The integration of gear boxes with welding positioners in contemporary production greatly improves automation, accuracy, and productivity. While the gear box maximizes speed and torque control, welding positioners are essential parts that rotate and keep workpieces in place throughout the welding process. The Single-Axis Head and Tail Stock Positioner and the Two-Axis Servo Positioner are two examples of the sophisticated welding positioners and precision-engineered gear boxes that EVS offers. These devices are made to increase overall productivity and guarantee perfect welding outcomes.

Recognizing Welding positioners’ Function

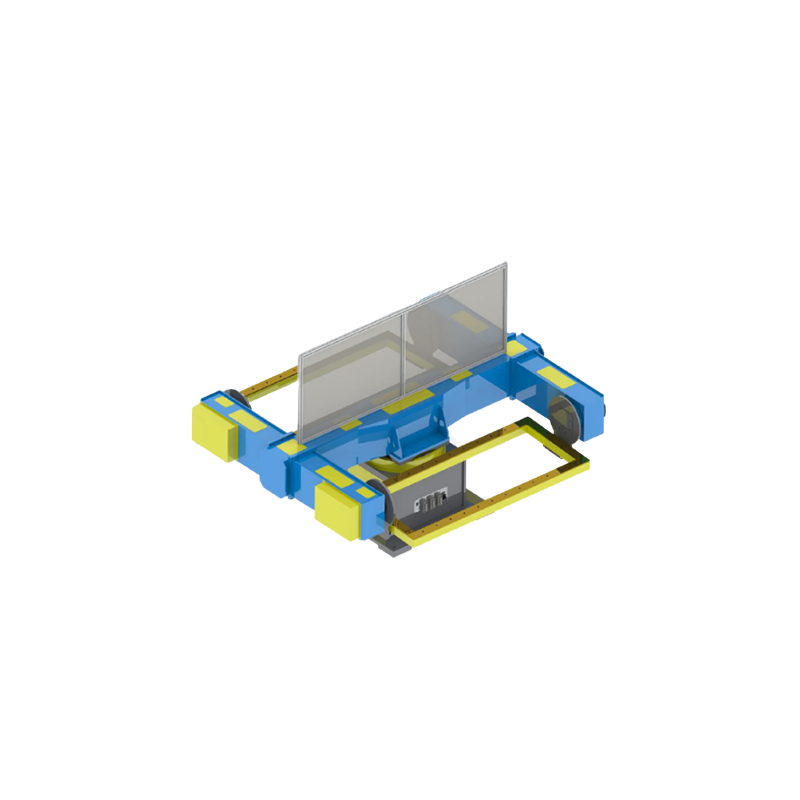

Welding positioners are crucial for increasing welding precision because they provide steady workpiece rotation and positioning, enabling welding robots to carry out their duties with ease. These welding positioners‘ incorporation of a gear box enables more precise and regulated motions, guaranteeing precision throughout the welding process. Large-scale welding operations where accuracy is crucial will benefit greatly from the steady and smooth rotation that the EVS Single-Axis Head and Tail Stock Positioner offers for heavy workpieces.

Manufacturers may automate the movement of workpieces and free up welding robots to perform intricate and accurate welds without interruption by combining welding positioners with gear boxes. Even for difficult geometries, this combination guarantees high-quality welds and helps minimize mistakes.

Increasing Output with Gear box Integration

Because a gear box gives welding positioners exact control over torque and speed, it has a direct influence on productivity. Workpieces are precisely turned by welding positioners with high-quality gear boxes, enabling welding robots to produce continuous, uninterrupted welds. With dual-axis mobility provided by the EVS Two-Axis Servo Positioner, the welding robot can access regions that are difficult to reach with greater flexibility, leading to shorter production cycles.

By lessening system wear and tear, gear boxes also add to the welding positioners‘ lifetime and durability. Manufacturers may minimize downtime, boost throughput, and improve overall operational efficiency in their manufacturing lines as a result of this enhanced efficiency.

Enhancing Adaptability in Applications of Welding

Welding processes become more versatile when gear boxes and welding positioners are used together, which facilitates handling a range of workpieces and welding procedures. Welding positioners make sure that every component, no matter how little or huge, is precisely positioned so that welding robots may operate with accuracy. Large, cylindrical items work well with the Single-Axis Head and Tail Stock Positioner, while multi-sided welding applications benefit from the more sophisticated movement capabilities of the Two-Axis Servo Positioner.

These welding positioners‘ gear boxes enable producers to readily modify the speed and torque needed for various jobs, enabling fluid and adaptable operation. Because of its adaptability, businesses may swiftly adjust to changing welding needs without compromising on productivity or quality.

Increasing Welding Precision and Decreased Errors

The increased precision in welding processes is one of the main benefits of integrating welding positioners with a gear box. The welding positioners may move smoothly and at a constant pace thanks to a gear box, which guarantees that every weld is done precisely. When paired with a gear box, EVS’s Two-Axis Servo Positioner enables welding robots to precisely access a variety of angles and positions, doing away with the need for manual adjustments.

The use of gear boxes guarantees steady and dependable movement for welding positioners, reducing the possibility of human mistake and enhancing the overall quality of the weld. Because of this exact control, producers can maintain uniform welds and lower the risk of faults and rework, which may save production time and costs.

Cutting Labor Expenses and Boosting Productivity

By limiting manual involvement, automation using welding positioners and gear boxes greatly lowers labor expenses. Welding robots may work constantly because welding positioners with gear boxes automatically manage the movement of the workpiece. Because of this automation, fewer operators are required on the manufacturing floor, freeing up manpower for tasks that need more skill and value.

Welding positioners and gear boxes increase operational efficiency by lowering human error and increasing welding efficiency. For enterprises wishing to expand, the simplified manufacturing process is an affordable investment since it allows them to fulfill increased demand without sacrificing the quality of their welds.

In conclusion, Welding Automation’s Future

In contemporary welding processes, the combination of gear boxes with welding positioners provides unmatched precision, flexibility, and efficiency. The Single-Axis Head and Tail Stock Positioner and the Two-Axis Servo Positioner, two of EVS’s sophisticated welding positioners, demonstrate how a well-designed gear box can improve efficiency and output. This integration assists producers in producing welds of superior quality, lowering mistake rates, and increasing overall productivity by automating workpiece movement and guaranteeing exact control.

Businesses trying to compete in the fast-paced industrial environment of today must invest in welding positioners with gear boxes. Welding positioners and gear boxes will play an increasingly essential role in optimizing production as the need for automation grows.