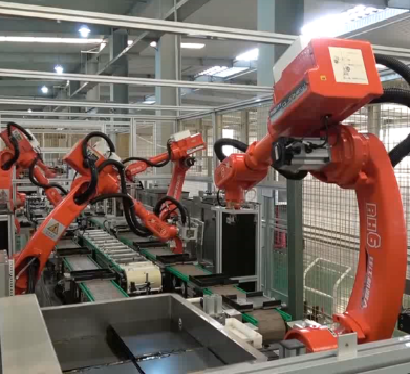

How items are handled, processed, and transferred across production lines is changing in the modern industrial world thanks to smart logistics technologies. The assembly robot, which improves logistical efficiency and accuracy, is a vital part of this revolution. Leading robotics solutions provider EVS provides state-of-the-art assembly robots like the QJRB15-1 and QJRB30-1. These robots help companies remain competitive in an era of automated, fast-paced operations by streamlining procedures.

How Assembly robots Are Changing Intelligent Logistics

Assembly robots are automating tedious jobs and boosting productivity in contemporary supply chains, redefining smart logistics. Robots that are specifically engineered to satisfy the requirements of smart logistics include the EVS QJRB15-1 and QJRB30-1 types. With its 15 kilogram payload and 1510 mm reach, the QJRB15-1 is the perfect tool for light to medium-weight jobs. In the meanwhile, heavier components can be handled by the QJRB30-1, which has an 1820mm reach and a 30kg payload. In smart logistics systems, both robots automate assembly procedures, guaranteeing uniformity and lowering human error.

Businesses may automate labor-intensive processes like choosing, putting, and assembling items by using assembly robots. Because of the accuracy of the robots, errors are less likely to occur while handling items. Automation is a key component of smart logistics systems, and assembly robots are essential to making sure these systems run as efficiently as possible and produce results on schedule.

Assembling Robots’ Advantages for Intelligent Logistics

There are several advantages to integrating assembly robots into smart logistics, such as higher accuracy and faster manufacturing. Automating processes like component assembly, handling, and packing using the EVS QJRB15-1 and QJRB30-1 will make operations quicker and more dependable. These assembly robots are perfect for high-demand settings where speed is crucial since they can operate nonstop without needing to take breaks. The capacity of assembly robots to lower labor costs is a key benefit in smart logistics.

Assembly robots’ adaptability in logistics systems

The versatility of assembly robots is one of its most notable qualities in smart logistics. The EVS QJRB15-1 and QJRB30-1 robots are very adaptable in various production environments since they can be programmed to do a wide range of jobs. These assembly robots offer the flexibility required to adapt to shifting production demands in smart logistics settings, whether they are handling heavy materials in an automotive supply chain or assembling tiny electronic components.

Flexible assembly robots are becoming ever more essential in smart logistics as companies embrace more agile manufacturing tactics. Because of their fast adjustment capabilities, the QJRB15-1 and QJRB30-1 robots allow firms to adapt to changes in demand without compromising on quality or production.

Increasing Precision and Decreased Errors with Assembly robots

The precision of smart logistics operations is significantly improved by assembly robots. Manual labor cannot match the accuracy with which these robots can handle materials and complete jobs. EVS’s QJRB15-1 and QJRB30-1 models are capable of reproducing intricate assembly operations precisely, guaranteeing that each result fulfills the same requirements. This consistency improves overall product quality and lowers mistakes, which is a major benefit of smart logistics systems.

Assembling, packing, and shipping goods fast is typically necessary in smart logistics, therefore assembly robot precision is crucial. By removing the possibility of human mistake in repeated operations, these robots assist organizations in maintaining high standards of productivity and quality control. Utilizing assembly robots guarantees that mistakes like misalignment or improper assembly are reduced, which lowers the number of product recalls and raises customer satisfaction.

Assembly robots’ Future in Intelligent Logistics

As technology develops, assembly robots will keep being a major factor in how smart logistics are shaped going forward. Leading the way in automating assembly procedures and improving the overall effectiveness of logistics systems are robots such as the EVS QJRB15-1 and QJRB30-1. As artificial intelligence and machine learning are combined, assembly robots will become increasingly more intelligent. This will allow them to respond to changing production requirements instantly and perform duties differently in real time.

The EVS QJRB15-1 and QJRB30-1 models serve as excellent illustrations of how assembly robots will shape logistics and assembly line operations in the future by providing companies with the agility, speed, and accuracy required to succeed in the cutthroat market of today.

In summary

To sum up, the incorporation of assembly robots into smart logistics systems is revolutionizing how companies manage their supply chains and manufacturing processes. The QJRB15-1 and QJRB30-1 robots from EVS are at the forefront of automation for assembly activities because of their unmatched productivity, adaptability, and precision. These assembly robots save labor expenses, speed up production, and enhance product quality, making them indispensable instruments for contemporary industry. Assembly robots will become increasingly more important in the future as smart logistics develops to help businesses remain competitive and meet the expanding demands of the global market.

Arabic

Arabic Bulgarian

Bulgarian Czech

Czech Dutch

Dutch English

English Finnish

Finnish French

French Georgian

Georgian German

German Greek

Greek Hungarian

Hungarian Italian

Italian Japanese

Japanese Korean

Korean Lithuanian

Lithuanian Myanmar (Burmese)

Myanmar (Burmese) Persian

Persian Polish

Polish Portuguese

Portuguese Romanian

Romanian Russian

Russian Serbian

Serbian Slovak

Slovak Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese