Introduction

Within the dynamic realm of industrial automation, the pursuit of technologically advanced solutions that are more agile, flexible, and efficient has resulted in noteworthy progress. Six axis robots and robot track systems, which are essential to attaining agility in automation, are at the forefront of this revolution. Recognized for their adaptability and accuracy, six-axis robotics have become essential in sectors spanning manufacturing to healthcare. The integration of robot tracks into these systems significantly expands their operational range and adaptability, thereby expanding the limits of what can be achieved in automated operations. This article examines the present functionalities of the aforementioned technologies, as demonstrated by the EVS Robot track and the 6kg payload 917mm reaching distance six-axis collaborative robot, and predicts their prospective development within the domain of agile automation.

Understanding Six-Axis Robots

Six-axis Robots: Definition and Characteristics

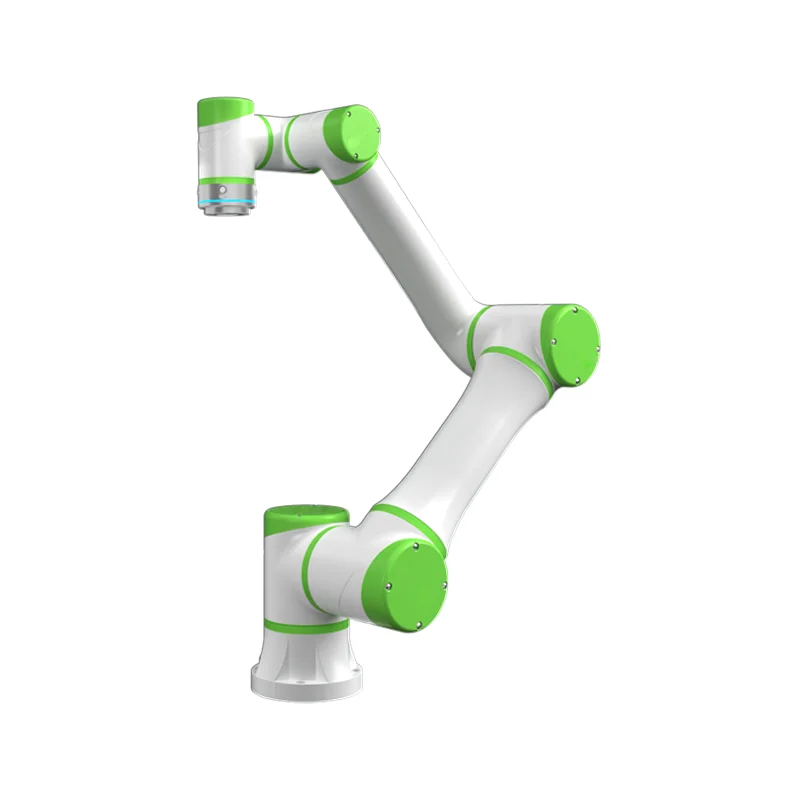

Six axis robots are distinguished by their six degrees of freedom, allowing them to move and rotate in six different ways. This flexibility enables them to perform complex tasks with high precision, from assembly operations to intricate welding. The 6kg payload 917mm reaching distance six axis collaborative robot (R6-093S) exemplifies this technology. Designed for tasks such as handling, palletizing, and arc welding, this cobot (collaborative robot) showcases high reliability and excellent performance, able to operate multiple procedures in narrow spaces due to its lightweight and compact structure.

Overview of the R6-093S

The R6-093S cobot is a testament to the advancements in six axis robot technology. With its collaborative feature, it extends operational capabilities, liberating humans from repetitive work and hazardous environments. The technical specifications, including a repeat positioning accuracy of ±0.02mm and an armspan of 917mm, underscore its utility in precise tasks. Its ability to operate at any angle and in varying environmental conditions further highlights the versatility and robustness of six axis robots in industrial applications.

