Overview

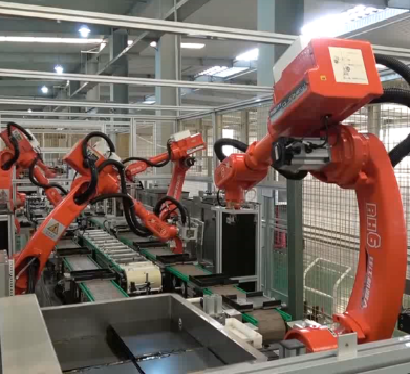

Automation technology is becoming an essential component of today’s industrial industry and has set the groundwork for future advancements in this subject in our technologically evolved society. With its six axis robots, which offer unmatched flexibility, accuracy, and high efficiency and are influencing advancements in automation technology, including assembly robots, EVS has accomplished remarkable feats in the field of automation technology. For example, EVS‘s QJR20-1600, QJR10-2 and QJR210-1 six axis robots in the assembly robots. This article will introduce the advantages and functions of these advanced robotic arms, as well as their impact on future industrial automation.

An Introduction to Six-Axis Robots

Six axis robots are industrial robots with six degrees of freedom. With this setup, they may move in six different directions: forward, backward, left, and up. Additionally, they are able to spin around three orthogonal axes. Because of their versatility, six axis robots can perform complex tasks with remarkable precision and adaptability. These robots are widely used for tasks including packing, material handling, welding, and assembly across several industries.

The Assembly’s Function Industrial Automation using Robots

Assembly activities can range from basic component assembly to complex, high-precision operations, and assembly robots are particularly made to handle these kinds of tasks. These assembly robots greatly increase manufacturing productivity and product quality since they can work at fast rates and consistently with accuracy. Assembly robots not only improve productivity and accuracy but also improve worker safety by assuming dangerous duties and lowering the possibility of accidents.

EVS QJR20-1600: Reliability and Flexibility

Among EVS’s selection of six axis robots in the assembly robots, the QJR20-1600 model stands out in particular. It can support up to 20 kg of weight and has a maximum reach of 1671 mm. Because of its payload capacity and reach, it is ideal for a wide range of industrial applications, including assembly, welding, palletizing, and material handling.

Principal characteristics and benefits:

Elevated Accuracy: With a repeat positioning precision of ±0.05mm, the QJR20-1600 guarantees consistent and precise operation. Applications requiring painstaking attention to detail, including electronics assembly and car manufacture, require this degree of accuracy.

Robustness: The QJR20-1600’s superior materials construction allows it to run effectively in a range of conditions for an extended amount of time without experiencing performance deterioration. This is largely because of its sturdy build and Flexibility: The QJR20-1600 can adapt to a wide range of work in a wide variety of areas thanks to its multiple functionalities. Its applications are mostly found in palletizing, welding, and material handling.

EVS QJR10-2: Increased Flexibility and Range

Another remarkable six axis robots in the assembly robot from EVS is the QJR10-2, which has a maximum reach of 2001mm and can carry a 10 kilogram payload. It is appropriate for activities requiring great precision and coverage of bigger workspaces because to its increased reach.

Principal attributes and advantages:

Increased Range: Because of its 2001mm reach, the QJR10-2 is perfect for applications like welding, assembly, and material handling in big production lines, where it can work in wider workspaces.

Sophisticated Control Systems: The QJR10-2 has advanced control systems that enable streamlined and effective operation. These solutions increase overall productivity by enabling the robot to carry out difficult jobs quickly and accurately.

endurance: The QJR10-2 is made of premium materials and is designed to resist harsh industrial settings. This ensures dependable performance and long-term endurance. It is a solid asset in any production setting because of its sturdy construction.

EVS QJR210-1: Performance for Heavy Lifting

The QJR210-1 is the best option for applications that need to handle large loads. With a maximum reach of 2688mm and the capacity to manage a weight of up to 210kg, this six axis robots in the assembly robot is ideal for large-scale production operations.

Principal attributes and advantages:

High Capacity Payload: The QJR210-1 has a 210 kg payload capacity and is made to carry large loads. This makes it ideal for jobs involving big and heavy component handling, such welding, assembling, and palletizing, in many sectors.

Increased Range: The QJR210-1’s 2688mm reach allows it to span expansive workplaces, making it flexible for a range of industrial applications. This wider scope is especially helpful for sectors like construction and car manufacture.

Accuracy & Precision: The QJR210-1 has a high payload capacity but retains a ±0.2mm repeat positioning accuracy. This degree of precision guarantees accurate and dependable operation, even for demanding jobs.

Industrial Automation’s Future Using EVS Six-Axis Robots

Increased Accuracy and Output

The capacity of EVS six axis robots in the assembly robots to carry out jobs with extreme consistency and accuracy is one of their biggest advantages. Since robots can do repeated activities without the unpredictability inherent with human labor, this accuracy results in superior product quality. These six axis robots can also work at very fast rates, which greatly increases output and productivity.

Enhanced Safety at Work

Assembly robots can do dangerous jobs, saving human workers from potential harm. These six axis robots make workplaces safer by automating hazardous jobs like welding and material handling. In addition to safeguarding employees, this reduces lost time from work caused by accidents at work.

Lower Operating Expenses

Six axis robots in the assembly robots may have a large initial cost, but there will be considerable long-term cost reductions. These six axis robots minimize downtime, cut down on costly errors, and eliminate the need for physical work. Savings are further aided by their longevity and minimal maintenance requirements.

Increased Adaptability

EVS Six axis robots in the assembly robots’ adaptability enables producers to adjust to shifting production demands. Because these six axis robots are programmable, industrial processes may be made more flexible. In today’s dynamic industrial industry, where businesses need to be able to react swiftly to market demands, this flexibility is essential.

In summary

The Six axis robots in the assembly robots from EVS, the QJR20-1600, QJR10-2, and QJR210-1, are the industrial automation of the future. With their accuracy, adaptability, and cutting-edge technology, these robots provide enterprises in a wide range of sectors with countless advantages. Businesses may increase productivity, boost flexibility, and improve product quality by incorporating these robotic arms into their manufacturing lines. This will put them in a competitive position within the industry.

See the following websites for further information on these goods in greater detail:

QJR10-2 QJR210-1 QJR20-1600 With EVS‘s Six axis robots in the assembly robots, you can embrace the future of industrial automation and improve your production operations.