Introduction

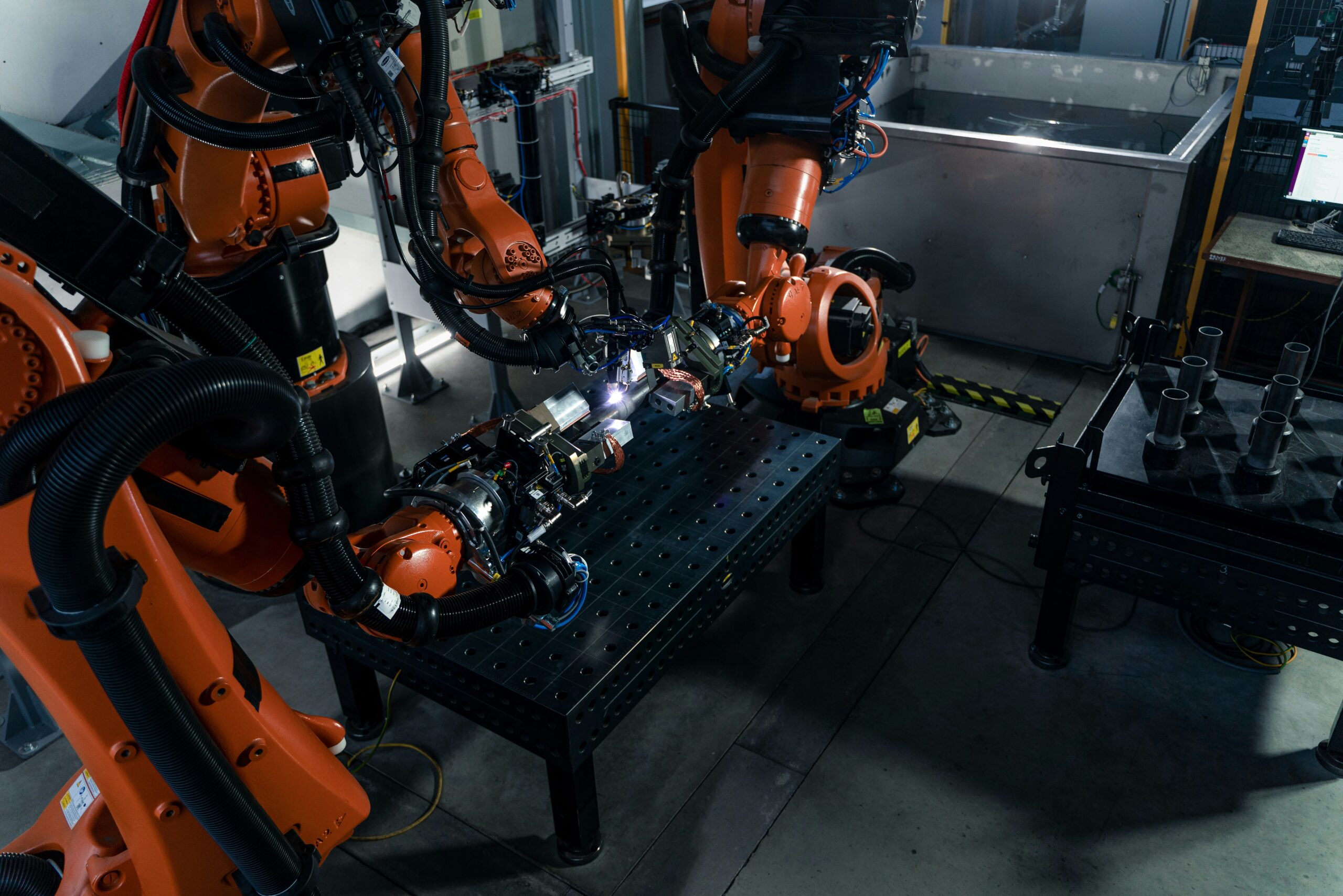

The sustainability and structural soundness of products are significantly influenced by the caliber of welds utilized in contemporary manufacturing. Welding robots and welding positioners have become indispensable tools in the pursuit of unrivaled weld quality as industries pursue perfection. This article explores the substantial influence that these technologies have on the performance of robotic welding, with particular emphasis on particular products and their means of augmenting weld accuracy and productivity.

Comprehending Robotic Welding

Welding Robots: An Overview

Designed to execute welding operations with extreme consistency and accuracy, welding robots are mechanized devices. Precise execution of intricate welding procedures is possible due to the sophisticated sensors, controllers, and actuators that comprise these robots. By delivering consistent welds with minimal human intervention, welding robots diminish the possibility of errors and boost production efficiency, which is their primary benefit in the manufacturing sector.

QJR6-1400H is the Highlighted Product

The QJR6-1400H is a notable instance of one of the most cutting-edge welding robots. A widely recognized option across multiple sectors, this 6-axis welding robot is renowned for its cost-effectiveness and exceptional performance.

Descriptive Aspects

6 axis repeat positioning with a 1.4 meter reaching distance 0.08mm precision

1456 mm in span

Features

The QJR6-1400H is distinguished from industry-comparable products by the following innovative features:

Gip Adjustment of the Joint Gear: This characteristic enables precise welding operations through rapid dynamic response and fine control.

The hollow joint support structure provides the robot with increased flexibility and rigidity, allowing it to effortlessly perform a variety of welding tasks.

The minimal disruption to operation caused by the robot’s noise reduction structure contributes to a quieter working environment.

Stainless steel, carbon steel, aluminum, and copper are within the range of materials that this welder is capable of processing. Industries such as automotive, aerospace, and heavy machinery production are all viable applications for its adaptability.

Welding Positioners: Their Function

Welding Positioners: An Overview

To maintain the workpiece in the optimal welding position, welding positioners are utilized. By guaranteeing the proper positioning of the workpiece, welding positioners enhance the efficiency and precision of the welding procedure. These tools ensure the required stability and control to generate welds of exceptional quality, which can be of great benefit to complex-weld applications.

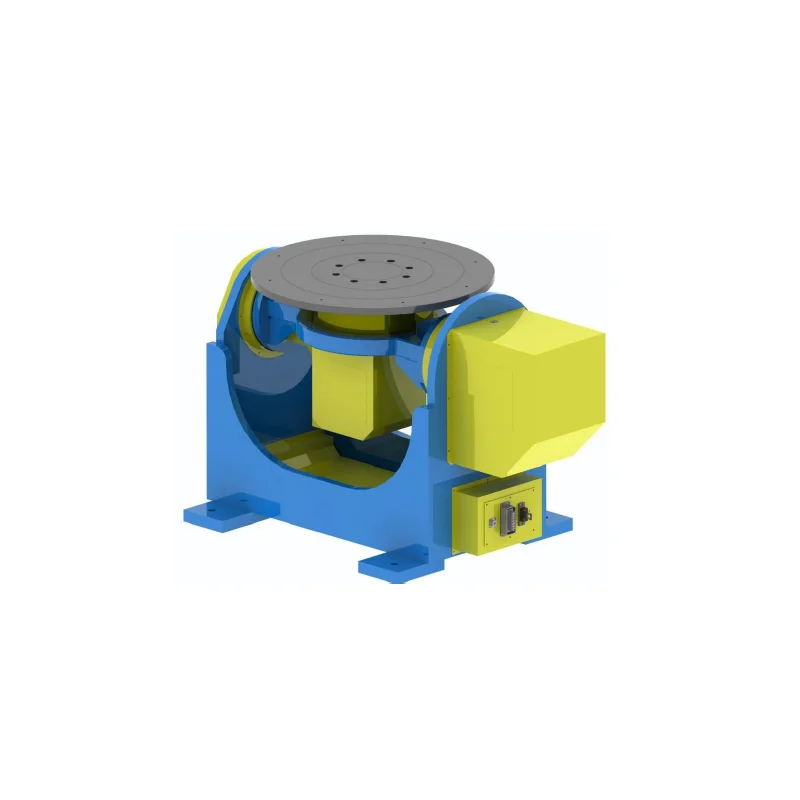

EVS-DWP-P-200/500/1000 is the Highlighted Product

With a broad spectrum of welding applications in mind, the EVS-DWP-P-200/500/1000 is an innovative welding positioner. Sophisticated characteristics of this double-axes servo positioner guarantee superior stability and accurate operation.

Descriptive Aspects

Repetition Accuracy: ±0.10mm, ±0.12mm, and ±0.20mm; Rated Load: 200kg, 500kg, and 1000kg

Approved Gym Velocity along the first axis: 70°/S, 50°/S, 15°/S

Eighth-rated axis two gyration speed: 70°/S, 24°/S

Features

Multiple performance-enhancing features are incorporated into the EVS-DWP-P-200/500/1000:

Implementing a Double Axes Servo System guarantees accurate and consistent welds by granting precise command over the positioner’s motions.

Constructed from premium materials and undergoing stringent machining procedures to guarantee both longevity and accuracy, the positioner is of superior quality.

The selection of brass conductive material guarantees exceptional electrical conductivity, thereby augmenting the overall welding process efficiency.

Owing to its high stability and low failure rate, the positioner is operated under the control of an Omron PLC.

Welding positioners are highly suitable for tasks requiring exceptional load capacity and precision. Sectors of the automotive, aerospace, and heavy machinery manufacturing industries can derive advantages from the advanced functionalities and robust construction of this product.

Positioners’ Complementarity with Welding Robots to Improve Robotic Welding

The synergistic effect produced by the integration of welding positioners and welding robots simplifies the process of attaining optimal welding performance. Welding positioners maintain the workpiece in the ideal position, allowing for more accurate and efficient welding robot operations. Enhanced weld quality, increased production throughput, and reduced defects are the results of this amalgamation.

Consequences for Weld Quality

Weld quality is vastly affected by the implementation of welding robots and positioners. The technologies provide precise control, which dramatically reduces the probability of defects and rework by ensuring that every weld is executed with exceptional accuracy. Furthermore, improved access to difficult-to-reach areas is made possible by the competency to properly position the workpiece, which produces welds that are more consistent and dependable.

Illustrative Case Study

Implementation of Case Study 1 in the Automotive Sector

Assembly of automobile bodies and other components typically requires the utilization of welding robots and positioners. Welds of superior quality that adhere to rigorous industry standards can be produced by manufacturers through the integration of positioners such as the EVS-DWP-P-200/500/1000 with welding robots like the QJR6-1400H. Product quality and production efficiency have gained substantially as a result of this integration.

Application of Case Study 2 to the Aerospace Firm

In regards to welding operations, the aerospace sector places the utmost importance on accuracy and dependability. Strict but reliable joints are produced through the utilization of sophisticated welding robots and positioners, which guarantee the highest degree of precision during each weld. Components of aerospace of superior quality that satisfy the industry’s stringent safety and performance standards have been manufactured with the assistance of this technology.

Heavy Machinery Production: Case Study No. 3

Positioners and welding robots collaborate to facilitate the efficient manipulation of sizable and intricate components during the production of heavy machinery. The technologies in question provide the accuracy, consistency, and control necessary to perform every weld precisely, thereby resulting in machinery that is solid and dependable.

In summary

A Concise Overview of Principal Aspects

By providing unparalleled precision, efficiency, and quality, the integration of welding positioners and welding robots has revolutionized the welding industry. Exemplary products of this domain include the EVS-DWP-P-200/500/1000 positioner and the QJR6-1400H welding robot, which furnish manufacturers with the necessary equipment to consistently generate welds of superior quality.

Subsequent Trends

It is foreseeable that robotic welding and positioner systems will undergo additional developments as technology progresses. Further advancements in weld quality and efficiency are probable as a result of the substantial impact that emerging trends like artificial intelligence and machine learning will have on the capabilities of these technologies.

Concluding Reasons

Assemblies of welding positioners and welding robots are indispensable in an industry where quality and accuracy are of sacred proportions. In addition to improving the quality of welds, these technologies foster greater cost reduction and enhanced production efficiency. Welding appears to have a bright future, as on-going advancements and improvements are anticipated as more and more manufacturers adopt these sophisticated tools.