Success in industrial welding processes depends on attaining efficiency and precision. A high-performance gear box and welding turntable together may transform productivity by guaranteeing smoother, more reliable welds for every application. In order to improve accessibility and accuracy during welding procedures, welding turntables are made to hold and spin workpieces. The performance of the turntable is increased by the installation of a gear box, which makes it possible for it to function with more stability and precision—two qualities that are crucial for demanding industrial welding jobs.

Comprehending Welding turntables and How They Work

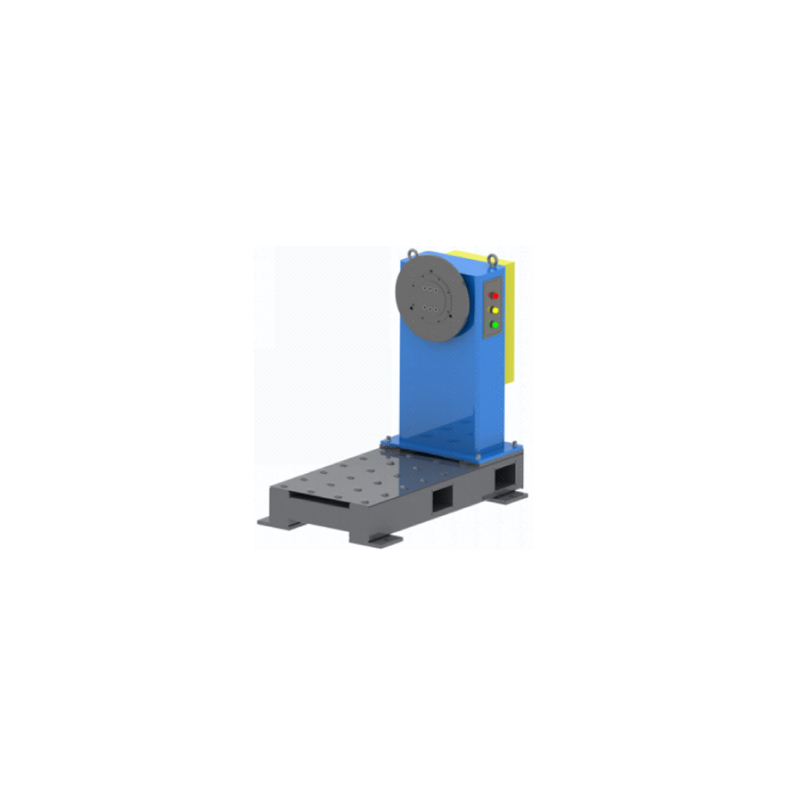

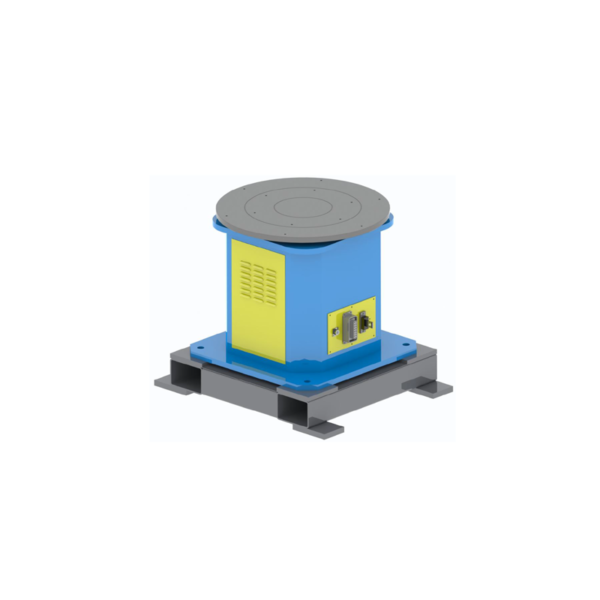

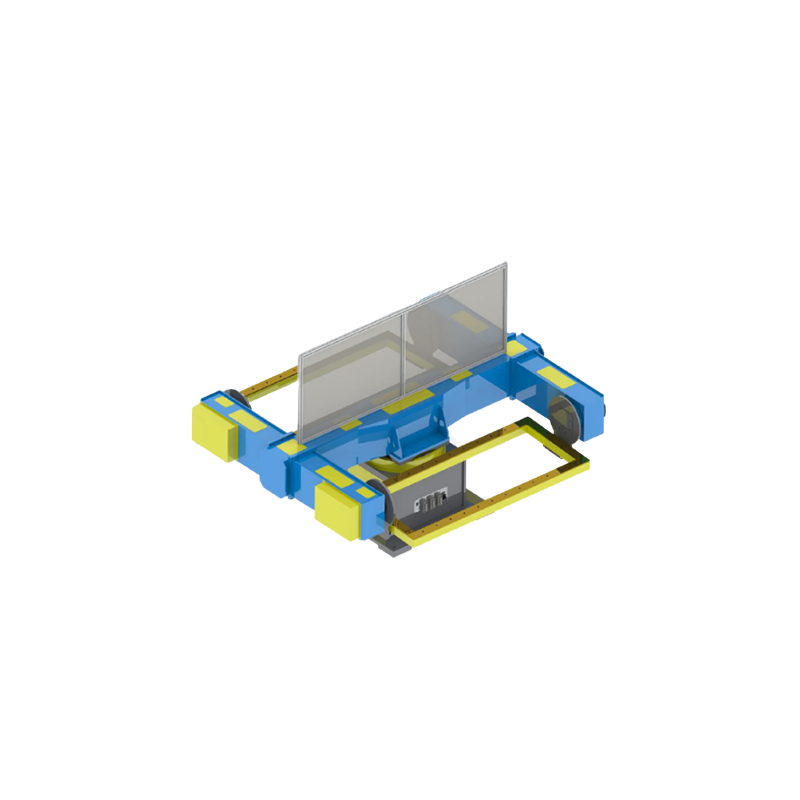

Workpieces can be held in the proper position by a revolving welding turntable, which enables welders to reach the joints from different angles without having to manually adjust them. This technology reduces the possibility of error and boosts production, making it extremely advantageous for both automated and manual welding procedures. Welding turntables are particularly useful for cylindrical or large pieces that are difficult to handle in an industrial setting. Turntables aid in preserving the best possible weld quality with their dependable rotating mechanism.

The Crucial Function of Gear boxes in Turntable Welding

An essential mechanical part for increasing the effectiveness of welding turntables is a gear box. The torque and speed needed to spin the workpiece precisely and steadily are converted from motor power. The gear box‘s accuracy guarantees that the welding turntable can spin smoothly, enabling the welder to maintain consistent weld quality all through the operation. Gear boxes may eliminate vibrations and undesirable movement, which can result in inconsistent welds, with the right torque management.

Getting Consistency and Accuracy in Welding Operations

The accuracy and uniformity of welding turntables with a gear box are greatly enhanced. Strict quality requirements must be met by welders in high-stakes sectors like aerospace and automobile manufacture. A gear box allows a welding turntable to spin the workpiece at the proper speed, resulting in a smooth motion that promotes uniform bead appearance and weld penetration. Reducing material waste and rework, which eventually results in better-quality products and cheaper manufacturing costs, depends on this accuracy.

