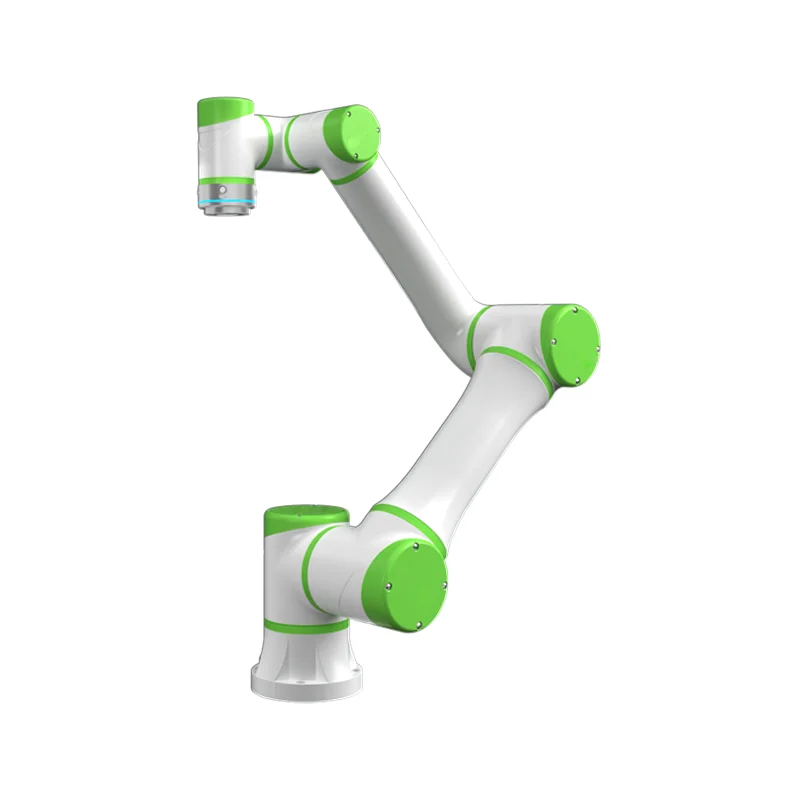

The advent of autonomous systems has instigated a significant revolutionary movement in the continuously developing domain of industrial automation, fundamentally transforming the way responsibilities are carried out in production and manufacturing environments. Six-axis robots and SCARA robots are technologically significant innovations on account of their extraordinary capabilities, high efficiency, and remarkable adaptability. Two robotic systems are thoroughly examined in this article: the “6kg payload 917mm reaching distance 6 axis collaborative robot” and the “3kg payload 400mm 4 Axis Universal SCARA robot EVS3-400.” It sheds light on the advantages and functionalities of these systems in relation to modern industry.

Comprehending SCARA Mechanisms

SCARA robots, denoting Selective Compliance Assembly Robot Arms, are distinguished by their unique limb configuration and highly effective functioning. Automated material handling, assembly, and pick-and-place tasks that require speed and precision, are areas in which these robots excel due to their capability of replicating the motions of a human limb.

A Paragon of Speed and Accuracy: The EVS3-400

In industrial contexts, the “3kg Payload 400mm 4 Axis Universal SCARA robot EVS3-400″ exemplifies the qualities that render SCARA robots indispensable. SCARA robot is an exceptional option for applications in the 3C industries (computer, communication, and consumer electronics), among others, due to its notably low noise, rapid operation, and high transmission accuracy, all of which are facilitated by its compact and flexible design.

The capabilities of the EVS3-400 are underscored by its technical specifications, which include four axes of motion, a maximum reach of 400mm, and payload capacity of up to 3kg. The repeatability of this device is exceptionally high, as evidenced by the repeated positioning accuracy of ±0.01mm along the first and second axes, and the same level of precision in the movements of the third (elevating) and fourth (rotation) axes. The versatility of this SCARA robot extends beyond its speed and accuracy; it can integrate seamlessly with vision systems to improve operational precision.

SCARA Robots’ Positive Aspects in Industrial Automation

SCARA robots, specifically variants such as the EVS3-400, offer a multitude of benefits:

Accuracy and Haste

Their design permits precise, high-velocity motion, which renders them ideal for assembly lines.

Minimal Footprint

SCARA robots are optimal for confined spaces due to their minimal spatial requirements.

Facilitated Integration

Without requiring substantial alterations, they can function in conjunction with humans and other apparatus within established manufacturing configurations.

SCARA robots have brought about a significant transformation in sectors that prioritize velocity, precision, and efficacy by providing a resolution that harmonizes performance and cost-efficiency.

Investigating Six-Axis Robots

Six-axis robots, renowned for their adaptability and range of motion, symbolize an additional pinnacle of robotic innovation. The ability of these robots to manipulate their arms in six distinct orientations empowers them to execute intricate tasks that emulate the dexterity of a human arm, albeit with enhanced strength, endurance, and accuracy.

