Introduction

In recent decades, the manufacturing sector has experienced a significant paradigm shift, which can be attributed primarily to advancements in robotics. SCARA machines, an acronym denoting Selective Compliance Assembly Robot Arms, have become indispensable elements in this domain of advancement. SCARA robots, renowned for their exceptional capability in executing rapid select and place operations, have made a substantial impact on enhancing assembly line productivity and accuracy. This article provides an analysis of the evolutionary trajectory of SCARA robotics, delving into their evolution from their initial implementation in assembly lines to their current significance within advanced manufacturing settings. To demonstrate the adaptability and technological prowess that SCARA robots offer to the manufacturing industry, this narrative looks at two exceptional models: the 3kg Payload 400mm 4 Axis Universal SCARA robot EVS3-400 and the 10kg Payload 2001mm Reaching Distance Robotic Arm QJR10-2000.

Understanding of SCARA Robots

SCARA robots, characterized by their unidirectional arm configuration, are purpose-built to perform a diverse range of assembly tasks that require both precision and speed. The introduction of these technologies within the manufacturing industry signified a significant progression in the mechanization of previously arduous, time-consuming, and prone to error responsibilities. The arm’s motion of the SCARA robotics is selectively compliant, which contributes to their exceptional proficiency in ‘pick and place’ operations. Due to this attribute, they have become essential in responsibilities that require accuracy, such as the assembly of electronic components.

SCARA Robots’ Function on Assembly Lines

Since their inception, assembly lines have been the backbone of the manufacturing industry. A paradigm shift occurred when SCARA robots were inaugurated in these environments. As a result of their capacity to execute repetitive duties with precision and velocity, these robotic systems have substantially diminished labor expenses and production durations. The capabilities of SCARA robots on assembly lines are exemplified, for instance, by the 3kg Payload 400mm 4 Axis Universal SCARA robot EVS3-400. Its low noise, compact and flexible design, rapid operation, and precise transmission have all contributed to its widespread adoption in assembly, palletizing, and handling processes. The technical attributes of the EVS3-400, including its maximum reach of 400mm, payload capacity of up to 3kg, and repeated positioning accuracy of ±0.01mm, serve to emphasize the accuracy and productivity that SCARA robots bring to contemporary manufacturing processes.

Advancement to Modern Manufacturing

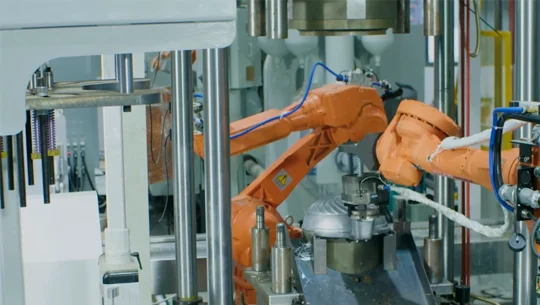

Pick and place robots possess a degree of adaptability that transcends conventional assembly lines and permeates the domain of advanced manufacturing. In this context, they are not solely carrying out predetermined duties; rather, they are integrated with intelligent technologies and vision systems, which empower them to adjust to diverse manufacturing scenarios. The QJR10-2000, a 10kg Payload 2001mm Reaching Distance Robotic Arm, serves as an exemplary illustration of this transition. Its high repeat positioning accuracy, expansive workspace, and rapid operation render it well-suited for a diverse array of tasks, encompassing assembly, welding, spraying, loading and unloading, sorting, and handling. The versatility of this robot is enhanced by the fact that it can be positioned in an inverse position or on the ground. This demonstrates how SCARA robots are advancing to accommodate the varied requirements of sophisticated manufacturing processes.

Case Studies Regarding Innovative Manufacturing

The transformative impact of Pick and place robots on the industry is underscored by their practical applications in advanced manufacturing settings. The case studies provide insight into how they contribute to increased productivity, adaptability, and effectiveness.

Case Study 1: QJR10-1 Robots for Automation and Flexibility

Within a single cutting-edge manufacturing line, eight QJR10-1 pick-and-place robot units operate in unison to automate various tasks, including feeding workpieces, selecting completed items from injection molding machines, and cutting sprue gates. With a 6-axis range of motion, a 10kg payload capacity, and a repeat positioning accuracy of ±0.05mm, these robots exemplify the sophisticated functionalities of pick-and-place robots. This specific manufacturing line exemplifies the adaptability of pick-and-place robots by managing downstream operations for multiple models within a single line. Through the substitution of human labor with these robotic systems, the production line attains complete automation, which substantially amplifies operational efficiency and enables operations to function seamlessly with limited oversight from humans.

EVS3-400 Robots in 3C Product Assembly: Case Study 2

An additional noteworthy implementation of SCARA robots is discernible within a manufacturing line that integrates 3C (computer, communication, and consumer electronics) goods. The EVS3-400 robots play a crucial role in performing assembly, sorting, and handling duties. Their precise operation and rapidity have resulted in substantial labor cost savings and production uptime enhancements. In addition to enhancing production efficiency, the incorporation of these robots into the assembly line guaranteed the quality and uniformity of the products undergoing assembly.

Future Developments in SCARA Robotics

The trajectory of SCARA robots remains extensive, as continuous advancements in robotics are positioned to augment their functionalities and potential uses.

Developments and Innovations

The incorporation of machine learning and artificial intelligence (AI) technologies into SCARA robots will enable them to perform progressively intricate tasks with improved independence and flexibility. There is an expectation that progress in design and functionality will augment the adaptability of SCARA robotics, allowing them to perform tasks and manipulate a wider range of materials with heightened precision and efficiency.

What Implications Do Machine Learning and AI Possess?

By integrating AI and machine learning, SCARA robots will be capable of perpetually advancing and gaining insights from their own activities, thereby substantially augmenting their integration into intricate manufacturing procedures. By integrating these technologies, SCARA robots will possess the capability to rapidly acclimate to novel responsibilities, enhance their real-time performance optimization, and cooperate more efficiently with human operators.

Predictions in advance Concerning the Future

With the ongoing evolution of manufacturing processes, there will inevitably be an increased demand for autonomous systems that possess the capability to provide adaptability, effectiveness, and accuracy. SCARA robots, by virtue of their continuous technological progressions, are remarkably apt to fulfill these requirements, thus adopting a crucial position in the forthcoming manufacturing sector.

To conclude

The progression of SCARA robots from basic assembly line duties to intricate positions in advanced manufacturing highlights their importance within the industrial domain. Providing precision, efficiency, and adaptability that are unmatched, these robots have revolutionized manufacturing processes. It is evident that SCARA robots will persist in their development, assimilating with nascent technologies in order to satisfy the perpetually shifting requirements of the manufacturing industry. By adopting these advancements, manufacturers can anticipate increased productivity and competitiveness on the international market.

SCARA and pick and place robots‘ development exemplifies the revolutionary capacity of robotics in the manufacturing sector. The evolution of these systems is indicative of the industry’s more extensive transition towards automation and intelligent manufacturing—a trajectory that holds the potential to significantly influence production in the twenty-first century and beyond.