Introduction

Welding technology’s advancement has significantly transformed the manufacturing procedures of numerous industries. The adoption of sophisticated tools and techniques is primarily influenced by three key factors: accuracy, productivity, and uniformity. One notable aspect of these developments is the capacity of welding turntables and laser welding robots to provide welding of exceptional quality and operational efficacy. The present article delves into the interplay and mutual advantages of these technologies.

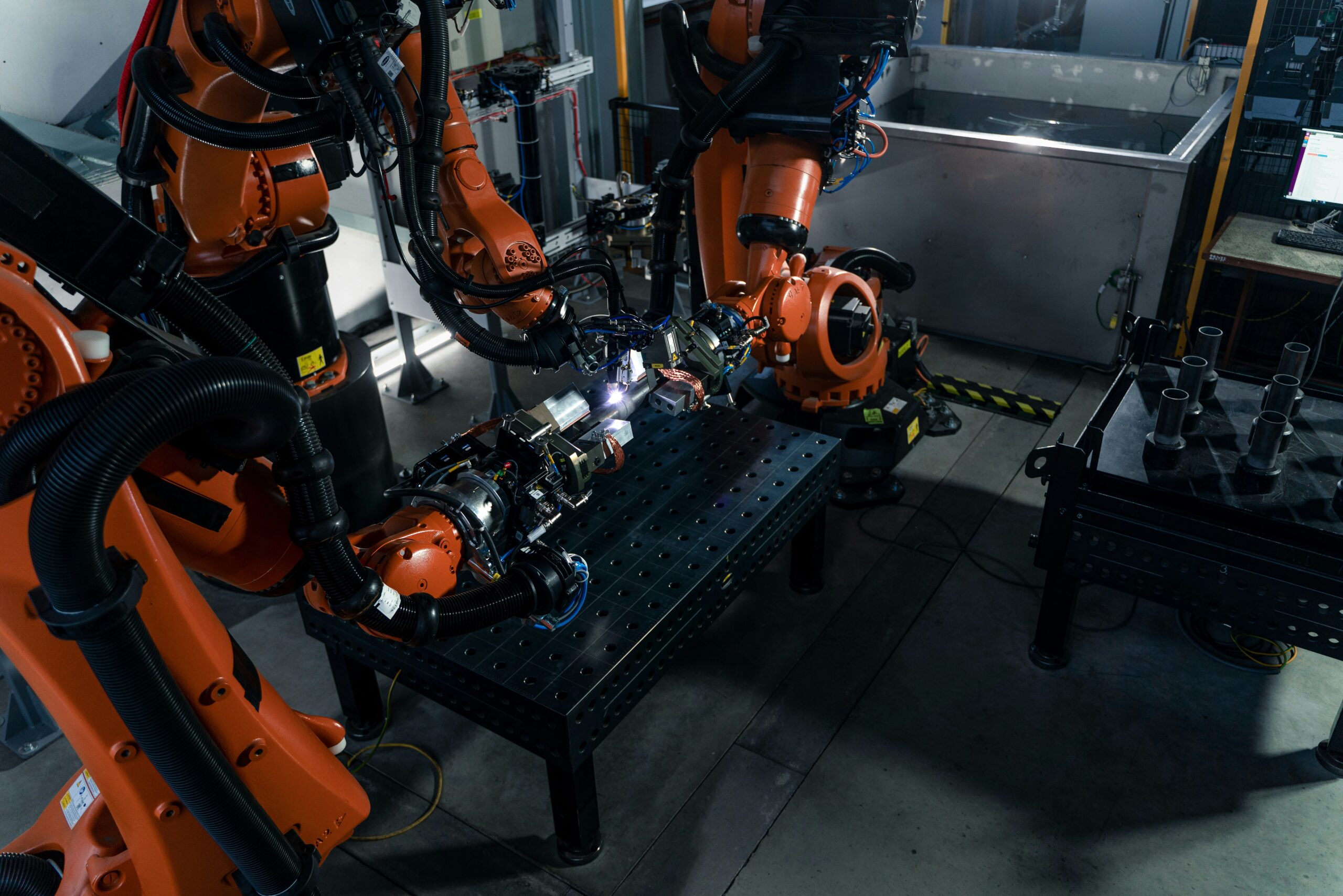

Comprehending Robots for Laser Welding

In the automation of welding, laser welding robots signify a substantial advancement. Welding materials with high precision and velocity, these robots are well-suited for intricate and high-volume welding operations by utilizing laser beams.

Characteristics and Advantages

Sophisticated functionalities optimize the performance of laser welding robots. “6KG Payload 2014mm Reaching Distance 6 Axis Welding Robot QJR6-2000H” is a noteworthy product. Several innovative features are present on this robot:

Mechanism for Adjusting Gear Gaps: This component enhances the precision of the welds by improving joint accuracy.

The flexibility of the welder is increased during welding operations due to the increased joint support stiffness provided by the hollow wrist structure.

The implementation of a noise reduction innovation protected by a patent results in a more tranquil workplace by minimizing operational noise.

By minimizing end clearance, anti-shake optimization increases operational rigidity and decreases control errors.

Qualities of a Technical Nature

Additional capability demonstration is provided by the QJR6-2000H robot’s technical parameters:

The accuracy of the repeated position is 0.08%.

Maximum Length: 2014mm

Metals for the Workplace: carbon steel, stainless steel, aluminum, and copper, among others.

Range of Motion:

J1: ±175º J2: ﹢159º,﹣95º

J3: ﹢95º,﹣125º

J4: ±183º

J5: +129, -126°

J6: ±360º

J1: 189º/s; J2: 189º/s; J3: 189º/s; J4: 378º/s; J5: 320º/s; J6: 687º/s

Modern welding processes can benefit significantly from laser welding robots such as the QJR6-2000H due to these characteristics.

Welding Turntables: An Investigation

Positioners, which are alternative names for welding turntables, are indispensable for improving the precision and speed of welding operations. They ensure holistic welding coverage and accessibility by furnishing a stable platform that permits the rotation of workpieces.

Characteristics and Advantages

The “Single Axis Welding Positioner EVS-SWP-ZW-500/800/1200” is a notable illustration of a welding turntable. Several benefits are associated with this positioner:

The stress relief annealing process is applied to the fixing base, which is constructed from high-quality section material, in order to guarantee correct machining and stable operation.

Case and Tail Case for the Gyration Main Spindle: Made from section material of superior quality, these components guarantee longevity and steadiness.

To weld A stable surface for welding operations is provided by the gyration frame, which is constructed from high-quality section steel. To facilitate the installation of positioning tools, standard pitch tapped holes are utilized.

AC Combining a servo motor with an RV reducer ensures precise positioning and high gyration stability.

Electrical Conductive System: Brass is employed in this system due to its exceptional conductivity, which guarantees both safety and dependability.

Qualities of a Technical Nature

Its capabilities are further underscored by the technical parameters of the EVS-SWP-ZW-500/800/1200:

Repeat Positioning Accuracy:?0.10mm,?0.12mm, and?0.15mm Underrated Load: 500kg, 800kg, and 1200kg

70?/S, 70?/S, 50?/S is the rated speed of gyration.

360 degrees represents the maximum angle of rotation.

In complex projects, these characteristics render welding turntables essential for attaining accurate and uniform welds.

Electromagnetism and Welding Turntables Working in Concert

Welding processes are significantly improved by the potent combination produced by integrating laser welding robots with welding turntables. Increased precision, productivity, and adaptability are a few of the numerous advantages that this synergy provides.

Increased Accuracy and Diminished Inaccuracies

Welds are executed with exceptional precision by virtue of the combination of welding turntables and laser welding robots. When the turntable’s capability to rotate workpieces is combined with the robot’s precision, all sides are welded in a seamless and uniform fashion. Implementing this approach ultimately enhances the quality of the end product by decreasing the probability of errors and rework.

Superior efficiency and productivity

By combining welding turntables with laser welding robots, the welding process is streamlined. By reducing the requirement for manual adjustments, the turntable facilitates uninterrupted welding operations by precisely positioning the workpiece. As a consequence, environments entailing high-volume production benefit from accelerated cycle times and enhanced throughput.

Capability to Resolve Complex Geometries and Diverse Materials

Laser welding turntables and a broad spectrum of materials are amenable to their operation due to their adaptability. The EVS-SWP-ZW-500 turntable can accommodate workpieces of varying sizes and shapes, whereas the QJR6-2000H robot is capable of welding carbon steel, stainless steel, aluminum, and copper. The ability to adapt and function in various sectors renders the integrated system well-suited for a wide range of applications.

Real-World Applications and Case Studies

The convergence of welding turntables and laser welding robots has been effectively implemented across numerous industries. This integration is used, for instance, to precisely weld automobile frames and bodies in the automotive industry. It guarantees critical components’ structural integrity in the aerospace industry. Practical advantages and efficacy of this technology are highlighted in these case studies.

Indicators of Performance and Technical Parameters

To optimize the use of welding turntables and laser welding robots, it is critical to comprehend their technical parameters and performance metrics.

Analytical Comparison in Extensive Detail

Performance is influenced by particular technical parameters of the QJR6-2000H robot and the EVS-SWP-ZW-500/800/1200 turntables. High precision is ensured in welding operations, for instance, by the repeat positioning accuracy of the robot (-0.08mm) and the accuracy of the turntable (-0.10mm to -0.15mm). Furthermore, the turntable’s rated load capacities (500kg, 800kg, 1200kg) and the robot’s maximum armspan of 2014mm demonstrate their efficacy in managing a wide range of workpieces.

Assessing the Velocity, Load Capacity, and Precision of Repeat Positioning

While the load capacity of welding turntables enables them to support heavy and sizable workpieces, the repeat positioning precision of laser welding robots guarantees consistent welds. Maximal downtime and increased productivity are outcomes of welding operations facilitated by the gyration speed of the turntable (70?/S, 50?/S). The integrated system is exceptionally effective due to the fact that these parameters collectively affect the overall quality and efficiency of the welding process.

Advantages of Welding at 360 Degrees

360-degree welding is the sum of numerous advantages that result from the combination of welding turntables and laser welding robots. By implementing this methodology, the welding process is thoroughly inspected and made more accessible.

Accessibility and Comprehensive Coverage

The rotation of workpieces on welding turntables guarantees that all sides are accessible for the welding process. Reducing the likelihood of errors and inconsistencies, this process obviates the necessity for manual repositioning. In whichever orientation the workpiece is, the robot’s accuracy guarantees high-quality, uniform welds.

Manual Interventions Are Decreased

Manual interventions are significantly reduced due to the automation offered by laser welding robots and welding turntables. By doing so, the welding environment is not only made more secure but error by humans is significantly diminished. Enhancing overall efficiency, operators are able to concentrate on supervising the process instead of making manual adjustments.

Enhancement of Weld Quality and Consistency

Every weld is consistent and of superior quality due to the integration of these technologies. The stability of the turntable and the precision of the robot work in tandem to ensure the production of consistent welds, even on complex geometries. This conformity is critical, especially in industries such as automotive and aerospace production, where weld integrity is critical.

Application Examples from the Industry

The combination of welding turntables and laser welding robots guarantees structural integrity and strength during the fabrication of large-scale objects, including wind turbine components. Likewise, this integration lends the precision and effectiveness required to adhere to rigorous quality standards during the fabrication of heavy machinery.

Prospects for Welding Technology in the Future

The continuous advancement of technology augurs positively for the future of welding. Upcoming developments and enhancements in welding turntables and laser welding robots are anticipated to bring about a further revolution in the sector.

Innovative and Awakening Technologies

Laser welding robots that are more precise and adaptable may incorporate artificial intelligence and improved sensors in the future. Material and design advancements that augment the load capacity and stability of welding turntables may constitute improvements.

Laser Weld Robot and Turntable Enhancements That Are Possible

Increased payload capacities, accelerated speeds, and more user-friendly programming interfaces are all potential enhancements to laser welding robots. Proximity to load, seamless integration with other automation systems, and enhanced rotational precision could be the focus of future developments in welding turntables.

Future Development Predictions Regarding Automated Welding Systems

It is anticipated that the integration of intelligent technologies, including machine learning and the Internet of Things, will gain greater prominence in forthcoming automated welding systems. These advancements will enable predictive maintenance and real-time monitoring, which will reduce downtime and increase overall productivity. Due to the unparalleled levels of efficiency and precision they provide, the integration of laser welding robots and welding turntables will continue to be indispensable for this advancement.

In summary

As a result of integrating laser welding robots with welding turntables, numerous advantages accrue, including increased versatility, decreased errors, and improved precision. This fusion is transforming the welding industry as a dependable and efficient solution for high-volume and complex welding tasks. As the technological landscape for welding becomes more and more auspicious, welding turntables and laser welding robots occupy the vanguard.