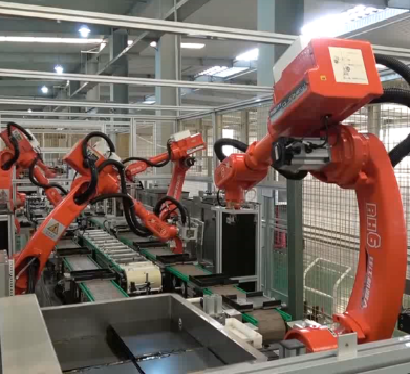

Pick and place robots and polishing robots are critical for automating repetitive activities and increasing productivity in today’s competitive production environment. Modern robotic systems, such as the QJRB15-1 and QJRB30-1 from EVS, are made to fulfill these industrial demands. These robots’ accuracy and adaptability help production lines run more smoothly and consistently by optimizing them. In contemporary production settings, pick and place robots and polishing robots are essential because they simplify procedures, lower labor costs, and enhance overall product quality.

Pick and place robots’ Place in Automation

One excellent example of a pick and place robot is the EVS QJRB15-1. Suitable for a range of industries, its 15kg payload and 1510mm reach enable it to handle light to medium-weight goods. This minimizes human mistake and lessens the demand for physical effort. Manufacturers may improve product quality, save operating costs, and boost productivity by incorporating pick and place robots like the QJRB15-1. Furthermore, by picking and placing objects in precise placements, the robot’s precision motion skills increase manufacturing line accuracy.

Increasing Production Efficiency using Robots for Polishing

In sectors including consumer goods, aerospace, and automotive where surface finishing and detailing are necessary, polishing robots play a critical role. The QJRB30-1, a high-performance polishing robot from EVS, has an 1820mm reach and can carry a 30kg payload. Because of its ability to handle larger and more substantial materials, this robot can precisely finish even the most intricate polishing operations. By automating surface treatment procedures, polishing robots remove the inconsistent nature of hand polishing.

Smooth and controlled motions are crucial for polishing complicated surfaces, and the QJRB30-1 provides just that. Polishing robots such as the QJRB30-1 minimize cycle times by operating constantly at high speeds in addition to enhancing surface quality. These robots improve uniformity and quality in the production process by guaranteeing a consistent finish on all goods. High-quality surface finishes are achieved while lowering production costs and waste for manufacturers.

Using Pick and place robots to Improve Workflow Integration

By optimizing operations, pick and place robots are integrated into industrial systems, which dramatically increases productivity. When it comes to picking up components, arranging them precisely, and putting them on a manufacturing line, the QJRB15-1 from EVS is very useful. Pick and place robots remove bottlenecks and ensure continuous production flow, whether they are handling tiny electronic components or packaging materials.

Pick and place robots provide uninterrupted operation of production lines by streamlining material handling. By doing this, producers can fulfill deadlines and save downtime. The QJRB15-1 is a great option for automation in sectors like electronics, pharmaceuticals, and food packaging because of its dependability and capacity to do repeated jobs consistently increase production.

Robotic Polishing for Reliable and High-Quality Finishing

Many businesses require a uniform surface quality, and polishing robots offer the accuracy required to achieve these expectations. Because of its high degree of precision in handling polishing duties, the EVS QJRB30-1 can guarantee that surfaces are polished uniformly and to the appropriate texture. By providing consistent finishes, polishing robots in manufacturing enhance a product’s appearance and usefulness.

Manufacturers may ensure uniform product quality by standardizing their finishing operations through the use of polishing robots. The QJRB30-1 ensures uniformly smooth and uniform finishes on a range of surfaces, including metals and plastics. Because of its autonomous and continuous functioning, this robot requires a great deal less manual labor, which increases productivity and lowers operating expenses.

Using Polishing and Pick and place robots to Increase Productivity

Increasing production productivity requires the use of pick and place robots as well as polishing robots. These robots are ideal for a variety of sectors, including electronics and the automotive industry, since they are adaptable, reliable, and efficient. These robots’ flexibility enables them to adjust to various production requirements, improving the scalability of industrial processes. The QJRB15-1 and QJRB30-1’s continuous operation and accurate motions provide long-term cost advantages and efficiency.

In summary

In conclusion, manufacturing lines in a variety of sectors are undergoing a revolution thanks to the combination of polishing robots like the QJRB30-1 and pick and place robots like the EVS QJRB15-1. These robots simplify procedures and cut expenses by offering the precision, quickness, and efficiency required for contemporary production. These pick and place robots increase production while improving product quality by automating labor-intensive and repetitive operations. Modern robotic technology must be integrated into production processes as automation rises in order for businesses to stay competitive in the current industrial environment.