A new age in manufacturing and logistics has begun with the incorporation of automation into industrial processes; this has resulted in the transformation of activities from production facilities to distribution centers. Assembly machines have evolved as pivotal components among these technological marvels, exerting a substantial impact on productivity, efficiency, and dependability. The “20kg Payload 1668mm Reaching Distance Robotic Arm QJR20-1600” serves as a prime illustration of how sophisticated robotics technology is revolutionizing the domains of manufacturing and logistics. It portends a forthcoming era in which the collaboration between machines and humans is more seamless than ever before.

The Proliferation of Robotic Assembly in Manufacturing

The advent of assembly robotics has brought about an unprecedented level of automation, precision, and velocity in the realm of manufacturing. These mechanical marvels are designed to perform an extensive array of operations with remarkable accuracy and uniformity, spanning from fundamental component positioning to complex assembly procedures.

The QJR20-1600: An Indicator of Progress

The “20kg Payload 1668mm Reaching Distance Robotic Arm QJR20-1600” exemplifies the progress made in the field of assembly robot technology at present. By virtue of its explosion-proof capability, it is the inaugural product of its kind on the domestic market, underscoring the contemporary autonomous design paradigm that prioritizes both safety and adaptability. With an impressive reach of 1668mm and a high repeat positioning accuracy of ±0.05mm, this robotic arm is highly proficient in executing a diverse array of operations, such as palletizing, handling, loading, offloading, laser cutting, and sprinkling, among other responsibilities.

The six axes of motion of the robot afford it the necessary flexibility to traverse intricate tasks, thereby guaranteeing its adaptability to a multitude of manufacturing sector applications. The critical importance of assembly robots in improving production line efficiency, minimizing outages, and upholding quality standards is underscored by their speed and accuracy.

The Shift Toward Logistics

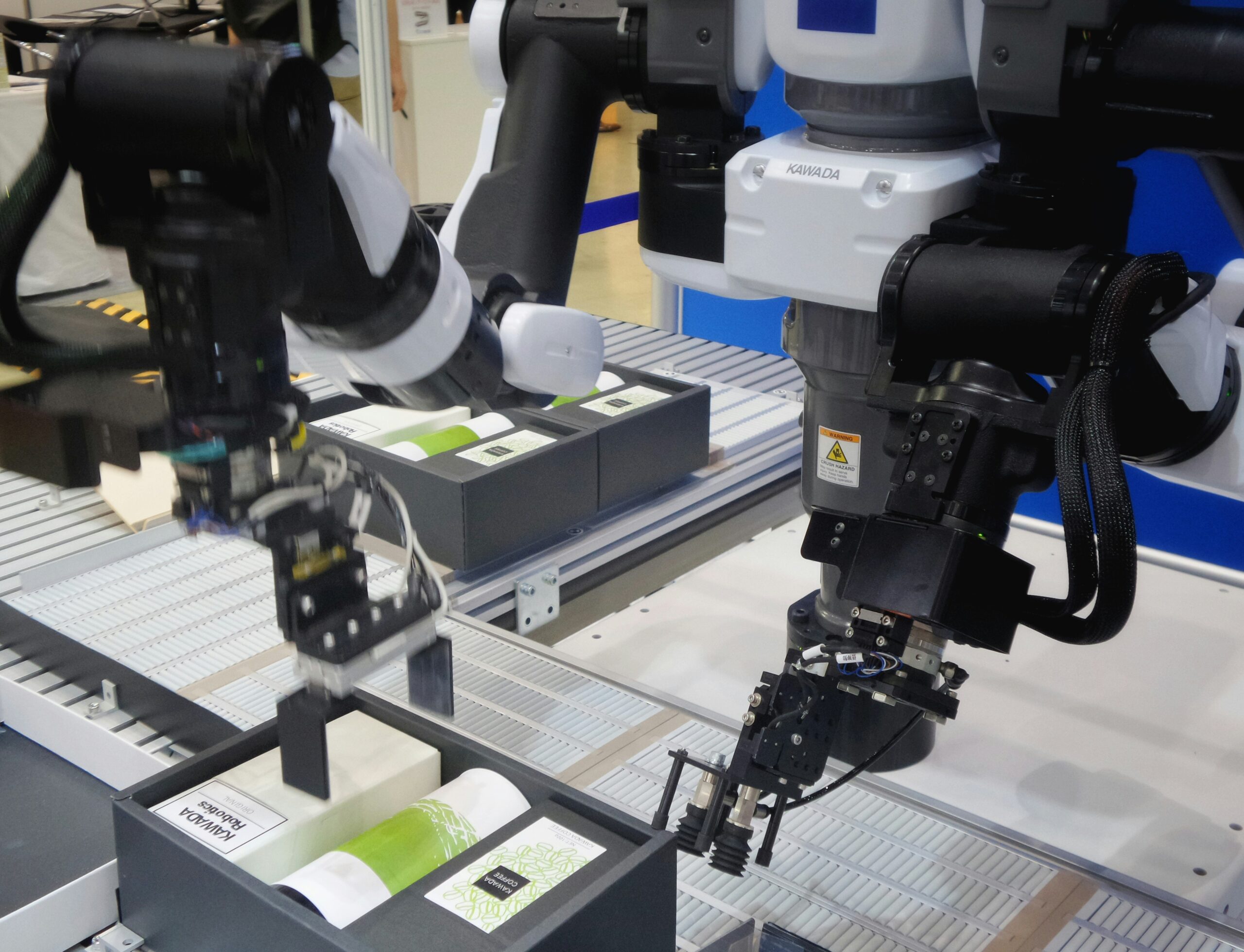

The influence of assembly robots transcends the domain of manufacturing and has a substantial impact on distribution and logistics operations. The implementation of robotics in the field of logistics has brought about a transformed process of assembly, packaging, and sorting of products within distribution centers.

