Gear boxes: Increasing Robot Performance

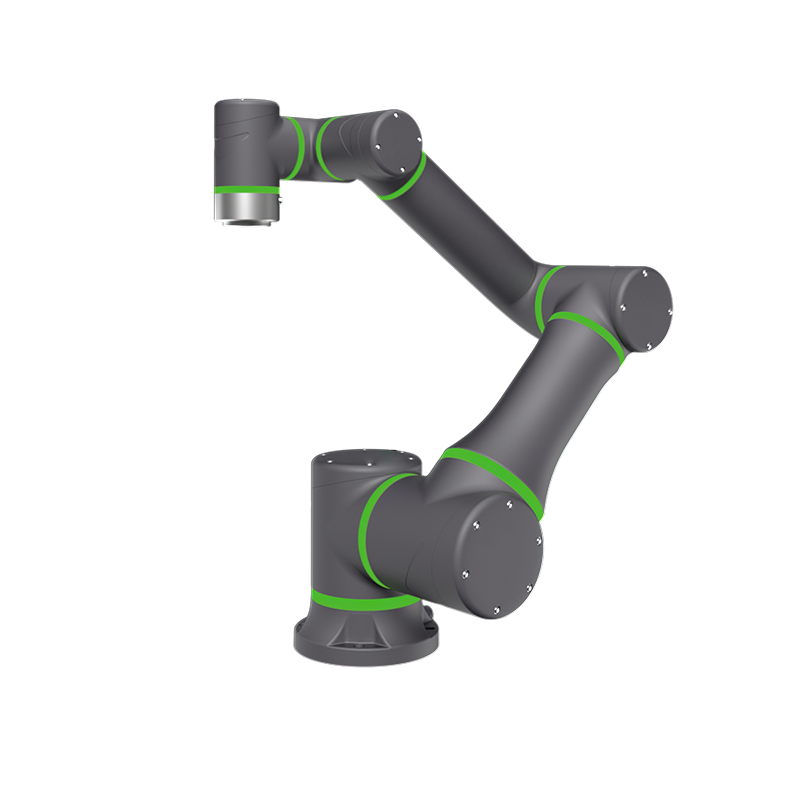

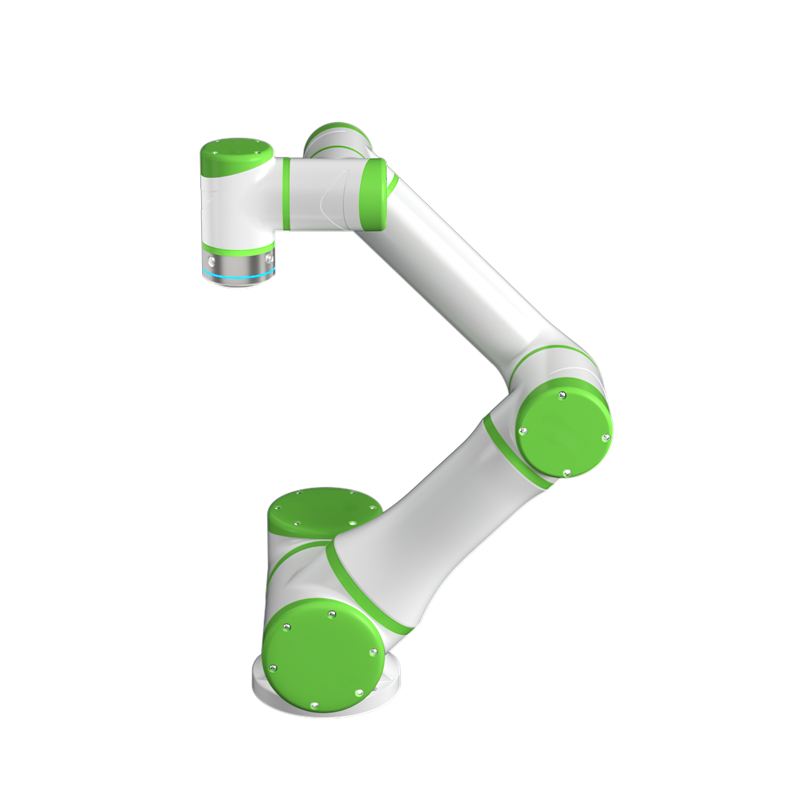

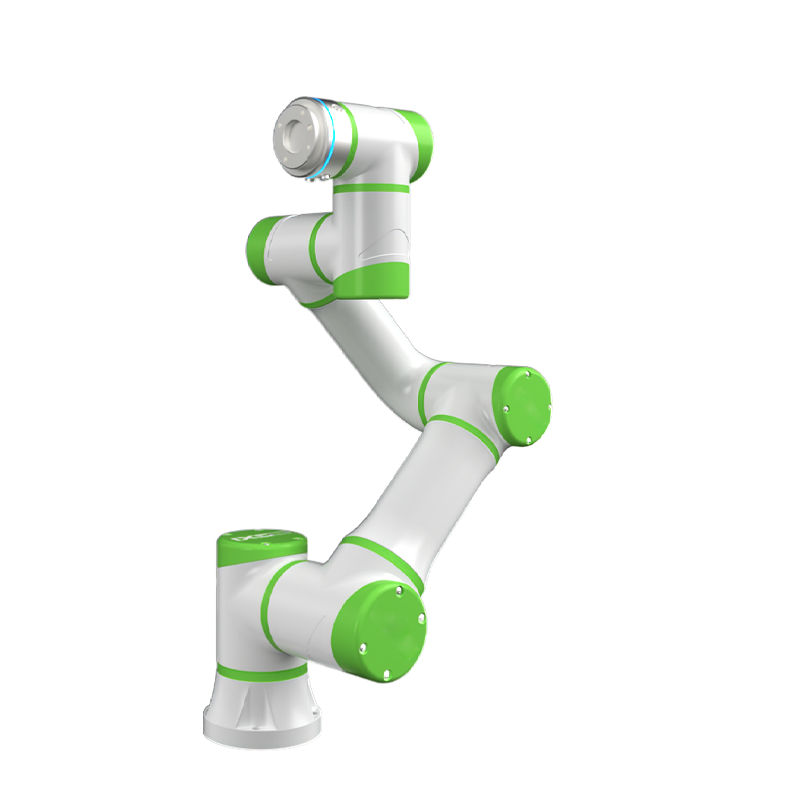

The interaction between gear boxes and six axis robots is essential for high-performance tasks in industrial automation. Advanced gear boxes govern the exact movements of six-axis robots, which perform intricate jobs. By controlling torque and speed, these gear boxes make sure the robots function smoothly across their six degrees of freedom. Six axis robots would not be able to perform the exact motions required in industries like aerospace and automotive manufacture without a high-quality gear box, which provides the required stability and control.

Control and Accuracy with Gear boxes

Six axis robots can reach a better level of accuracy by employing high-performance gear boxes. Robot motion is stabilized by gear boxes, which provide precise torque and speed control for a variety of applications. The torque management that the gear box provides is important to the precision of six axis robots, whether they are being assembled or are welding. Gear boxes increase system longevity and minimize wear on robotic components by maintaining smooth motion, which boosts productivity in high-demand production settings.

Boosting Efficiency with Six-Axis Robots

Six axis robots are crucial for increasing productivity in sectors that move quickly. These robots can move between duties with ease thanks to gear boxes, which guarantee that speed doesn’t come at the expense of accuracy. The gear box‘s management over this speed-accuracy balance guarantees that cycle times are kept to a minimum while product quality is maintained. The use of six axis robots with premium gear boxes is extremely advantageous for industries that require high throughput, such as packing and material handling.

