Introduction

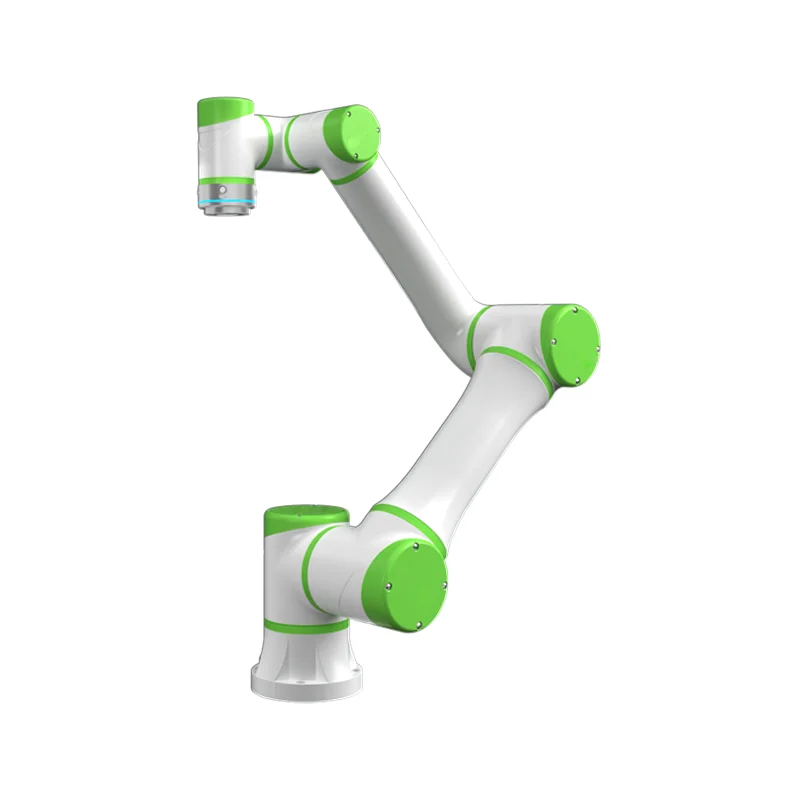

The modern industrial landscape is increasingly driven by innovations in robotics, where precision, efficiency, and adaptability are paramount. Among these innovations, six axis robots have emerged as pivotal components due to their versatility and advanced operational capabilities. These robots are complemented significantly by robot tracks, which provide the necessary mobility and stability for varied and complex industrial tasks. This article delves into the collaborative use of six axis robots and robot tracks, highlighting their roles, integration, and impact on industrial operations. A case in point is the 6kg payload, 917 mm reaching distance six axis collaborative robot, which epitomizes the fusion of high reliability and excellent performance. Engineered primarily for tasks like handling, palletizing, and arc welding, this robot excels in confined spaces and can liberate human workers from repetitive and hazardous environments.

Overview of Six Axis Robots

Technical Description and Capabilities

Six axis robots are distinguished by their flexibility and range of motion, which are crucial in complex automation processes. The model R6-093S, for instance, boasts an impressive array of features: it has a 917 mm armspan and a payload capacity of 6kg, suitable for various medium-duty tasks. Thanks to its six degrees of freedom, it can move and articulate more precisely and consistently than a human arm could. The robot’s ability to rotate all 360 degrees allows it to handle materials with remarkable accuracy and agility.

Applications in Industry

The application of six axis robots extends across various sectors, including automotive, electronics, food and beverage, and more. These robots are particularly effective in tasks that require high precision and repeatability such as pick and place, palletizing, and welding. For example, the QJRB180-1 universal robot can perform high-speed, high-precision tasks such as palletizing and packaging in industries like furniture and food and beverage. Its capacity to run continuously along a predetermined trajectory enhances productivity and reduces the chances of errors, showcasing the substantial benefits of six axis robots in modern manufacturing.

Understanding Robot Tracks

Functionality and Design

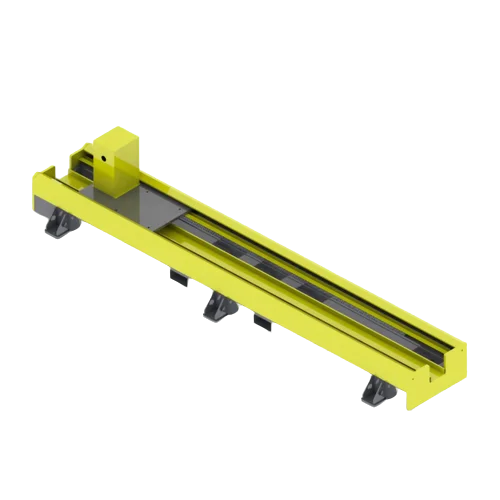

Robot tracks significantly extend the functionality of robots by enhancing their mobility and allowing them to operate over larger areas. The EVS Robot Track is a prime example of this technology. It utilizes high-quality reducers and gears to ensure smooth movement and stability, crucial for operations requiring precision. These tracks can be customized in terms of rated load and length, catering to specific industrial needs and enhancing the operational versatility of robots.

Applications and Performance

Robot tracks are employed in a wide range of applications, including welding, cutting, handling, machining, and painting. Their steadiness and accuracy are vital in settings where precise motion patterns are necessary, like assembly lines or complex machining jobs. Robot tracks increase the efficiency of robotic operations and broaden the range of tasks that can be automated by allowing robots to move with high accuracy along predetermined paths.

Integration of Six Axis Robots with Robot Tracks

Enhancing Operational Efficiency

Integrating six axis robots with robot tracks creates a synergy that enhances the operational efficiency of robotic systems. This combination allows for extended reach and mobility, increasing the robot’s ability to perform tasks over a larger area without sacrificing speed or precision. For instance, a six axis robot mounted on a track can perform sequential tasks along an assembly line more efficiently than stationary robots, reducing cycle times and increasing throughput.

Case Studies of Integrated Systems

Real-world implementations of integrated systems demonstrate their effectiveness. One such example involves a six axis robot combined with a robot track system designed for an automotive assembly line. This setup allows the robot to perform multiple tasks such as welding and parts assembly without the need for multiple stationary robots, significantly reducing the space required and increasing the flexibility of the production line.

Conclusion

With previously unheard-of levels of efficiency, precision, and flexibility in industrial operations, the combination of six axis robots and robot tracks represents a significant advancement in robotic technology. The function of six axis robots and robot track will only become more important as industries continue to develop and demand more complex and varied tasks from their robotic systems. In addition to improving manufacturing capabilities now available, these technologies open the door for upcoming breakthroughs that will further change the industrial landscape.

For industries looking to enhance their operational capabilities, the adoption of six axis robots and robot tracks offers a proven solution. Further exploration and consultation with industry experts can provide tailored insights and strategies to leverage these advanced technologies effectively.