In 2025, robotic painting systems are revolutionizing industries by delivering unmatched precision and efficiency. These advanced machines are particularly transforming sectors like automotive and construction, where demand continues to grow. You can now achieve consistent quality while reducing labor costs and environmental impact. Autonomous painting robots operate tirelessly, ensuring uniform paint application and minimizing waste. With advancements in AI, these robots offer real-time monitoring and enhanced safety features. The competitive autonomous painting robot price makes them an attractive choice for businesses aiming to optimize production processes.

Key Takeaways

- Painting robots work with great accuracy and speed, helping industries like car-making and building.

- These robots cut down on worker costs and wasted materials, saving money over time.

- Smart tech like AI helps robots adjust to surfaces, giving smooth finishes always.

- Safety tools, like designs that prevent explosions and spot obstacles, keep workers and machines safe in risky areas.

- More people want these robots because they save time and are eco-friendly, making the market grow fast.

Overview of the Autonomous Painting Robot Market in 2025

Market Growth and Projections

The autonomous painting robot market has seen remarkable growth in recent years. By 2025, this market is expected to continue expanding due to increasing demand for efficient and precise painting solutions. Here are some key projections:

- The market size was valued at $1.2 billion in 2022.

- It is projected to reach $1.5 billion by 2024.

- By 2026, the market is estimated to grow to $2.5 billion.

- From 2024 to 2030, the market is expected to grow at a compound annual growth rate (CAGR) of 15.0%.

The Asia-Pacific region will likely experience the highest growth. Rapid industrialization and manufacturing activities in countries like China, Japan, and South Korea are driving this trend. The automotive sector, in particular, is fueling demand for robotic painting systems, while large-scale construction projects also contribute to this growth.

Key Industries Driving Demand

Several industries are driving the demand for commercial painting robots in 2025. These include:

- Automotive Industry: You can rely on robotic painting systems to achieve high-quality finishes and reduce defects in vehicle production.

- Construction Industry: These robots address challenges in manual painting by delivering faster and more consistent results on large surfaces.

- Aerospace Sector: Precision and quality are critical in aerospace, making autonomous painting robots an essential tool for this industry.

These sectors highlight the versatility and importance of robotic painting in modern manufacturing and infrastructure development.

Technological Innovations in Autonomous Painting Systems

Technological advancements have revolutionized commercial painting robots, making them more efficient and adaptable. Recent innovations include:

- AI and Machine Learning: Robots now analyze surfaces in real time and adjust techniques based on material, shape, and environmental conditions.

- Collaborative Robots (Cobots): These robots work alongside humans, improving efficiency and safety in painting tasks.

- Self-Learning Robots: These systems learn from their environment to optimize painting techniques over time.

The integration of Industry 4.0 technologies has further accelerated the adoption of these robots. By enhancing productivity and ensuring consistent quality, these innovations are transforming industries like automotive, construction, and aerospace.

| Innovation Type | Description |

|---|---|

| AI and Machine Learning | Integration of AI to enhance adaptability and precision in painting processes. |

| Collaborative Robots (Cobots) | Rise of cobots that work alongside humans to improve efficiency in painting tasks. |

| Self-Learning Robots | Development of robots that learn from their environment to optimize painting techniques. |

These advancements ensure that robotic painting systems remain at the forefront of industrial robots, meeting the evolving needs of various industries.

Key Features of Autonomous Painting Robots

Precision and Accuracy

Autonomous painting robots excel in delivering precise and accurate results. You can rely on these systems to follow intricate paths, ensuring even coverage across surfaces. This precision leads to a higher-quality finish, reducing the need for rework. Robots also control the thickness of paint layers with remarkable accuracy, which is essential for maintaining consistent results.

These robots achieve precision through advanced features like spatial awareness and real-time monitoring. Sensors and AI algorithms analyze their actions, ensuring uniform paint application. This reduces overspray and minimizes paint waste, saving costs while maintaining quality.

| Feature | Explanation |

|---|---|

| Precision and Accuracy | Robots follow intricate paths ensuring even coverage across surfaces. |

| Improved Quality Control | AI algorithms and sensors monitor actions in real-time for uniform paint jobs, reducing rework. |

| Spatial Awareness | Understanding position relative to surroundings allows for precise painting without overlaps. |

By controlling flow rates and air pressure, robotic painting systems ensure uniform layers with minimal overspray. This level of control makes them indispensable in industries like automotive and aerospace.

Speed and Efficiency

Commercial painting robots are designed to maximize speed and efficiency. These systems operate continuously, increasing throughput and reducing production times. Unlike human workers, robots maintain consistent performance without fatigue, ensuring high productivity levels.

You will notice significant cost savings with these robots. They lower operational costs by minimizing human error and reducing the need for skilled manual labor. Additionally, their ability to operate with minimal downtime enhances efficiency, making them a valuable asset in any production line.

- Precision ensures even coverage across surfaces.

- Consistency maintains high performance without fatigue.

- Speed increases throughput by reducing production times.

- Cost efficiency lowers operational costs by minimizing errors.

- Environmental benefits reduce waste and hazardous materials.

These features make robotic painting systems a game-changer in commercial painting, helping businesses achieve faster and more efficient operations.

AI and Machine Learning Capabilities

AI and machine learning have revolutionized the functionality of commercial painting robots. These technologies enable robots to learn from their environment and adapt to different surfaces. You can trust AI-powered robots to optimize painting processes in real time, ensuring the best results for every application.

AI-controlled robots use advanced techniques like deflectometry to detect variations in paintwork. This ensures optimal quality and process speed. They also analyze surfaces in real time, adjusting techniques based on material, shape, and environmental conditions. This adaptability makes them ideal for industries requiring high precision, such as automotive and aerospace.

- AI-powered robots learn from their environment to optimize processes.

- Deflectometry detects paintwork variations for better quality.

- Real-time analysis adjusts techniques for different surfaces.

These capabilities highlight the role of AI in the development of commercial painting robots, ensuring they remain at the forefront of industrial robots.

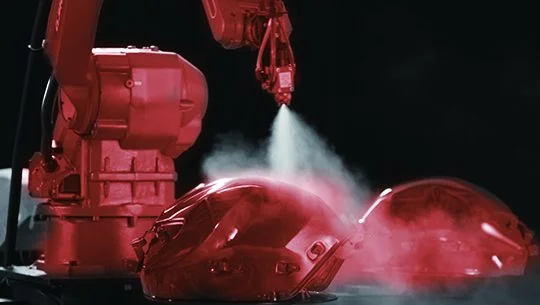

Safety and Explosion-Proof Features

Safety plays a critical role in the design of robotic painting systems. These machines often operate in environments where flammable materials, such as paint and solvents, are present. Explosion-proof features ensure that you can use these robots safely in hazardous conditions. Many models come with certifications that guarantee their ability to function without sparking or overheating, reducing the risk of accidents.

Advanced safety mechanisms also protect workers and equipment. Sensors detect obstacles and adjust the robot’s movements to avoid collisions. This feature minimizes the chances of damage to the robot or the surrounding workspace. Additionally, emergency stop functions allow you to halt operations instantly if an issue arises.

Explosion-proof designs often include sealed components and specialized coatings. These features prevent the entry of dust or liquids, ensuring the robot’s durability in harsh environments. For example, many robotic painting systems meet IP67 standards, which means they are resistant to water and dust. This level of protection makes them ideal for industries like automotive and aerospace, where safety and reliability are paramount.

By investing in a robotic painting system with robust safety features, you can ensure a secure and efficient work environment. These features not only protect your workforce but also enhance the longevity of your equipment, making them a valuable addition to any commercial painting operation.

Ease of Use and Maintenance

Ease of use is a key factor when choosing a robotic painting system. Modern designs prioritize user-friendly interfaces and intuitive controls. You can operate these robots with minimal training, thanks to features like non-teaching spray painting. This function allows the robot to mimic manual movements and automatically generate painting paths, simplifying the process for operators.

Maintenance is equally straightforward. Many robotic painting systems are built with durability in mind, reducing the need for frequent repairs. Components like sealed joints and explosion-proof designs protect the robot from wear and tear. This ensures consistent performance over time, even in demanding environments.

The following table highlights design elements that make these systems easy to use and maintain:

| Design Element | Explanation |

|---|---|

| Precision and Accuracy | Ensures even coverage across surfaces with high precision. |

| Consistency | Maintains uniform results across large production runs. |

| Speed | Operates faster than traditional methods, increasing throughput. |

| Enhanced Efficiency | Designed to work continuously, minimizing downtime. |

| Improved Quality Control | Uses sensors and AI for real-time monitoring, ensuring consistent paint jobs. |

| Reduced Labor Costs | Lowers the need for skilled manual labor, saving operational costs. |

| Environmental Benefits | Reduces paint overspray and waste, contributing to eco-friendly practices. |

These features make robotic painting systems a practical choice for commercial painting tasks. You can achieve high-quality results while minimizing operational challenges. By selecting a system with easy-to-use controls and low-maintenance requirements, you can focus on optimizing your production processes.

Comparison of Top Autonomous Painting Robots

QJAR Robotics Painting Robot

Features

The QJAR Robotics Painting Robot offers advanced features tailored for precision and efficiency. Its models, such as the QJR6-2700P and QJR20-1600, cater to different payload and reach requirements. These robots support multiple spraying methods, including gas spraying and electrostatic spraying. The explosion-proof design ensures safe operation in hazardous environments. The IP67 rating enhances durability, making it suitable for harsh conditions. Additionally, the non-teaching spray painting function simplifies operation by imitating manual movements and generating automatic trajectories.

Autonomous Painting Robot Price

QJAR Robotics provides competitive pricing for its painting robots. The cost varies depending on the model and its specifications, ensuring options for businesses of all sizes.

Unique Selling Points

QJAR Robotics stands out as the first Chinese brand to offer certified explosion-proof painting robots. Its refined wrist design minimizes vibrations, ensuring consistent results. The versatility in spraying methods and user-friendly operation makes it a top choice for commercial painting tasks.

YASKAWA Painting Robot

Features

YASKAWA Painting Robots are known for their high-speed performance and precision. These robots feature advanced motion control systems that ensure smooth and accurate paint application. They are designed for flexibility, making them suitable for various industries, including automotive and aerospace. The compact design allows for easy integration into existing production lines.

Autonomous Painting Robot Price

YASKAWA offers premium pricing for its painting robots, reflecting their advanced technology and reliability. While the cost may be higher, the long-term benefits in efficiency and quality make it a worthwhile investment.

Unique Selling Points

YASKAWA excels in delivering high-speed robotic painting solutions. Its compact design and advanced motion control systems provide unmatched precision. These features make it a preferred choice for industries requiring consistent and high-quality finishes.

Universal Robots Painting Robot

Features

The Universal Robots Painting Robot, particularly the RO1 model, combines powerful AI with an 18 kg payload capacity. Its intuitive no-code interface simplifies operation, making it accessible even for users with minimal technical expertise. This robot delivers exceptional performance in commercial painting applications.

Autonomous Painting Robot Price

The RO1 model is priced at half the cost of similar models, offering exceptional value. This affordability makes it an attractive option for businesses seeking cost-effective solutions.

Unique Selling Points

Universal Robots stands out for its affordability and ease of use. The no-code interface reduces the learning curve, while the powerful AI ensures optimal performance. These qualities make it a strong contender among top industrial brands in the robotic painting market.

Side-by-Side Comparison of Features and Prices

When comparing the top autonomous painting robots in 2025, you will notice significant differences in features and pricing. Each brand offers unique advantages tailored to specific needs, making it essential to evaluate them side by side. Below is a table summarizing the key features and price ranges of leading robotic painting systems:

| Brand | Model | Price Range | Key Features |

|---|---|---|---|

| Standard Bots | RO1 | Half the cost of similar models | Powerful AI, 18 kg payload, no-code interface |

| ABB | IRB 1100, IRB 1300 | High precision, varies by model | Reliability, precision for compact applications |

| FANUC | M-20iA/35M, LR Mate 200iD | Varies by model | Durability, extensive customization options |

| KUKA | KR QUANTEC, KR AGILUS | Varies by model | Flexibility and precision for diverse applications |

You can see that Standard Bots offers a highly affordable option with its RO1 model, which combines powerful AI and an intuitive no-code interface. ABB focuses on precision and reliability, making it ideal for compact applications. FANUC provides durable robots with extensive customization options, while KUKA excels in flexibility and precision for diverse tasks.

Pricing for robotic painting systems varies widely based on the model and features. Entry-level models typically start around $20,000, making them accessible for smaller businesses. Mid-range options range between $50,000 and $100,000, offering a balance of performance and cost. High-end robots, designed for advanced applications, can exceed $200,000. If you are looking for a more affordable solution, used robots often come at a comparable cost, with discounts of 30-50% compared to new models. However, you should also consider additional expenses like installation (10-20% of the robot’s price), maintenance, and operator training.

By comparing these options, you can identify the robotic painting system that best suits your needs. Whether you prioritize affordability, advanced features, or durability, the market offers a solution for every requirement.

Benefits of Autonomous Painting Systems

Cost Savings and ROI

Autonomous painting systems offer significant cost savings and an impressive return on investment (ROI). These systems reduce labor costs by automating tasks that traditionally require extensive manpower. For example, the U.S. Air Force saved 80% in labor costs by implementing robotic painting systems, cutting labor hours from 1,600 to just 300 per unit. Over time, this approach saved $8.8 million in maintenance costs, equating to $220,000 per aircraft.

You also benefit from reduced material waste. These systems apply coatings with precision, minimizing overspray and ensuring efficient material usage. The Air Force reported saving $40,000 per aircraft due to better material utilization. While the initial investment in these systems may seem high, the long-term savings in labor, materials, and operational efficiency make them a cost-effective choice for businesses aiming to stay competitive.

Enhanced Efficiency and Productivity

Autonomous painting systems excel in boosting productivity. Unlike human workers, these systems operate continuously without fatigue, significantly increasing throughput. Their precision minimizes paint waste, making the process more cost-effective. Advanced technologies, like ABB’s PixelPaint, eliminate the need for conventional spray valves, reducing overspray and cutting paint loss by 20%-30%.

You can also benefit from faster setup and operation. Self-learning machines reduce the need for extensive offline programming. Robots can learn tasks in seconds, allowing for quicker deployment. A Dutch company demonstrated this efficiency by introducing a robotic solution that reduced task turnaround times by up to 60%. These features make autonomous painting systems indispensable for industries seeking to optimize production.

Improved Safety and Reduced Risks

Safety is a critical advantage of autonomous painting systems. These systems protect workers by reducing exposure to hazardous chemicals. Collision detection and prevention features enhance operational safety, ensuring smooth and secure operations.

You can also rely on these systems for precise paint application. By controlling flow rates and air pressure, they minimize the risk of accidents caused by overspray or uneven coatings. These safety improvements make autonomous painting systems a reliable choice for industries where worker safety and precision are paramount.

Consistent and High-Quality Results

Autonomous painting systems deliver consistent and high-quality results across various applications. These robots use advanced technologies to ensure precision and reliability in every task. You can trust them to maintain uniformity, even in complex or large-scale projects.

One key factor is their ability to adapt to different geometries. Robots scan the surface and derive motions based on the part’s shape. This adaptability ensures even paint coverage, regardless of the surface’s complexity. Additionally, a physics-based model validates paint deposition before execution. This step enhances quality control by identifying potential issues early.

| Principle | Description |

|---|---|

| Automation to the part | Robotic motions are derived from the scanned geometry of the part. |

| Physics properties | A model captures paint deposition to validate operations before execution. |

| Simulated defect generation | Simulation creates synthetic data for training inspection models. |

These systems also operate continuously without fatigue. This feature increases productivity while maintaining consistent performance. By minimizing human involvement, they reduce exposure to harmful substances, creating a safer work environment. Their precision in application minimizes paint waste, making the process both cost-effective and environmentally friendly.

For example, PaintJet’s semi-autonomous system uses advanced imaging to prepare surfaces and apply sanding, primer, and paint with high precision. AI integration predicts the maintenance lifecycle of the finish, ensuring long-lasting quality. This combination of imaging and AI guarantees superior results in every application.

By investing in autonomous painting systems, you can achieve flawless finishes with minimal effort. These robots ensure that every surface receives the same level of care and attention, delivering results that meet the highest standards of quality.

Future Trends in Autonomous Painting Robots

Integration with IoT and Smart Manufacturing

The integration of IoT and smart manufacturing is reshaping the future of autonomous painting robots. These technologies allow you to connect robots with other devices in your production line. This connectivity enables real-time data sharing, improving efficiency and reducing downtime. For example, IoT sensors can monitor paint levels and alert you when refills are needed, ensuring uninterrupted operations.

Smart manufacturing systems also enhance quality control. Robots equipped with IoT capabilities can analyze data from previous tasks to optimize their performance. This ensures consistent results across all projects. By adopting these technologies, you can streamline your processes and stay competitive in a rapidly evolving market.

Advancements in AI and Robotics

Advancements in AI and robotics are driving the development of smarter and more efficient painting robots. These innovations allow robots to adapt to complex surfaces and deliver precise results. For instance, AI-powered robots can analyze surfaces in real time and adjust their techniques to suit different materials. This adaptability ensures high-quality finishes every time.

Several key advancements are shaping this field:

- Automation and robotics are evolving rapidly, offering vast potential for future improvements.

- AI and 3D printing are being incorporated into robotic painting technology.

- Sustainable practices are becoming a focus, reducing waste and emissions in painting processes.

| Advancement Type | Description |

|---|---|

| AI and Machine Learning | Robots analyze surfaces in real time and adjust techniques accordingly. |

| Collaborative Robots (Cobots) | Cobots enhance efficiency and adaptability in painting processes. |

| Sustainable Practices | Focus on reducing waste and emissions in painting processes. |

These advancements highlight the ongoing development of robotic painting systems, ensuring they remain at the forefront of industrial innovation.

Expansion into Emerging Industries

Emerging industries are increasingly adopting autonomous painting robots to meet their unique needs. The automotive industry continues to lead this market, focusing on efficiency and high-quality finishes. Construction is also becoming a significant player, using these robots for large-scale projects that demand consistent results.

These robots improve worker safety by reducing the need for human labor in hazardous environments. For example, they can handle tasks involving toxic paints or hard-to-reach areas, minimizing risks for your workforce. As more industries recognize these benefits, the demand for robotic painting systems will continue to grow, driving further development in this market.

Challenges and Opportunities in the Market

The autonomous painting robot market in 2025 presents both challenges and opportunities. Understanding these factors can help you make informed decisions when adopting this technology.

Challenges

You may encounter several hurdles when integrating autonomous painting robots into your operations. These challenges include:

- High Initial Costs: Advanced technologies require significant investment. This can make it difficult for smaller businesses to adopt these systems.

- Complex Programming and Maintenance: Operating these robots often demands specialized knowledge. You may need to invest in training or hire skilled technicians.

- Regulatory Compliance: Safety and environmental standards vary across regions. Meeting these regulations can increase costs and complicate implementation.

Tip: To overcome these challenges, consider partnering with experienced vendors who offer training and support. This can simplify the adoption process and reduce long-term costs.

Opportunities

Despite the challenges, the market offers exciting opportunities for growth and innovation. Autonomous painting robots can open doors to new applications and industries. Key opportunities include:

- Emerging Markets: Expanding into sectors like construction and infrastructure development can help you tap into growing demand.

- Hazardous Environments: These robots excel in dangerous settings, such as offshore platforms in the oil and gas industry. Their ability to operate safely in such conditions makes them invaluable.

| Opportunity Type | Description |

|---|---|

| Emerging Markets | Growth potential in construction and infrastructure projects. |

| Hazardous Environments | Safe operation in risky areas like oil rigs or chemical plants. |

By addressing challenges and leveraging opportunities, you can maximize the benefits of autonomous painting robots. These systems not only enhance efficiency but also position your business for future success.

Autonomous painting robots in 2025 bring cutting-edge technology to industries like automotive, aerospace, and construction. These robots deliver precision, speed, and cost efficiency, making them essential for modern manufacturing. You can rely on their AI-driven capabilities to ensure consistent quality while reducing waste and operational costs.

Key takeaways from the comparison include:

- Precision and Accuracy: Robots follow intricate paths for even coverage.

- Consistency: They maintain uniform results without fatigue.

- Sustainability: Reduced overspray and emissions support greener practices.

- Technological Integration: AI and machine learning enhance adaptability.

| Key Takeaway | Description |

|---|---|

| Adoption in Industries | Widely used in automotive, aerospace, and construction for efficiency. |

| Market Drivers | Automation demand and the need for consistent quality drive growth. |

| Sustainability Shift | Robots minimize waste and emissions, aligning with eco-friendly goals. |

As technology evolves, these robots will continue to revolutionize industries, offering even greater benefits and opportunities for innovation.

FAQ

What industries benefit the most from autonomous painting robots?

Autonomous painting robots excel in industries like automotive, aerospace, and construction. You can use them to achieve consistent finishes, reduce labor costs, and improve safety. These robots also adapt well to manufacturing sectors requiring precision and efficiency.

How do autonomous painting robots ensure safety in hazardous environments?

These robots feature explosion-proof designs and advanced sensors. You can rely on them to operate safely around flammable materials. Emergency stop functions and obstacle detection further enhance safety, protecting both workers and equipment.

Are autonomous painting robots difficult to operate?

Modern painting robots prioritize ease of use. Many models include intuitive interfaces and non-teaching functions. You can operate them with minimal training, making them accessible even for those with limited technical expertise.

What is the typical price range for autonomous painting robots?

Prices vary based on features and specifications. Entry-level models start around $20,000. Mid-range options cost between $50,000 and $100,000. High-end robots exceed $200,000. You should also consider additional costs like installation and maintenance.

How do these robots improve environmental sustainability?

Autonomous painting robots reduce paint waste through precise application. You can minimize overspray and emissions, aligning your operations with eco-friendly practices. This efficiency also lowers material costs, benefiting both your business and the environment.