Gear boxes and Hard Industrial Operations

Gear boxes are essential for maintaining stability during complicated, fast-paced movement operations like robotic welding or assembling. Even under different stress situations, the gear box in six axis robots makes sure that motions are steady and smooth. For sectors like electronics or aircraft that require a high degree of accuracy, this is crucial. Six axis robots can adjust to a variety of manufacturing needs thanks to gear boxes, which manage speed and torque without sacrificing accuracy or control.

Upcoming Developments in Gear box Technology

The function of gear boxes in improving six axis robots will increase as industry demands change. Future developments in gear box technology will provide more accurate control, giving robots more versatility to do ever-more-complex jobs. More robust and effective gear boxes will be produced using new materials and intelligent control systems, enabling six axis robots to operate at even greater levels. Robotic automation will continue to succeed in sectors all around the world because to this progress.

In conclusion, the cooperation between gear boxes and six axis robots

For contemporary industrial processes to be successful, six axis robots and gear boxes must work together. Six axis robots may perform well in high-demand conditions thanks to the control and accuracy provided by gear boxes. Gear boxes make it possible for these robots to carry out difficult jobs precisely and effectively by maximizing torque and speed. Integrating high-performance gear boxes will be essential to enabling six axis robots to reach their full potential across a range of sectors as automation develops.