Introduction

Fast technical advancements have brought about significant changes in the logistics sector. Precision and efficiency in material handling are being revolutionised by automation, which is at the forefront of innovation in our day. Palletizing robots are one of the biggest innovations; they are revolutionising the field of logistics. Not only are these robots improving operational capacities, but they are completely changing the field of smart logistics as we know it today. We will examine how robotic solutions are improving logistics operations by making them faster, smarter, and overall better as we dig deeper into this topic.

The Rise of Palletizing Robots

What are Palletizing Robots?

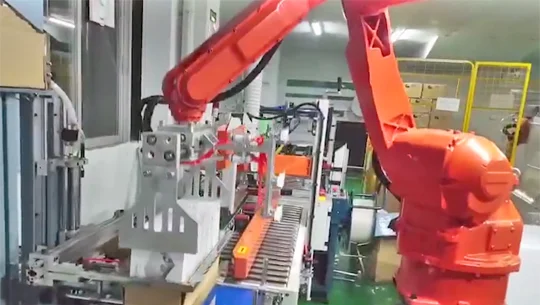

Automating the process of stacking things into pallets is the purpose of palletizing robots, which are robotic equipment. They are a vital component of the mechanics of contemporary logistics. These mechanical marvels have streamlined a task that was formerly labor-intensive and time-consuming. Robots that palletize goods have completely changed the way warehouses operate by lowering personnel costs and increasing output.

The Context of History

The shift from manual to automated palletizing demonstrates the industry’s constant emphasis on transportation efficiency. When palletizing robots were introduced, operations shifted from being human-centric to being technology-driven, marking a significant turning point. In addition to speeding up the palletizing process, this modification decreased the risk of accidents involving the manual handling of large objects.

Technological Developments in Palletizing

Technological developments have been crucial in the field of logistics and material handling, especially with regard to the creation of palletizing robots. Let’s examine two innovative goods that best represent these developments.

180kg Payload 3153mm Reaching Distance Robotic Arm QJRB180-1

The robotic arm QJRB180-1 is a major advancement in palletizing technology. With a remarkable arm span of 3153mm and a 180kg payload capacity, this robot is built for quick and steady operation. For industries that require accuracy and productivity, such as furniture, food and beverage, and 3C (computers, communications, and consumer electronics), this is the ideal solution. The robot’s ±0.5mm repeat positioning precision guarantees precise placement, which is essential in sensitive tasks. This palletizing robot‘s technological prowess positions it as a key component of contemporary smart logistics, streamlining procedures that were previously constrained by human constraints.

800kg Payload 3159mm Reaching Distance Robotic Arm QJRB800-1

The QJRB800-1 robotic arm is built for heavy-duty palletizing jobs and has a larger capacity. With a strong 800 kg payload capacity and an arm reach of 3159 mm, it is an incredible load bearer. This palletizing robot‘s accuracy and dexterity, coupled with its huge capacity, usher in a new age in logistics by making even the heaviest products easy to transport. These days, applications in harsher settings, like brick factories, are less labor-intensive and more efficient because of sophisticated palletizing technology.

These goods highlight the importance of palletizing robots in improving smart logistics operations in addition to showcasing robotic technology breakthroughs. In the logistics industry, these robots offer unparalleled precision and efficiency by automating jobs that were previously done by hand.

Enhancing Smart Logistics with Robotics

Modern supply chain management is centred on smart logistics, a concept that encompasses the integration of cutting-edge technologies into logistics operations. Palletizing robots are an essential component of this integration, pushing the boundaries of precision and efficiency.

The Role of Palletizing Robots in Smart Logistics

Palletizing robots are sophisticated devices that can adjust to a variety of operating requirements; they are more than just mechanical arms. These robots increase overall workflow productivity, minimise errors, and streamline procedures in smart logistics. Palletizing robots‘ smooth integration into logistics systems is an example of how automation can improve operational capabilities by accelerating and enhancing the reliability of procedures.

Robotics and Logistics Systems Working Together

Palletizing robots reach their full potential when they function in unison with the larger smart logistics network. Real-time data exchange, predictive analytics, and flexible responses to shifting demands are made possible by this synergy. As a result, there is a logistics network that is resilient, responsive to market conditions, and efficient.

Examples from the Real World and Case Studies

Palletizing robots‘ real-world uses in logistics provide an insight into their revolutionary potential. These two case studies demonstrate their effectiveness and adaptability.

Case Study 1: Water Dispenser Packing Production Line

A 180 kg payload palletizing robot—the QJRB180-1 type, to be exact—was recently incorporated into a water dispenser packing production line. The entire packing and palletizing process was transformed by this robotic arm when it was used in conjunction with a vision system. The robot managed the pallets for packing as well as the water dispensers thanks to its specifically made grippers. The packing line’s efficiency was increased and labour expenses were significantly reduced as a result of this automation. It’s an effective illustration of how palletizing robots can be tailored to certain industrial requirements and play a critical role in smart logistics solutions.

Case Study 2: Palletizing Pot Cartons

Palletizing pot cartons is another use for the QJRB180-1 palletizing robot. The robot effectively met the requirements of this situation, which included precision and continuous operation. It was capable of carrying out high-speed, high-precision activities like palletizing, picking, packing, and loading because to its 180 kg payload and 3153.7 mm arm span. Palletizing robots are a great way to automate tasks that would otherwise take human labourers to a higher level of fatigue and consistency. They work well with smart logistics systems. This technology has been particularly beneficial to the furniture, food and beverage, and 3C industries, which have seen increases in production and decreases in operating expenses.

Palletizing Robots’ Future in Logistics

Palletizing robots will play an increasingly important role in logistics as we move forward. Even more complex and adaptable palletizing technologies will become available as robotics and artificial intelligence continue to progress.

Predictions and Trends

Palletizing robots are predicted to get more cooperative, perceptive, and adaptive in the future. Advanced sensors, decision-making AI, and improved connection with other smart logistics systems are anticipated features of these robots. These robots will be able to adjust to changing conditions and demands in real-time by integrating machine learning algorithms into their operations.

Innovations on the Horizon

Horizontal innovations in palletizing robot technology could include longer reach, more precision, and higher payload capacity. Furthermore, improving the usability and integration of human-robot interfaces into current logistical systems would be made easier. More human-robot cooperation, where the two work side by side to complement one another’s skills, may also be possible in the future.

In summary

Palletizing robots have revolutionised the handling and transportation of commodities, becoming an essential component of contemporary logistics. Not only have processes been optimised, but their integration into smart logistics systems has created new opportunities for efficiency and creativity. Palletizing robots will surely be a major factor in reshaping logistics in the future and making it faster, more efficient, and smarter as technology develops. Visit EVS Int for more information.

Arabic

Arabic Bulgarian

Bulgarian Czech

Czech Dutch

Dutch English

English Finnish

Finnish French

French Georgian

Georgian German

German Greek

Greek Hungarian

Hungarian Italian

Italian Japanese

Japanese Korean

Korean Lithuanian

Lithuanian Myanmar (Burmese)

Myanmar (Burmese) Persian

Persian Polish

Polish Portuguese

Portuguese Romanian

Romanian Russian

Russian Serbian

Serbian Slovak

Slovak Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese