The way industries handle automation is changing as a result of the integration of six axis robots into robotics in logistics. These robots increase overall efficiency by providing unmatched flexibility and precision. The 6 kg Payload model and the 12 kg Payload model, in particular, are EVS’s collaborative six axis robots that are specifically made to simplify logistical operations. These sophisticated robots are ideal for selecting, sorting, and moving goods across huge warehouses. Six axis robots can operate smoothly with human workers in logistical environments due to their collaboration characteristics, increasing efficiency and safety.

Six axis robots’ Potential in Logistics

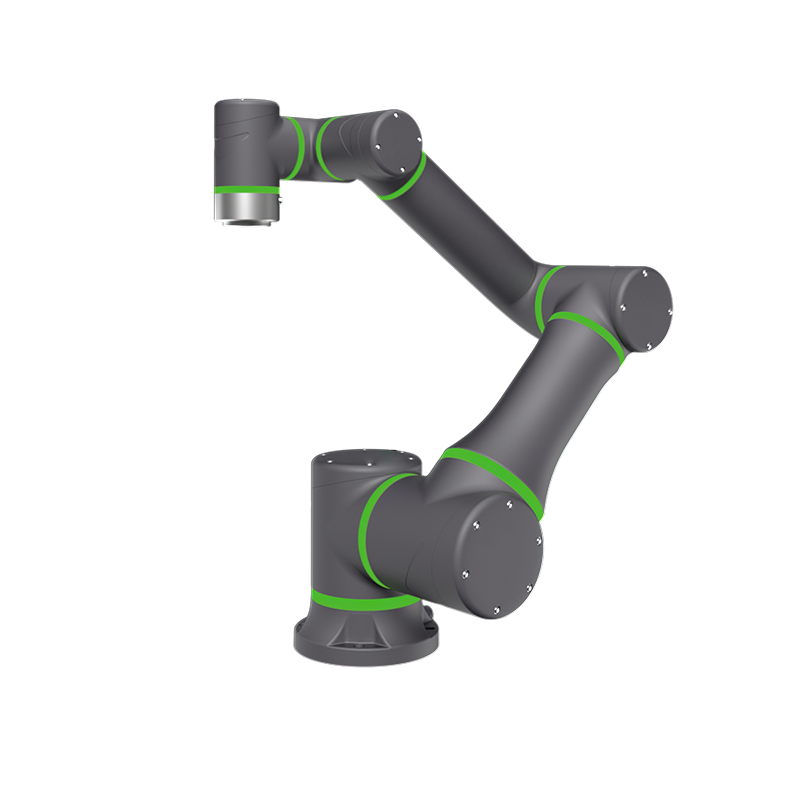

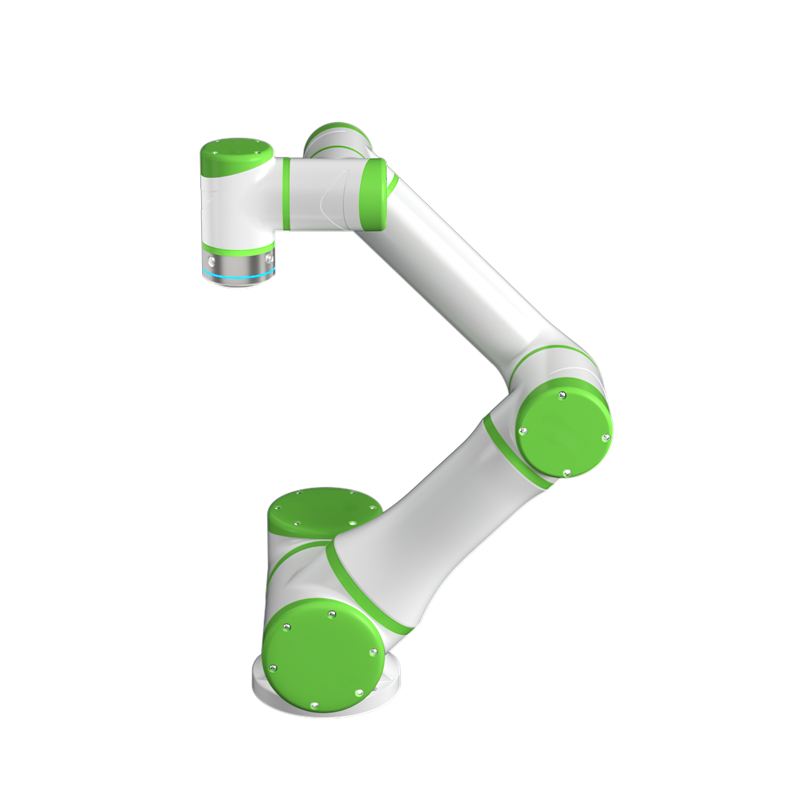

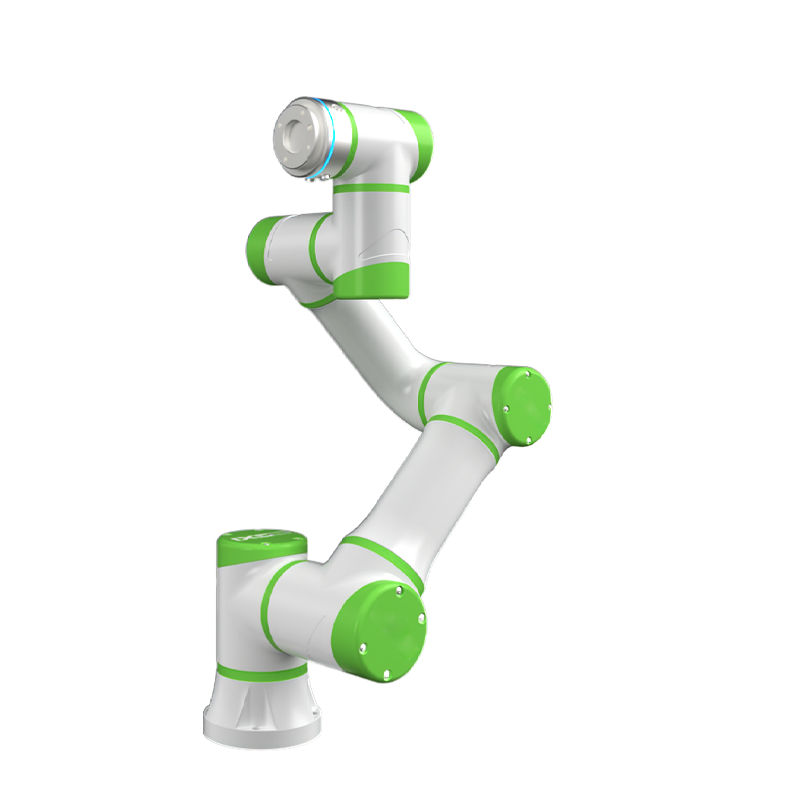

Because of their extensive range of motion, six axis robots are unique in robotics in logistics. These six-axis rotating robots are capable of precise performance of intricate jobs. This versatility makes robotics in logistics more capable of handling repetitive and varied jobs. An excellent example is the 6kg Payload Six-Axis Collaborative Robot from EVS, which has a 917mm reach and can do light duties like product picking and sorting in busy settings. For organizations looking to maximize logistical operations, six axis robots are essential due to their degree of precision.

Due to their ability to do jobs quicker and more reliably than human workers, six axis robots significantly minimize human error in robotics in logistics. Automating complicated and repetitive processes improves accuracy and lowers the risk of expensive errors in the logistics process. Warehouse and distribution facilities may operate much more efficiently thanks to the deployment of these robots, which can handle anything from order fulfillment to incoming shipments at various points of the logistics chain.

Six-Axis Robots: Adaptability and Flexibility

One of the main factors contributing to the success of six axis robots in logistics robotics is their versatility. They may function in a range of settings, including expansive distribution centers and tiny warehouses. With a 1300mm reach, EVS’s 12kg Payload Six-Axis Collaborative Robot is built for more demanding jobs. This strategy ensures that logistics operations may be increased as needed by offering more flexibility in handling larger commodities. In businesses where product demand and operations are subject to sudden changes, six axis robots are indispensable.

Six axis robots‘ capacity to carry out intricate activities including palletizing, sorting, and transporting enables enterprises to stay competitive in the field of robotics in logistics. These robots are highly flexible in hectic settings since they are simple to reprogramme to suit various duties. This flexibility guarantees that companies utilizing six axis robots may effectively address shifting client needs and supply chain difficulties.

Increasing Logistics Efficiency with Six-Axis Robots

Six axis robots play a major role in enhancing efficiency, which is a critical feature of robotics in logistics. These robots shorten the time and effort needed to finish logistical operations by automating repetitive tasks. The 6 kilogram and 12 kg payloads of EVS Six-Axis Collaborative Robots are made to work continuously without requiring regular supervision from humans. This improves throughput and lowers labor expenses, improving the efficiency of logistical operations.

Six axis robots speed up and improve the precision of logistical operations by simplifying jobs like picking, packaging, and sorting. By using these robots, the danger of human mistake in robotics in logistics is reduced, increasing efficiency. Businesses are able to fulfill orders from customers faster because to this boost in efficiency, which raises customer satisfaction and lowers total operating expenses.

Human-Robot Collaboration with Six-Axis Robots in Logistics

The capacity of six axis robots to securely interact with human workers is another important advantage in the field of robotics in logistics. These cooperative robots, or cobots, are made with cutting-edge safety measures that let them work side by side with people without endangering them. The six-axis collaborative robots from EVS, weighing six kg and twelve kg, each include safety features that sense human presence and modify their motions accordingly.

Humans and six axis robots work together to enhance operations in logistics robotics. While six axis robots conduct monotonous, high-precision labor, human workers may concentrate on more strategic tasks. This kind of cooperation increases output, lowers the number of workplace accidents, and improves overall job satisfaction. The coexistence of robots and humans at work guarantees a productive and well-balanced workplace where all parties may prosper.

Six axis robots: The Future of Logistics

The development of six axis robots is critical to the future of robotics in logistics. It is anticipated that these robots will become more and more crucial in automating logistical procedures, such as shipping and inventory control. The cutting-edge six axis robots from EVS will keep developing, providing even greater flexibility, accuracy, and cooperative capacities. These robots will probably become even smarter as a result of the integration of machine learning and artificial intelligence, giving them the ability to instantly adjust to shifting logistics requirements.

The intricacy of logistics operations will amplify the demand for robust and efficient automation solutions, such six axis robots. Businesses who buy these robots will be better equipped to handle supply chains, satisfy the demands of an ever-demanding customer base, and remain competitive. It appears that six axis robots will lead the prospective robotics in logistics transition.

In summary

Last but not least, six axis robots are transforming robotics in logistics by providing unmatched accuracy, adaptability, and efficiency. Leading the way are EVS’s 6 kg and 12 kg Payload Six-Axis Collaborative Robots, which give logistics companies the instruments they need to maximize productivity. Six axis robots are essential in contemporary logistical operations because to their mix of sophisticated mobility capabilities, versatility, and safety features. Businesses may use this technology to improve efficiency, cut expenses, and maintain an advantage in a market that is becoming more and more competitive.