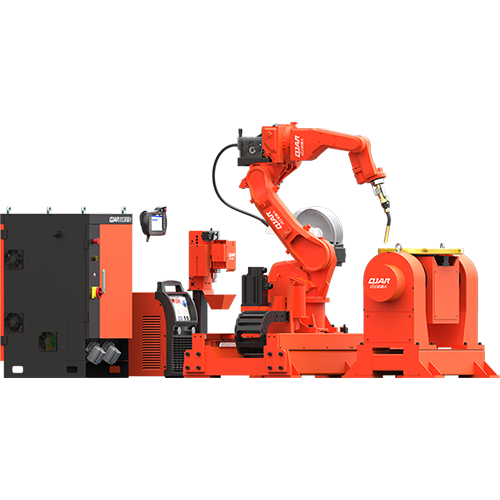

With laser welding robots setting the standard for increased productivity, accuracy, and efficiency, robotics in manufacturing is evolving quickly in today’s industrial environment. The QJR6-1400H and QJR6-2000H are two extraordinary models offered by EVS, a pioneer in robotic systems. With their unequaled precision and agility in a range of production conditions, these laser welding robots are revolutionizing the way industries handle complicated welding jobs.

Manufacturing with Compact Precision—QJR6-1400H

When it comes to small to medium-sized welding activities, the QJR6-1400H laser welding robot provides remarkable precision. This robot is the best at tasks when accuracy is crucial, thanks to its 6 kg payload and 1.4 m reach. Every weld is precise and reliable because of its six-axis flexibility, which enables it to operate in confined locations. The automotive, electronics, and aerospace sectors find the QJR6-1400H to be a perfect option for robotics in manufacturing due to its repeat positioning accuracy of ±0.08mm.

The QJR6-1400H’s small size minimizes its footprint on the factory floor while yet enabling it to handle complex welding jobs. This robotic laser welder streamlines manufacturing processes, lowers mistake rates, and improves product quality by automating repetitive activities.

Expanded Scope for Bigger Initiatives: QJR6-2000H

The industry standard for larger-scale welding operations is the QJR6-2000H. Larger components may be joined together with this laser welding robot thanks to its expanded 2.014-meter reach and 6 kg payload. Comparable to the QJR6-1400H, the QJR6-2000H guarantees accurate repetition placement with a ±0.08mm accuracy, guaranteeing each weld. This particular robotics in manufacturing model is particularly well-suited for applications in heavy machinery, construction, and shipbuilding, all of which need precise welding of huge components.

Even in intricate assemblies, the QJR6-2000H’s longer reach and six-axis flexibility allow it to consistently provide welds in difficult-to-reach places. The laser welding robot improves industrial process efficiency by automating these large-scale processes, which lowers personnel expenses.

Effects of Robots Welding Lasers on Manufacturing Robotics

Significant improvements in the way industries approach welding have resulted from the integration of laser welding robots with robotics in manufacturing. With their unparalleled precision, laser welding robots such as the QJR6-1400H and QJR6-2000H minimize error margins and improve overall product quality. In areas where complex welding on delicate materials is necessary, like aerospace or medical device manufacture, this degree of precision is extremely crucial.

Laser welding robots also offer increased productivity and speed. Manufacturers may cut downtime and do away with the necessity for manual labor—which frequently results in irregularities—by automating welding activities. Laser welding robots can perform more jobs in less time since they can function constantly, which improves production lines and boosts productivity.

Six Axis Robotics: Increasing Flexibility in Application

Models like the QJR6-2000H and QJR6-1400H demonstrate six-axis flexibility, a trait that greatly increases the versatility of laser welding robots in production. These robots have six degrees of freedom, so they can move in different directions and weld from different angles and locations. This flexibility allows the robot to access hard-to-reach areas without having to reposition the workpiece, which is essential in sectors that deal with complicated components.

Faster production times and more consistent outputs are two benefits of this flexibility in robotics in manufacturing. Robots that use laser welding technology automate tasks that would often need human involvement, resulting in faster and more precise welding operations.

Automated Production in Contemporary Times

Automation is a major trend in manufacturing that is only going to get bigger, and laser welding robots are leading the way in this regard. The autonomous operation of the QJR6-2000H and QJR6-1400H reduces the need for human supervision and enables continuous manufacturing. Attaining this degree of automation increases efficiency and minimizes the possibility of human mistake, guaranteeing optimal performance throughout each weld.

Production line manufacturers may increase product quality, save labor costs, and streamline their processes by utilizing laser welding robots. These robots can perform the same work with flawless accuracy every time, which is particularly beneficial to companies that depend on consistent, high-quality welds.

To sum up

In conclusion, with their unparalleled productivity, accuracy, and flexibility, the game-changing QJR6-1400H and QJR6-2000H laser welding robots are revolutionizing robotics in manufacturing. The purpose of these laser welding robots is to automate intricate welding operations in order to minimize error margins and enhance industrial workflows. Laser welding robots will become more and more popular as manufacturing technology develops, making them crucial tools for businesses attempting to maintain worldwide market share.