The Role of Robot Tracks in Agile Automation

Extending Capabilities with Robot Tracks

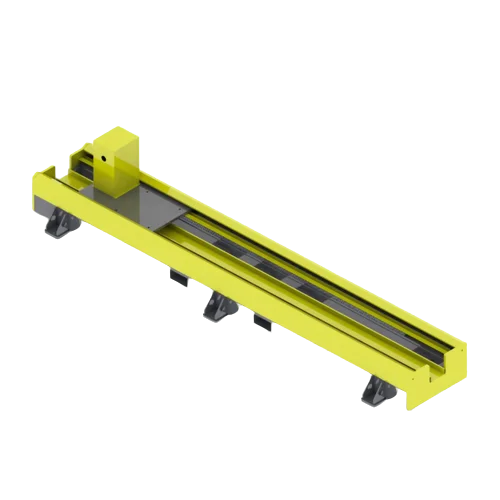

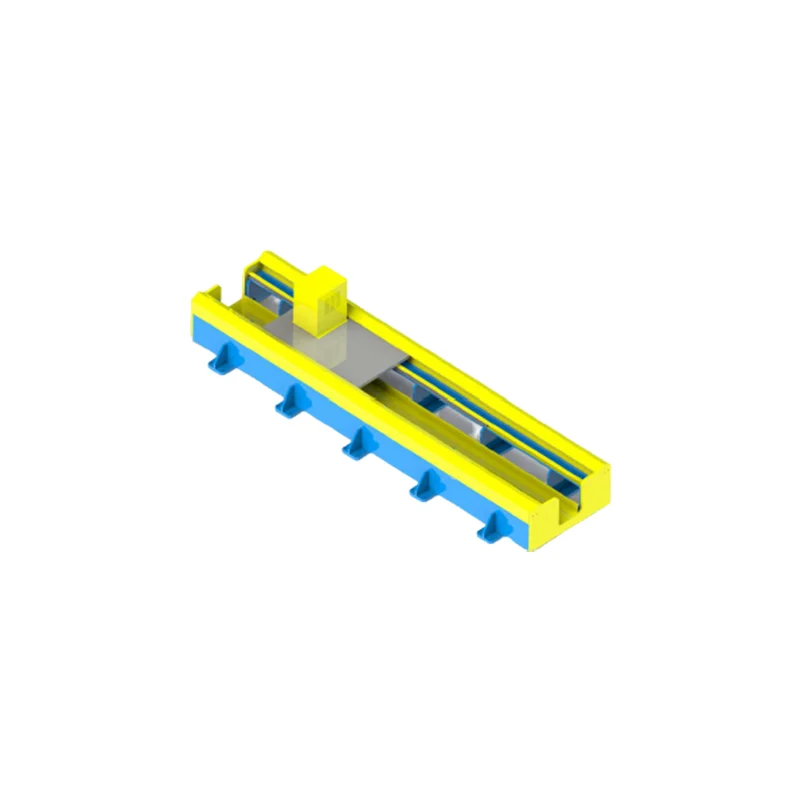

Robot tracks are critical in enhancing the operational range and flexibility of robotic systems. These tracks allow robots to move along a predefined path, expanding their working area beyond the fixed point of installation. The EVS Robot track, designed for applications such as welding, cutting, handling, machining, painting, and gluing, is equipped with a famous reducer and gear to ensure accuracy and stability. The ability to customize the rated load and length of the track to meet specific requirements makes robot tracks an invaluable component in achieving agile automation.

EVS Robot Track: A Closer Look

The technical specifications of the EVS Robot track highlight its role in agile automation. With a repeat positioning accuracy of up to ±0.10mm for payloads under 1000kg, the track ensures precise movement of the attached robot. The standard length of 4000mm, extendable in increments, along with options for ground mounting, provide flexibility in configuring automated systems to suit various operational needs. This adaptability, coupled with the track’s semi-enclosed sheet metal protection and self-lubrication system, ensures reliable and efficient performance in a range of industrial settings.

Integrating Six-axis Robots with Robot Tracks

In the field of agile automation, the incorporation of six axis robots with robot tracks represents a significant advancement. By virtue of this amalgamation, mechanized systems not only attain heightened adaptability and effectiveness, but also substantially broaden their operational scope and functionalities.

