Introduction

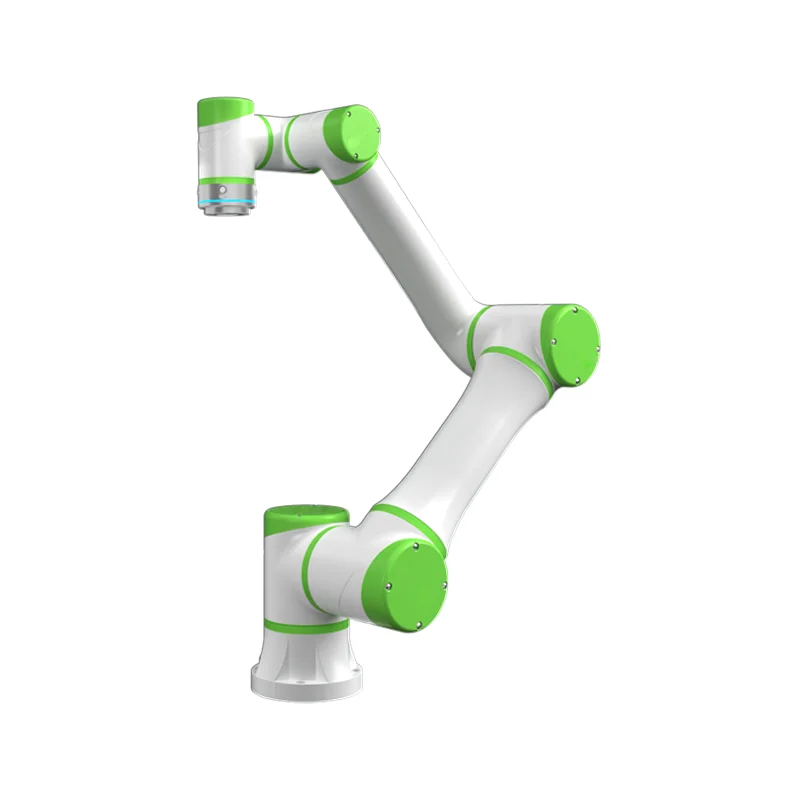

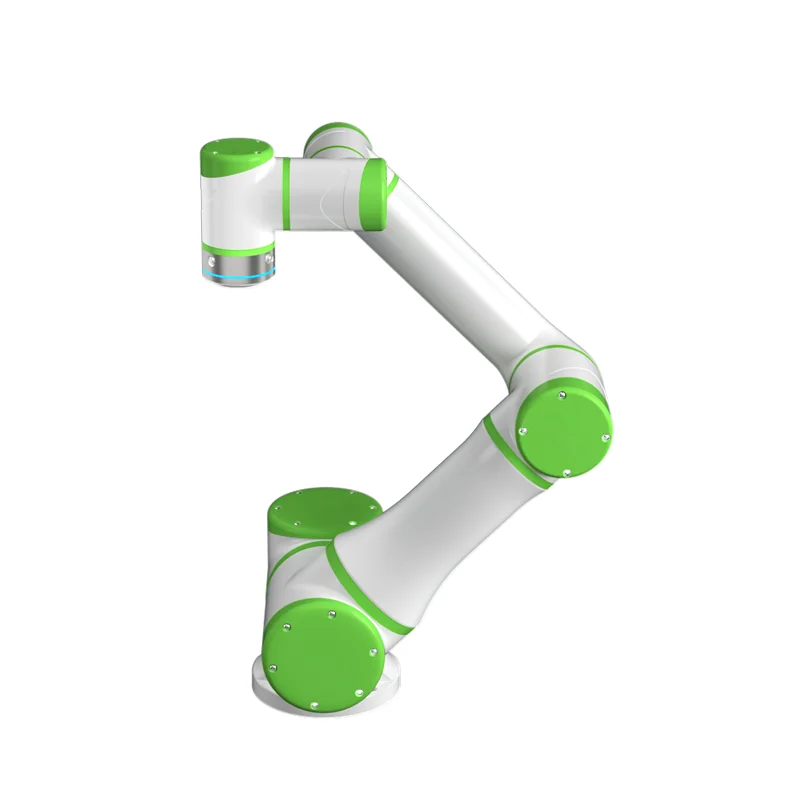

Since the inception of technology, there have been significant transformations in the production, distribution, and utilisation of products. In particular, the implementation of six-axis industrial robotics is to blame for this revolution in automation. An essential component of the swiftly developing domain of robotics in logistics, this essay explores the realm of six-axis robots. These machines are essential in contemporary e-commerce fulfilment centres, where accuracy, velocity, and effectiveness are of the utmost importance. They are not merely tools. We’ll pay special attention to two devices that serve as examples as we examine their features and advantages: a 6 kilogramme payload robot with a 917 mm reach and a 12 kg payload robot with a 1300 mm reach. Both perfectly capture the sophisticated capacities and versatility of six-axis robots in logistical processes.

The Emergence of Six-Axis Robots in Logistics

Robotic arms with six degrees of freedom, or the ability to move and rotate in six different ways, are referred to as “six-axis robots“. Because of their adaptability, they are exceptionally well-suited for complex tasks in a variety of industries, particularly logistics. Six-axis robots provide exceptional manoeuvrability and adaptability within e-commerce fulfilment centres, which frequently engage in the classification and manipulation of an extensive range of products. Our two products exemplify the increasing utilisation of these robots in the logistics industry to perform tasks that were previously labor-intensive and susceptible to error. Applications for them include picking, packing, and sorting as well as more difficult jobs like assembly and quality assurance. Six-axis robots are a great way to increase productivity in logistics while also guaranteeing uniformity and dependability, which are critical in the quick-paced world of online shopping.

Operational Advantages in E-commerce Fulfillment Centers

Six-axis robots have many advantages in terms of operations, especially in the busy e-commerce fulfilment centres. Perhaps the best example of their impact comes from a case study with the QJR10-1 model. The efficiency of six-axis robotics in logistics is exemplified by this robot, which has a 10 kg payload and an arm span of 1671 mm.

Increased Flexibility and Effectiveness

Like many other six-axis robots, the QJR10-1 is capable of a wide range of operations, including feeding workpieces, selecting completed goods, and cutting extra material. Because of its adaptability, a single robot may manage several stages of the logistics industry, simplifying processes and lowering the requirement for specialised equipment.

Flexibility in Production

It’s revolutionary because six-axis robots can adjust to accommodate various product models on the same assembly line. This adaptability greatly increases throughput while also saving time when rearranging the production line for various goods.

Labour Optimisation

Human labour can be diverted to more skill-intensive fields while robots take over physically taxing and repetitive jobs. In addition to raising overall productivity, this also raises job satisfaction and worker safety.

Technical Capabilities of Six-Axis Robots

The technical prowess of six-axis robots lies in their six distinct axes of movement, each contributing to their unparalleled flexibility and precision. Let’s break down these axes, using our product examples for illustration:

Body Rotation Axis (Joint 1)

Enables the robot to rotate its base, providing a comprehensive range of motion.

Front and Rear Swing Axis of the Main Arm (Joint 2)

This axis allows the robot to extend or retract its arm, crucial for tasks like palletizing or pick-and-place.

Front and Rear Swing Axis (Joint 3)

Further extends the reach and flexibility of the arm, especially useful in tight spaces.

Circular Tube Axis (Joint 4)

Enhances the robot’s ability to orient objects, vital for precise tasks such as assembly.

Wrist Axis (Joint 5)

This axis mimics the movement of a human wrist, adding to the dexterity of the robot.

End Rotation Axis (Joint 6)

The final axis, allowing for the precise orientation of the tool or gripper.

These axes, combined with high-speed motion and repeat positioning accuracy of ±0.02mm, as seen in our product examples, make six-axis robots incredibly effective in logistics operations.

Integration and Collaboration in the Warehouse Environment

Six-axis robot integration in a warehouse setting involves more than just installation. These robots are made to work in unison with human employees, increasing productivity while upholding safety regulations. This collaborative quality is especially noticeable when it comes to our payload robots, which weigh 6 kg and 12 kg. They can operate in small locations and have a compact structure, so they don’t significantly affect current procedures. These robots’ collaborative nature also means that they can operate alongside people without the need for substantial safety barriers, which maximises available space and boosts productivity.

Comparing Six-Axis Robots to Other Robotic Solutions

While there are many different robotic options for manufacturing and logistics, six-axis robots provide a number of advantages over four-axis robots.

Increased Range of Motion

Six-axis robots can perform jobs requiring more flexibility and dexterity because of their wider range of motion.

Managing Complex Tasks

Their versatility in rotating and arranging objects in various orientations makes them perfect for intricate jobs that four-axis robots could find difficult to do.

Economic Impact and ROI

The deployment of six-axis robots, such the ones mentioned above, might significantly affect e-commerce fulfilment centres’ financial situation. The long-term return on investment (ROI) is significant, even though the initial investment may be large. These robots minimise downtime, lower error rates, and improve operational efficiency. These elements eventually lead to lower operating costs and higher productivity, which makes the original investment justified.

Challenges and Considerations

Six-axis robots have several benefits, but there are drawbacks to their use as well:

Excessive outlay at first

Purchasing and setting up six-axis robots might have significant upfront costs.

Technical specifications

It’s critical to guarantee that these robots can be operated and maintained by qualified individuals and the proper infrastructure.

Staff training and gradual implementation are two strategies to help reduce these difficulties.

Future Trends in Robotics and Logistics

Exciting breakthroughs are ahead for robotics in logistics. More autonomy and efficiency from six-axis robots is anticipated as AI and machine learning continue to progress. Their importance in e-commerce logistics will be further cemented by this progression, which will also test the limits of what fulfilment centres can accomplish.

Conclusion

The e-commerce fulfilment centre landscape is being redefined by six-axis robots. Through increased effectiveness, adaptability, and accuracy, they provide observable advantages that result in financial profits. Their use of robotics in logistics is only going to increase as technology develops, ushering in a new era of industrial automation. Visit EVS Int for more information.