The 6 Axis Collaborative Robot: An Adaptable Paradigm

“6-axis collaborative robot with 917mm reaching distance and 6kg payload” exemplifies the functionalities that establish six-axis robots as a fundamental element in the field of industrial automation. Designed for many different duties, including palletizing, picking up and placing items, and arc welding, this robot is a workhorse. Its capacity to collaborate closely with human operators increases both safety and efficiency.

Its specifications demonstrate its technical prowess: a payload capacity of 6kg, an armspan of 917mm, and six degrees of freedom to accommodate intricate, multidirectional maneuvers. The capability of the device to perform precise tasks is highlighted by its repeat positioning accuracy of ±0.02mm. Additionally, its broad motion range and speed contribute to operational flexibility. In addition to executing tasks, this six-axis robot assists in optimizing productivity, functioning in confined spaces, integrating into teams, augmenting human capabilities, and protecting against hazardous environments and repetitive labor.

The Advantages Of Six-Axis Robots

Six-axis robots revolutionize industrial processes with their unparalleled adaptability and productivity:

Adaptable Capabilities

Their stamina and range of motion empower them to perform intricate duties, including welding and assembly.

Natural Collaborativeness

These collaborative robots are specifically engineered to improve both safety and productivity.

Sleek and Effective

Six-axis robots, notwithstanding their capabilities, are engineered to function within confined spaces, rendering them well-suited for a diverse range of industrial settings.

Principal Distinction Between SCARA and Six-axis Robots

Business organizations that wish to improve their automation strategies must possess a thorough understanding of the inherent differences between SCARA robots and six-axis robots. Although both categories of robots provide distinct benefits, they diverge in terms of construction, functional scope, and intended use.

Motion Range and Structural Distinction

SCARA robots, such as the “3kg Payload 400mm 4 Axis Universal SCARA robot EVS3-400,” are distinguished by their horizontal arm motions. Their principal applications include material handling, assembly, and pick-and-place. By utilizing a cylindrical coordinate system, their arm is capable of achieving precise placement and rapid operation while maintaining a comparatively compact size.

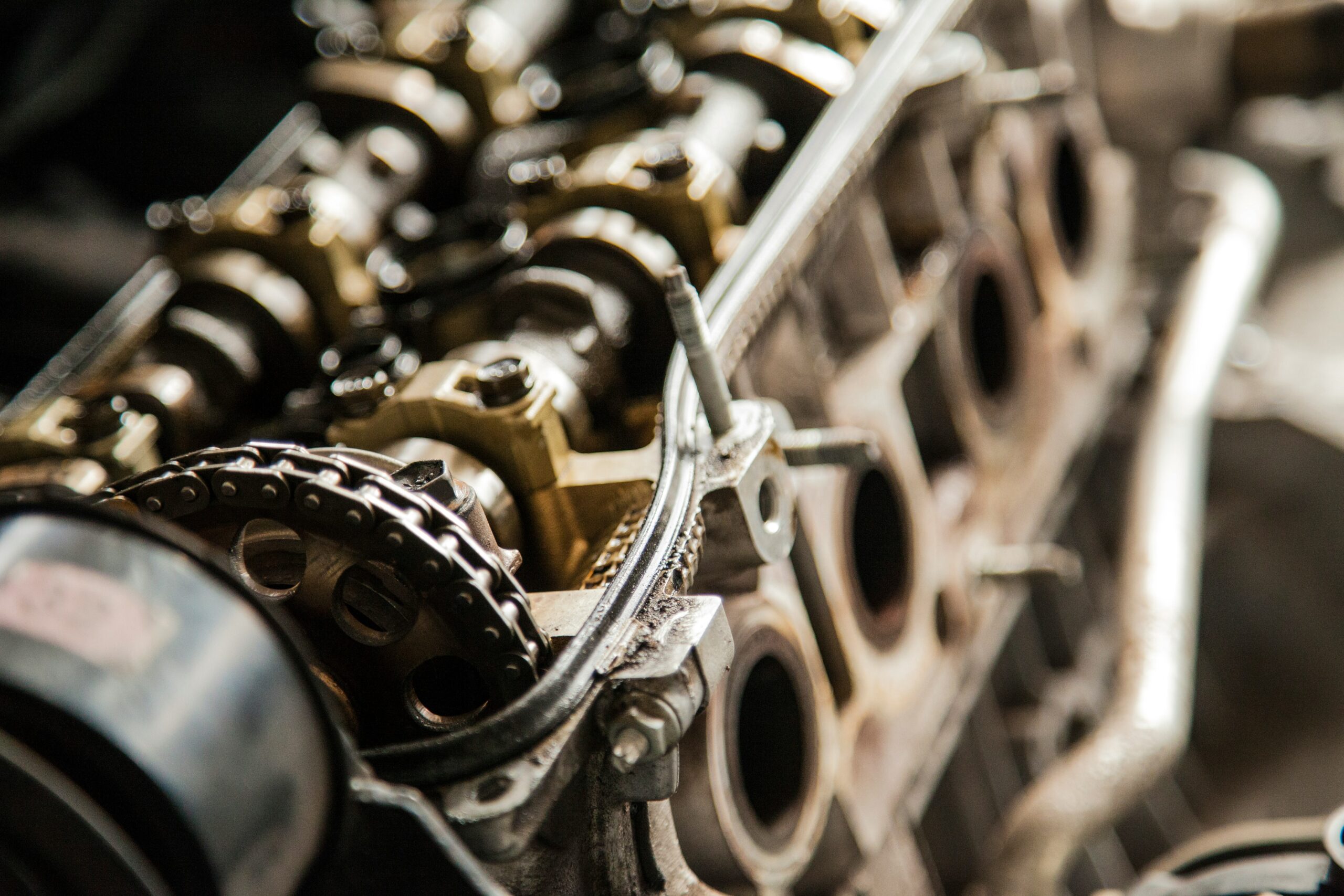

On the contrary, six-axis collaborative robots, such as the “6kg payload 917mm reaching distance 6 axis collaborative robot,” possess six degrees of freedom, which augments their range of motion complexity. This enables them to navigate complex trajectories, perform duties at varying angles, and circumvent obstacles, all of which SCARA robots are incapable of. Versatile in nature, six-axis robots are also capable of handling and assembling components, in addition to welding and machine tending.

Sensationalization of Applications

SCARA Machines

Preferred for applications involving packaging, sorting, and high-speed assembly where speed and accuracy are of the essence, but where the intricacy of motion is comparatively minimal.

Axis Six Robots

Optimal for applications that necessitate intricate manipulations, including arc welding, painting, or procedures that demand access to components from various perspectives.

Practical Implementations

The best way to illustrate the adaptability and capabilities of SCARA and six-axis robotics is by examining their implementations across diverse industries.

SCARA Machines: Accuracy and Rapidity in Assembly

Industries such as electronics fabrication that require rapid and accurate assembly of small components are ideal applications for the EVS3-400 SCARA robot. Space-constrained environments necessitate its use in the assembly of delicate 3C products; its compact stature and accurate motions render it an ideal choice for such tasks.

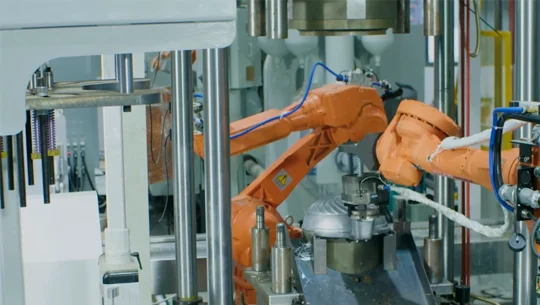

The Adaptability of Six-axis Robots for Complex Tasks

In environments that demand adaptability and collaborative capabilities, such as automotive assembly lines, the six-axis collaborative robot excels. Its versatility and collaborative potential are demonstrated by its capacity to palletize, perform arc welding, and manage tasks frequently in close proximity to human workers; this increases productivity while assuring safety.

SCARA and Six-axis Robots in the Future of Automation

There is an increasing need for robotic systems that demonstrate improved intelligence, adaptability, and efficiency as numerous industries progress. The advancement of robotic technologies, including SCARA and six-axis robotics, will determine the future of industrial automation. Through the implementation of machine learning, artificial intelligence, and sensor technology advancements, this objective will be accomplished.

Emerging Developments and Trends

Integration of AI and machine learning to a greater extent

The augmentation of robots’ autonomy and decision-making capacities facilitates the execution of more intricate and adaptable operations.

Advancement of More Complex Sensor Technologies

Facilitating robots’ comprehension and interaction with their surroundings, thereby enhancing safety and productivity in collaborative environments.

Personalizedization and Adaptability

As organizations strive to develop individualized solutions, the capability of configuring robotics to perform specific tasks will grow in significance.

Conclusion

A comparative analysis of SCARA robots and six-axis robots unveils a multifaceted and specialized industrial automation landscape. The “6kg payload 917mm reaching distance 6 axis collaborative robot” and the “3kg payload 400mm 4 Axis Universal SCARA robot EVS3-400″ serve as prime examples of the capabilities and uses of their respective robot categories. With the continuous progression of technology, the functions of SCARA and six-axis robotics in industrial automation will inevitably expand and transform. This evolution will be propelled by an unwavering commitment to efficiency, adaptability, and novelty. Organizations that remain well-informed regarding these advancements and make strategic investments in autonomous automation can anticipate significant advantages in terms of increased productivity, quality, and competitiveness.

Understanding the distinct functionalities, prospective applications, and distinctive capabilities of SCARA and six-axis robotics will be imperative for manufacturers seeking to maximize the utilization of technology as they navigate the future of industrial automation. The continued integration of robotics into industrial operations will have a profound effect on the development of innovative, safe, and efficient manufacturing processes.