Synergistic Relationship Between Six axis Robots and Robot Tracks

The collaboration between six axis robots and robot tracks creates a dynamic duo capable of undertaking complex automation tasks with unprecedented agility and precision. Six axis robots, with their dexterity and versatility, can perform a wide array of tasks, from intricate assembly operations to precise welding. When mounted on robot tracks, these robots gain the ability to traverse large distances, thereby increasing their utility in tasks such as large-scale material handling and assembly line work. This integration allows for a seamless flow of operations across different sections of a manufacturing or processing facility, ensuring efficiency and productivity are maximized.

Case Studies: Enhanced Productivity and Precision

Practical applications of six axis robots combined with robot tracks are numerous and varied. In automotive manufacturing, for instance, this integration has revolutionized assembly line efficiency, allowing for the rapid and precise installation of components across different stages of assembly. Another case study in the electronics industry showcases how these systems can be employed for the meticulous placement of components on circuit boards, with robot tracks enabling the six axis robots to access multiple workstations without the need for human intervention. These examples underline the technical and operational benefits of integrating six axis robots with robot tracks, including improved efficiency, expanded operational range, and enhanced precision.

Future Trends and Innovations

The future of six axis robots and robot tracks holds exciting potential, with ongoing research and development poised to bring about significant innovations in these technologies.

Six-axis Robot and Robot Track Developments

Emerging trends in robotics technology point to a focus on making six axis robots even more collaborative and intelligent, with improved sensory capabilities and integrated AI for improved decision-making and autonomy. In a similar vein, progress made in the domains of materials science and engineering has resulted in the development of track systems that exhibit enhanced adaptability, reliability, and portability—all of which contribute to the improved accuracy and versatility of robot tracks. Additionally, the incorporation of Internet of Things (IoT) technology into these systems can improve their connectivity and facilitate instantaneous monitoring, resulting in automation solutions that are more thoughtful and adaptable.

Conquering Obstacles by Means of Innovation

However, the journey towards these advancements is not devoid of obstacles. One of the most important is the requirement for enhanced interoperability and compatibility among various robotics systems and components. Standardized protocols and interfaces, in addition to developments in robotics software and control systems, will be required to address these issues. Furthermore, the pursuit of energy-efficient and environmentally sustainable robotics solutions will spur advancements in power management technologies and materials.

Prototyping the Subsequent Iteration of Agile Automation

The landscape of industrial automation is about to change as six axis robots and robot tracks develop. The next iteration of agile automation solutions will manifest as these technologies advance and integrate further. These solutions will be distinguished by unparalleled levels of intelligence, flexibility, and efficiency.

Consolidation Utilizing Emerging Technologies

It is anticipated that emergent technologies such as AI, machine learning, and IoT, in conjunction with six axis robots and robot tracks, will produce highly autonomous systems capable of adapting to changing operational environments and making complex decisions. In addition to augmenting the productivity and efficacy of current manufacturing and processing operations, these systems will facilitate the implementation of novel automation techniques that were hitherto unattainable.

Determining the Course of Industries

As one contemplates the forthcoming years, the prospective uses of these sophisticated autonomous systems are extensive and diverse, encompassing sectors apart from manufacturing such as healthcare, logistics, and space exploration. The integration of six axis robots and robot tracks, along with their escalating intelligence and connectivity, holds the potential to revolutionize automation by fostering innovation and expansion in a wide array of sectors.

Conclusion

A significant advancement in the field of agile automation is the incorporation of six axis robots with robot track systems. As we contemplate the prospective trajectory of these technologies, it becomes evident that their ongoing development will persistently propel substantial progressions in industrial automation, providing not only more streamlined and adaptable solutions, but also more intelligent and interconnected ones. By wholeheartedly adopting these advancements, sectors across the globe can anticipate a future in which automation serves not only as a productivity enhancer but also as a catalyst for profound change, unveiling uncharted territories in manufacturing and beyond.