Logistics Automation: Assembly Robots Beyond Manufacturing

Integration of the QJR20-1600 and analogous assembly robots into logistics operations, where efficiency and accuracy are of equal importance, is feasible due to their adaptability. These robots can automate duties that were previously carried out by human employees in distribution centers, including package assembly, classification, and preparation for shipment. This reduces the likelihood of human error and accelerates the logistics process, ensuring that orders are processed precisely and efficiently.

The integration of assembly robotics into logistics yields numerous advantageous outcomes. Enhanced operational velocity, improved precision, and decreased labor expenditures all contribute to a supply chain that is more streamlined and economical. Moreover, operating continuously without experiencing fatigue enables robots to substantially enhance productivity, thereby satisfying the escalating expectations of customers in the contemporary, fast-paced marketplace.

Logistics Robotics: More Than Just Assembly Lines

Although assembly robots, such as the QJR20-1600, have established their value in the manufacturing sector, their utilization in logistics illustrates the wider capacity of robotics to revolutionize conventional supply chain processes. Inventory management, order fulfillment, and shipping are all aspects of logistics where robotics is integrated, demonstrating a transition toward fully automated distribution centers.

The Augmentation of Supply Chain Efficacy

In addition to streamlining physical duties, robotics in logistics optimize inventory management and order monitoring through integration with digital systems. The convergence of digital innovation and physical automation fosters a streamlined supply chain that is more agile and responsive to fluctuations in demand, thereby diminishing lead times.

An even more promising trajectory lies in the integration of AI and machine learning technologies into the field of logistics automation in the future. These advancements may empower robotic systems to make decisions based on data, thereby augmenting operational effectiveness and diminishing wastage throughout the supply chain.

Workstation for Robotic Screw Driving: A Case Study

An instance that exemplifies the adaptability and effectiveness of assembly robots is a robotic screw driving workstation that was specifically engineered for the assembly of automotive powertrains. The precision of executing multiple screwdriving tasks concurrently is enhanced by the “20kg Payload 1668mm Reaching Distance Robotic Arm QJR20-1600,” which includes a multi-axis screw driving head on this workstation.

Transforming Automotive Assembly

The incorporation of the autonomous arm into the assembly procedure has substantially improved the efficiency, precision, and uniformity of the output. The assembly robot not only accelerates the assembly line but also guarantees that every engine is assembled in accordance with the highest quality standards by automating the screwdriving procedure. This automation exemplifies the capacity of assembly robots to furnish the automotive industry with all-encompassing solutions, thereby streamlining production lines and diminishing expenses associated with manual labor.

Difficulties and Opportunities

Although the implementation of assembly robotics in manufacturing and logistics signifies a paradigm shift toward increased productivity and efficiency, it also introduces a number of obstacles. The aforementioned factors comprise the initial investment requirement, the necessity for proficient personnel to operate and maintain the robotics, and the incorporation of these systems into pre-existing workflows.

Maneuvering Beyond Obstacles

In order to maximize the advantages offered by assembly robots, organizations must confront these obstacles via strategic foresight, financial commitment to training initiatives, and incremental incorporation of robotics into their daily processes. Furthermore, it is anticipated that the ongoing development of robotic technology will eventually diminish these obstacles, rendering robotics more readily obtainable and versatile across diverse sectors.

Exploring Untapped Potential

The potential benefits that assembly robots and robotics in logistics can offer are extensive. In addition to mechanizing mundane duties, these technologies have the potential to augment safety in the workplace by assuming hazardous or physically taxing positions. In addition, as robots advance in intelligence and proficiency in handling intricate duties, they have the potential to unveil novel opportunities for customization, innovation, and service provision beyond the realm of logistics.

The Prospects for Assembly Robots and Logistics Robotics

The trajectory of robotics in the domains of manufacturing and logistics indicates a future characterized by heightened automation and intelligence. As illustrated by systems such as the “20kg Payload 1668mm Reaching Distance Robotic Arm QJR20-1600,” the integration of AI and machine learning with assembly robots suggests a future in which robots are not merely task executors but also decision-makers, capable of optimizing processes in real-time.

Towards More Intelligent and Adaptable Automation

We can anticipate robots that are more adaptable, capable of acquiring knowledge from their surroundings, and capable of collaborating with humans more efficiently as technology progresses. In addition to bolstering the functionalities of manufacturing and logistics operations, this transformation will also reshape the essence of labor, engendering novel positions and prospects within these domains.

Conclusion

Distribution centers and factory floors have all been profoundly affected by assembly robots in the realms of logistics and manufacturing. Such technologies as the “20kg Payload 1668mm Reaching Distance Robotic Arm QJR20-1600” are at the vanguard of this technological revolution, presenting industries around the globe with both challenges and opportunities. The ongoing incorporation of robotics, artificial intelligence, and machine learning into the domains of logistics and manufacturing holds the potential to yield further advancements in productivity, adaptability, and ingenuity. The trajectory of robotics in these industries is nascent, and its complete capabilities have yet to be actualized; this augurs a future in which the boundaries of possibility are merely figments of our imagination.