself as the initial nationally certified spraying robot available with an explosion-proof capability. It is engineered to execute an extensive range of operations, including palletizing, handling, loading and offloading, laser cutting, spraying, and most significantly, polishing.

The Development of Robotics in Production

Although robotics in manufacturing are not a novel concept, their contemporary roles in the industry are unprecedented in their scope and complexity. During the course of history, robots were predominantly employed for mundane, repetitive duties that demanded minimal skill. Presently, they are essential for the implementation of assignments that demand exceptional accuracy and reliability. A precipitous rise in the implementation of robotics in manufacturing has been enabled by significant technological advancements that have refined, cost-effective, and adaptable robots. Growing numbers of organizations are adopting mechanical assistants as a means to enhance efficiency and reduce the likelihood of human error.

Developments in Automated Polishing

Polishing robots constitute an innovative and revolutionary advancement within the realm of manufacturing. The purpose of these machines is to perform complex surface finishing duties that demand exactness and consistency, both of which are challenging to attain through manual means. Polishing robots have undergone significant technological progress due to the incorporation of sophisticated vision systems, precise motion control, and advanced programming capabilities that enable the robots to conform to various surface geometries and materials. In addition to considerably improving the quality of the finish, the implementation of polishing robots substantially increases the polishing process’s velocity and security.

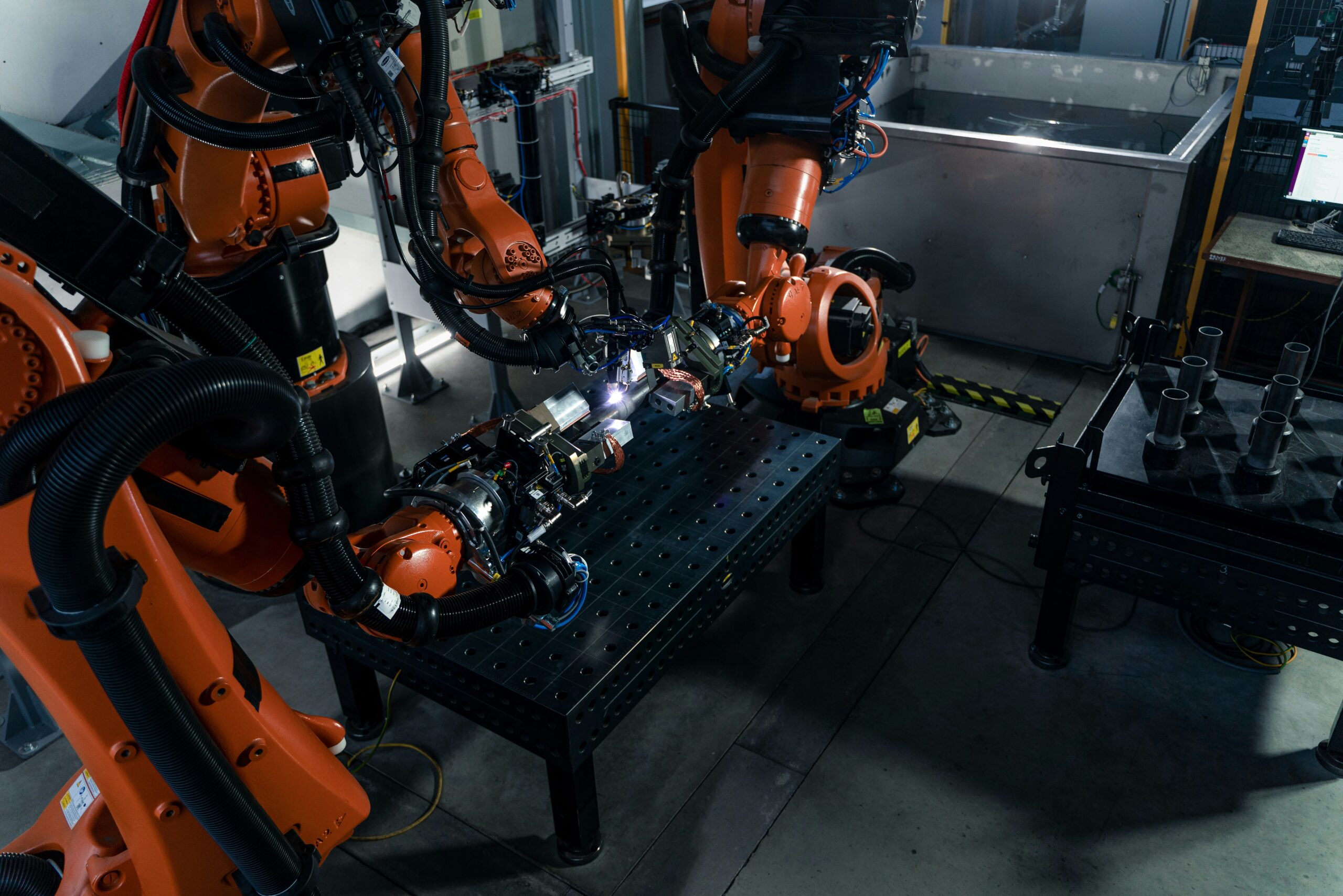

Case Study: Robotic Arm QJR20-1600

When the capabilities of the QJR20-1600 robotic arm are examined in greater detail, it becomes clear why it is considered a revolutionary advancement in robotics in manufacturing. With dimensions of 1668mm in reach, 20kg in maximal payload capacity, and ±0.05mm in repeat positioning accuracy, the robotic arm in question possesses the aforementioned qualities. The aforementioned attributes render it exceptionally suitable for a wide range of applications, including the complex and demanding process of refining. For duties requiring high levels of consistency and precision, the robot’s rapidity of movement and repeatability of position are indispensable. Furthermore, the inclusion of an explosion-proof variant of the QJR20-1600 guarantees its secure operation in flammable material environments, representing a substantial progression in operational safety within manufacturing settings.

Safety Implications and Industry Standards

The advent of robotic systems such as the QJR20-1600 has established novel standards in the realms of manufacturing safety and productivity. This robot’s explosion-proof capability is crucial because it enables secure operation in potentially hazardous environments, thereby reducing the likelihood of accidents by a substantial margin. Further, the adherence to stringent industrial regulations and the maintenance of superior quality standards are facilitated by the accuracy and dependability of robotics in manufacturing. These advancements in quality and safety standards are revolutionizing manufacturing processes, rendering them more efficient and secure than ever before.

Qianjiang QJRB20-1 Robot Case Study

An additional noteworthy prototype, the Qianjiang QJRB20-1 robot, employs cutting-edge “teaching-free technology” to enable autonomous digital production and facilitate rapid changes in production lines. The utilization of this robotic system in the manufacturing process of stainless steel cookware results in notable improvements in both efficiency and energy conservation. By integrating energy-efficient servo controllers and frequency converters, the robot is capable of functioning in a low-power standby mode, resulting in a potential 10% reduction in energy consumption. Furthermore, the SCADA system facilitates remote surveillance of the robot’s operational status, maintenance requirements, and software updates, thereby augmenting overall operational effectiveness.

Conclusion

Smarter, safer, and more effective industrial processes are being made possible by the development of robotics in manufacturing, as demonstrated by polishing robots. In addition to improving the production and safety capacities of industries, robots such as the QJR20-1600 are establishing novel benchmarks for forthcoming advancements in the domain. Anticipating the future, the potential for additional robotics technology advancements continues to expand, offering the assurance of even more profound revolutions in manufacturing methodologies. Polishing machines, which possess the capability to execute intricate and critical duties, are spearheading this industrial revolution by meticulously refining the forthcoming landscape of manufacturing.