Source: Pixabay

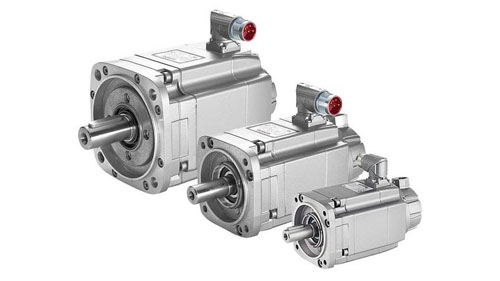

From a distance, a robotic arm may look like a simple appendage that can swing and move from side to side. But the number of parts that are in a single robotic arm will blow your mind. For a robotic arm to be able to function with speed efficiently, it requires all the parts within it to work as designed. Among the many parts that make them up, one of the most important ones is the Servo motors.

We are going to explore what a servo motor is, what it does, the advantages of using them in robotic hands, and their place in the future of automation. If you have been thinking of automating your business and want to know more about servo motors, then you are in the right place.

What is a Servo Motor Arm?

Source: Pinterest

This is a highly advanced robotic arm that is among the most precise robotic machinery that is used to convert rotational motion into linear motion. The efficiency rate is very high, and for that reason, the servo robotic arm is used in applications that require accuracy and precision at all times. The following are the parts that make up a servo motor arm.

- An assembly of electronics that consists of SC and DC electric motors, a potentiometer, and a controller board.

- A case made of plastic housing that accommodates the motor and other important components.

- Several drive gears help regulate the speed of the motors. This is important as it affects how fast the arm can move.

- An output spline is attached to an output shaft as the final interaction point between the object of the motion being created and the servo motor itself.

How a Servo Motor Works

There are many types of servo motors that are used for many works, but the principle behind how they operate is the same the world over. The following are the intricate motions that the motor goes through in executing its functioning.

- It all begins when a signal is sent to the servo from the motion controller.

- The servo then begins rotating a certain amount depending on the pulse width modulation of the signal that has been sent over. When the servo is at rest, the output spline is usually at 0 degrees. This can switch to 90 degrees in one direction when a pulse frequency of 20 milliseconds and a pulse width of 1.5 milliseconds are applied on it.

- The position of the output spline is then monitored closely by the potentiometer. When the desired position is reached, the power supply to the motor is immediately cut, and the servo is forced to hold that position until another signal triggering another command is sent.

- The servo motor is able to operate as fast as it needs depending on the needs at hand. It can go from 0 degrees to 180 degrees as quickly as needed and back. This flexibility is what makes them the ideal robotic motors to use for most of the advanced machinery today.

Advantages of Using Servo Motor for Robotic Arm

Source: Pinterest

The use of servo motors continues to gain momentum in the manufacturing world. People are turning to them because of a number of benefits that they bring to the table. The following are the advantages of using servo motors for robotic arms.

High Torque Density: Servo motors pack a lot of power and this can be3 seen in their high torque density that makes it possible for them to be used in intensive works that require speed and precision. They come with an underlying strain-wave technology which adds a near-zero backlash that minimizes efficiency losses.

Flexible Movement: Robotic arms that use servo motors usually have about 6 degrees of freedom, which is almost as many as those found in a human arm. They can move a whole 360 degrees in either direction with the same high level of accuracy. It also comes with a number of modular integrations that further increase their flexibility, making them the ideal mechanical parts to have if efficiency is the goal.

High-Precision: As far as accuracy is concerned, the best way to achieve that would be to use robotic arms that use servo motors. The inbuilt actuators rely on feedback from encoders, and they are always on the lookout for the slightest changes in positions so they could readjust in split seconds.

Programmability: Servo motors are more sophisticated than regular motors found in most of the mainstream robotic arms. However, their robotic programming is not that hard. Common programming languages like Java, API, C, and Python can be used to create programs that run the servo motors with ease.

Reliability and Durability: Servo motors are made of high-quality parts that are self-designed and produced. They are able to maintain efficiency throughout their life cycles. At the minimum, you are guaranteed about 35,000 hours, which is more than enough to make up for the initial investments as you will be assured of constant work.

Safety: Servo motors come with actuators that are fitted with overtemperature protection that are based on sensors that are integrated into their cores. Ebe the programming itself comes with a safety protocol that ensures any robotic arm that makes use of this technology has the capabilities to function without endangering the lives of those around them or damaging other machines.

Quiet: Servo motors are well oiled and designed to the point you will barely hear any sound when they are operational. This makes them the best for fast-paced production processes as the silence they bring to the floor allows you to be able to catch on to everything that’s happening around you.

Small: Servo motors are not bulky or heavy; this translates to a small robotic arm that is just as equally effective. For this reason, robotic arms that use servo motors are able be used for delicate operations as they can be moved around easily without breaking anything.

What are Servo Motors Used For?

Source: Pinterest

Servo motors have a wide range of applications, considering how reliable and flexible they are. Their use is gaining traction across all sectors of the manufacturing industries. Some of their notable applications include the following.

In machine tools that depend on high accuracies like robotic welding and robotic painting machines, where uniformity is very important.

In robotic applications that require power, accuracy, and speed. They are lightweight, fast, and small in size, perfect for a fast-paced manufacturing environment.

In conveyor and handling systems require consistency, speed, and precision to ensure goods and raw materials are delivered to their respective production stations without fail.

In antenna positioning systems that require high torque and accuracy.

In simulation applications that depend on speed and smoothness on top of the ability to stop at a moment’s notice.

In renewable energy applications require high performance, functionality, and efficiency without any room for errors.

In the modern printing press where accuracy is important, and speed is needed for rapid assembly and production.

In the food and beverage industries that need high caliber servo motors that are able to deal with temperature fluctuations and washdowns.

In defense applications in the military that depend on shock loads and varying temperature ranges for the best performances of weapons and other machines.

In oil exploration in the sea that deals with high pressure and temperatures. Servo motors have the explosion-proof features needed for this kind of intensive and high-risk work to be done.

The Future of Servo Motor Arm

Source: Pinterest

The servo motor can well be described to be one of the most innovative pieces of machinery to come out of the automation era, and as time continues to pass by, better versions of it that have more capabilities will continue coming out. The future is full of all possibilities, and the servo motor can find itself at the center of every robotic technology out there.

By powering the most advanced robotics right now, the servo motor is already achieving more than what its predecessors were able to achieve in the past. As humanity continues to demand more of the technology, the servo motor is best suited to ensure that these demands are fully met in the future.

It will be possible to equip amputees with highly functioning limbs that operate in the same way as real ones. Robotic arms running on servo motors will also have the capacity to conduct delicate operations like surgery or be used in volatile and dangerous environments like sea drilling, exploration of caves, among other important occupations. It is hard to paint a clear picture of what will happen in the next ten years since the pace of development is so fast, but what is clear is that servo motors will be at the center of innovation in the near future.

Conclusion

The importance of servo motors in automation is immense, and that will continue growing as time goes by. Every automated process in the world has some form of the servo motor to technology in use. There are many variants of the servo motor depending on the manufacturing needs, but the working principle is similar underneath them all. For more detailed information on servo motors and robotic arms, check your website at your own time, and we will be there to take on any questions you may have.