Introduction

Within the dynamic realm of manufacturing technology, autonomous systems assume a critical function in augmenting accuracy and productivity in a multitude of sectors. Welding platforms and laser welding robots are prominent technologies that are significantly contributing to the modernization of welding operations. This article explores the interoperability and synergy between the Platform Two Axis Servo Positioner EVS-DWP-P series Welding turntables and the QJR6-1400H Laser welding robot, with a particular focus on how these two devices transform conventional welding operations.

A Comprehension of Laser Welding Robots

In robotic welding, the QJR6-1400H Laser Welding Robot exemplifies cutting-edge technology. A multiplicity of performance-enhancing features are incorporated, such as a joint gear grasp adjustment that facilitates precise control and a hollow joint support structure that simultaneously improves rigidity and flexibility. The noise reduction structure effectively mitigates operational sounds, rendering it well-suited for environments characterized by noise pollution. The robot’s repeat positioning accuracy is ±0.08mm, which enables it to manipulate a wide range of materials with remarkable precision, including carbon steel, stainless steel, aluminum, and copper. It has a payload capacity of 6kg and an armspan of 1456mm. In intricate manufacturing duties, the accuracy and versatility of laser welding robots, such as the QJR6-1400H, are indispensable for producing high-quality welds.

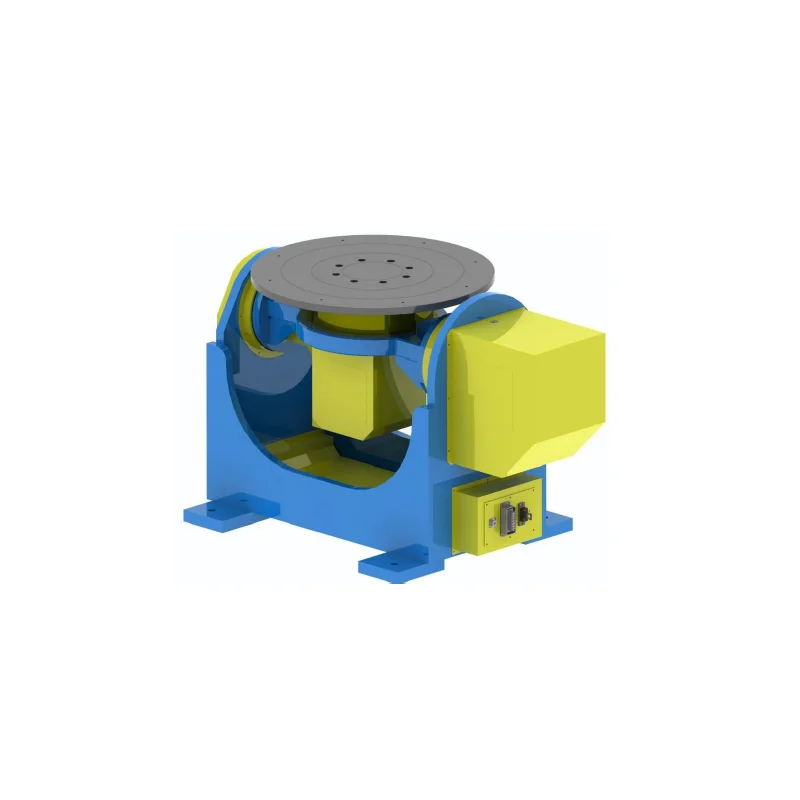

The Advantages and Functionality of Welding Turntables

The EVS-DWP-P series of Platform Two Axis Servo Positioners signifies a substantial progression in the field of welding turntable technology. The superior performance of these welding turntables is due to the fact that they consist of a sturdy welding frame, a gyration platform driven by an AC servo motor, and an RV precise reducer. The series comprises multiple models capable of managing burdens ranging from 200kg to 1000kg, while maintaining repeat positioning accuracies between ±0.10mm and ±0.20mm. The welding turntables’ adaptability, specifically in their capacity to rotate workpieces to their most advantageous positions, improves the effectiveness and caliber of welding procedures, rendering them a crucial element in contemporary manufacturing configurations.

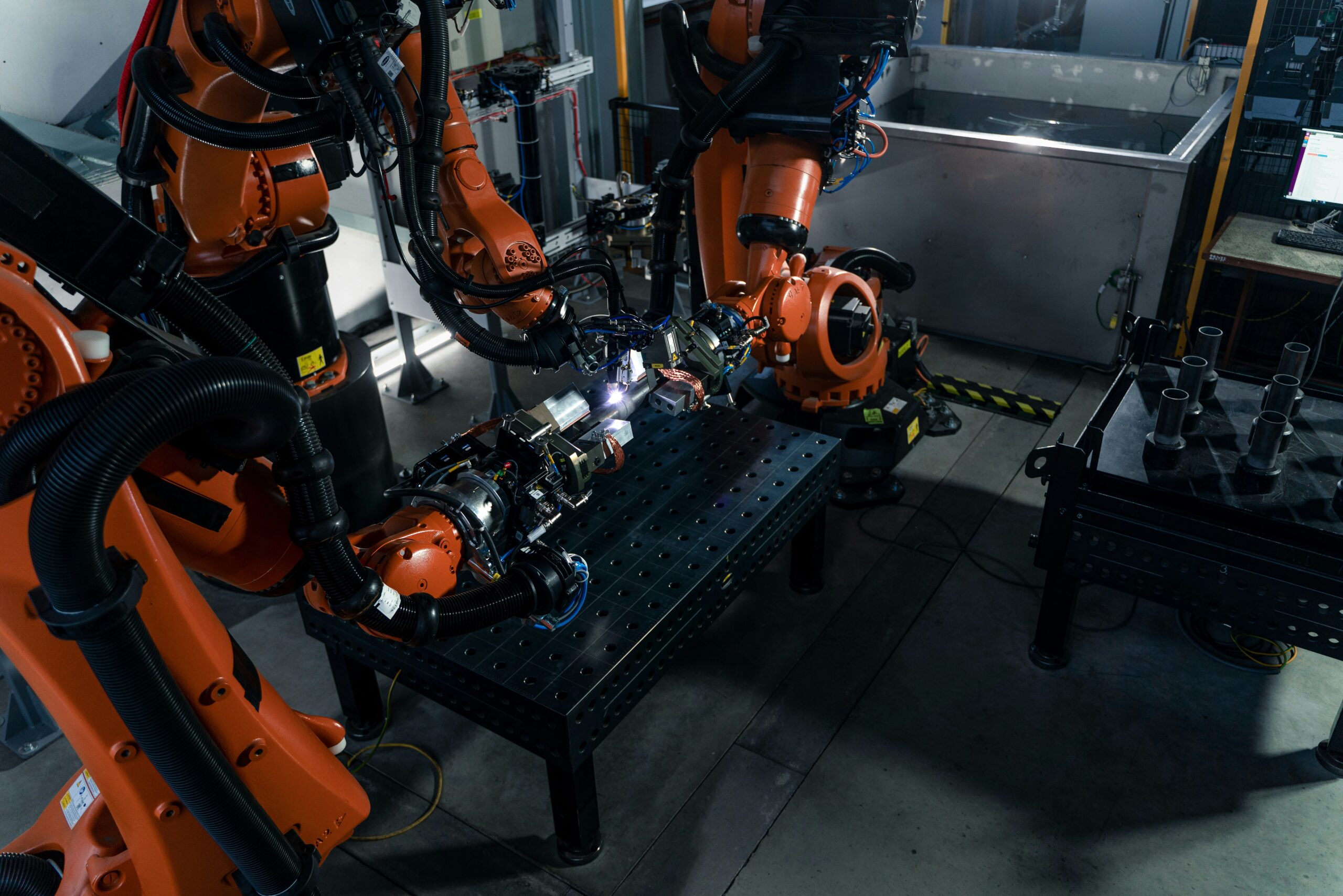

Welding Turntables and Laser Welding Robots Operating in Concert

A highly efficient welding system is produced by integrating the QJR6-1400H Laser welding robot with the EVS-DWP-P series Welding turntables. The combination of these factors enables the laser welding robot to execute its duties with enhanced precision and velocity, as the welding turntables ensure the ideal placement of workpieces. The effective collaboration between the welding gimbal and the robot guarantees that every weld is performed with impeccable depth and alignment, thereby substantially improving the quality of the welds and diminishing the need for labor-intensive manual adjustments. By means of this integration, the welding process is not only streamlined, but productivity is also increased and operational expenses are decreased.

Case Study: Implementation in the Manufacturing of Fitness Equipment

An instance that exemplifies the advantages of integrating welding platforms and laser welding robots is a recent undertaking in the fitness equipment manufacturing sector. The QJRH4-1 robots were utilized in conjunction with single-axis positioners to significantly enhance the quality and productivity of the welding processes in this endeavor. Coordination between the robotics and positioners improved the weld seams’ fluidity, stability, and tightness while also conserving space. The utilization of welding turntables in conjunction with the straightforward operation and high efficiency of the laser welding robots led to the development of automatic welding processes that exhibited a substantial improvement over conventional techniques.

An Examination in Comparison to Traditional Welding Systems

In contrast to traditional welding systems, the integration of welding platforms and laser welding robotics presents an array of unparalleled benefits. Conventional welding apparatus frequently depend on manual labor, a process that may exhibit inconsistencies and inefficiencies. The automated system, on the other hand, which consists of welding workstations and laser welding machines, minimizes human error, reduces labor expenses, and accelerates production. Moreover, the improved accuracy and uniformity of welds attained via these cutting-edge technologies result in decreased wastage and enhanced product quality, thereby establishing the superiority of welding turntable integration with laser welding robots in comparison to more traditional welding approaches.

Proximal Developments in Welding Technology

Ongoing technological advancements are anticipated to augment the functionalities of laser welding equipment and welding platforms, thereby bolstering the optimism surrounding the prospective trajectory of welding technology. It is anticipated that progress in the fields of machine learning and artificial intelligence will expedite the creation of welding robots that demonstrate improved levels of autonomy and intelligence. These robots would be outfitted with the capability to adjust parameters dynamically in accordance with sensory feedback. Additionally, manufacturers may be able to execute a broader spectrum of intricate and complex welding duties as a result of enhanced precision and adaptability brought about by developments in welding platform technology. Due to these technological advancements, the welding industry is poised to undergo a significant paradigm shift; they will expand the limits of present feasibility and create innovative prospects for advancements in manufacturing.

Conclusion

The integration of laser welding robots and welding platforms signifies a significant progression within the domain of manufacturing technology. By integrating these components, welding procedures are not only carried out with increased efficiency and excellence, but also the capacity of modern automation to fundamentally transform industrial processes is showcased. Without a doubt, as these technologies continue to be investigated and developed, autonomous systems will emerge that exceed every prior benchmark of complexity and effectiveness within the manufacturing industry. Undoubtedly, this will catapult productivity and innovation to all-time highs.