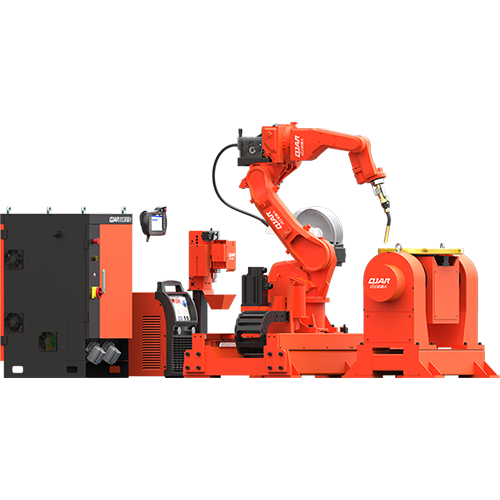

With the advent of six axis robots, the development of welding robots has advanced significantly. The QJR6-2000H and QJR6-1400H models from EVS are spearheading the modernization of welding procedures. Precision welding jobs are required by several sectors, and these six axis robots match those expectations with their great flexibility, accuracy, and efficiency. The QJR6-1400H and QJR6-2000H have remarkable features such as increased reach, improved payload capacity, and state-of-the-art technology, which guarantee excellent performance in a variety of production scenarios.

QJR6-1400H: Accuracy and Effectiveness

With a 1.4-meter reach and a 6 kilogram payload, the QJR6-1400H welding robot is made for precise work in small places. Its six-axis robot architecture makes smooth motion possible, which makes it ideal for sectors that need precise placement, such the automobile and electronics industries. Robotic repeat placement precision of ±0.08mm ensures reliable weld quality every time. The hollow joint design of this robot reduces noise and boosts productivity, enabling it to function flawlessly in calmer settings.

The QJR6-1400H is designed to maximize welding operations, particularly in situations where fine, tight welds are necessary. It can complete high-quality welds rapidly and with exceptional speed and agility, increasing production rates without compromising precision. This robot performs exceptionally well in applications that call for accuracy in tiny components and is perfect for light- to medium-duty work.

QJR6-2000H: Increased Flexibility and Reach

The QJR6-2000H has a 2.014-meter reach and a 6 kilogram payload, making it ideal for bigger jobs. This makes it the perfect welding robot for sectors like heavy machinery and automobile production that need long reach. It shares the same ±0.08mm repeat positioning precision as the QJR6-1400H, guaranteeing top-notch welding performance on every weld. This six-axis robot’s extended reach allows it to work on bigger components without sacrificing accuracy.

The adaptability of this robot is essential in sectors where reaching confined spaces is crucial. While operating at high speeds, the QJR6-2000H keeps precise and steady control. Because of its sophisticated motion control systems, it is ideal for precise, large-scale welding jobs.

Increasing Welding Efficiency with Six-Axis Robots

The QJR6-2000H and QJR6-1400H are the most automated welding robots available. They are extremely useful in sectors where perfect welds are required because of their six-axis robot construction, which enables them to move with quickness and accuracy. These robots have a clear edge when it comes to reaching difficult-to-reach places because of their six-axis rotational capability, which guarantees every weld is done precisely.

Manufacturers can increase production and drastically decrease human error by automating the welding process. These six axis robots run constantly to maximize productivity and guarantee little downtime. These robots deliver constant performance, which lowers rework and increases manufacturing process efficiency.

Modern Welding Tasks with Advanced Features

Modern technology is included with both versions to improve their operational capabilities. Hollow joint constructions in the QJR6-1400H and QJR6-2000H reduce internal cabling wear and minimize mechanical failures. These welding robots are appropriate for complicated operations because they include high-performance sensors and control systems that enable exact changes during welding.

These six axis robots offer a smooth workflow whereby robots cooperate to do difficult jobs quickly. They may be integrated into manufacturing lines. Their uninterrupted capacity to do welding jobs increases productivity, lowers operating expenses, and facilitates faster manufacturing turnaround times.

Six axis robots’ Place in the Manufacturing of the Future

Six axis robots will continue to be essential to welding robots in the future as technology develops. The QJR6-2000H and QJR6-1400H are the next generation of automation, providing speed, precision, and flexibility that are unmatched by manual labor. These robots will be much more beneficial to manufacturers trying to remain ahead of industry trends because of their ability to adapt to new duties with no retraining thanks to the integration of artificial intelligence (AI) and machine learning.

It is now mandatory for businesses looking to boost output while upholding the highest quality requirements to use six axis robots in their welding processes. With advancements aimed at increasing process efficiency and adapting to changing industrial demands, the future of welding robots is bright.

In summary

The best robotic welding technology is represented by the EVS QJR6-1400H and QJR6-2000H welding robots. These six axis robots are a vital tool in contemporary production because of their unmatched speed, precision, and versatility. These robots guarantee increased production, better quality, and lower costs by automating complicated welding procedures. Future production will be reshaped by welding robots like the QJR6-1400H and QJR6-2000H, which will be at the forefront of this movement as industries continue to change and automation becomes more important.