Industrial Welding Automation and Efficiency Improvement

Automation in welding systems is further improved when a gear box and welding turntable are combined. Reliable and consistent rotation is essential for automated welding systems to ensure precision and repeatability. A gear box may be used to program welding turntables to revolve at specific intervals, removing the need for human adjustments and guaranteeing a consistent weld every time. Industrial operations are further streamlined by this automation, which not only increases production but also lowers labor costs by enabling workers to supervise many machines at once.

Utilization in Intense Industrial Environments

In sectors like shipbuilding, construction, or heavy machinery production that deal with big, heavy parts, the combination of welding turntables and gear boxes provides unmatched advantages. Stability, strength, and considerable weight handling are necessary for heavy-duty welding. A welding turntable‘s smooth, regulated rotation is made possible by a gear box, which provides the torque required to handle large pieces. With this configuration, even the heaviest parts may be welded with ease, cutting down on downtime and enhancing the process’s efficiency and safety.

In conclusion, gear boxes play a crucial role in welding turntable optimization.

Including a gear box in a welding turntable is a crucial tactic for streamlining industrial welding operations. The gear box offers the stability, torque, and speed control required to produce accurate and reliable welds, which raises output and reduces expenses. This combination expands the possibilities of welding systems for sectors that need high-quality welding of big or complicated parts, enabling improved automation, more efficiency, and better outcomes. For any industrial application seeking to increase accuracy and efficiency, welding turntables with gear boxes are a priceless tool, whether they are utilized for human welding operations or automated robotic systems.