An Overview of Turntables and Welding positioners

In industrial welding, accuracy and efficiency are essential. The employment of welding turntables and positioners is necessary to achieve these goals. EVS provides cutting edge solutions with its Platform Two-Axis Servo welding turntables and Single Axis Head and Tail Stock welding positioners. The precision, efficiency, and reduction of manual work are all increased by these welding positioners and welding turntables. This article examines the characteristics, advantages, and potential revolutionary changes this state-of-the-art technology may bring to your welding methods.

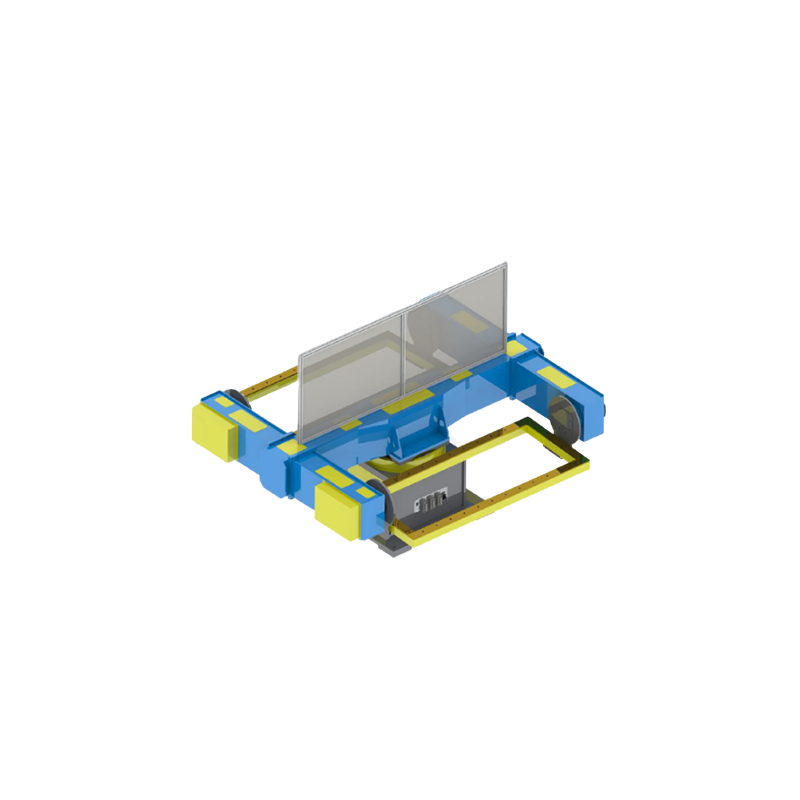

The Single Axis Head and Tail Stock Welding Positioner’s Features

EVS-SWP-ZW, a single axis head and tail stock welding positioner, offers control and accuracy. The welding turntable is excellent, mainly because of its single axis rotation capability. Because it is the best choice for handling heavy products, it has many models with 500, 800 and 1200 kg load capacity. It has excellent performance in accuracy and stability. The welding positioner has been easy to adjust in long-term use and is suitable for various welding applications. The solid design ensures its durability and stable performance. Of course, they are all very outstanding and excellent products.

Further Details:

carries 500, 800, and 1200 kg of weight.

Rotation: For exact control, use a single axis.

Adjustability: Simple adjustments allow for a wide range of applications.

Construction: Sturdy materials meant to last.

Support: For balanced placement, the head and tail stocks.

The Single Axis Head and Tail Stock Welding Positioner’s Advantages

The Single Axis Head and Tail Stock Welding Positioner has a lot of advantages. By improving accuracy, this welding turntable guarantees superior welds. By eliminating manual work, welding positioners raise output and efficiency. For managing big workpieces, the welding turntable offers stability and control. The sophisticated features of this welding positioner guarantee reliable operation. Businesses who use this welding turntable can significantly increase the quality of their welds and operating efficiency. Modern welding procedures need the use of EVS welding positioners.

Further Advantages:

Precision: Guarantees excellent welding.

Productivity: Lowers manual work while raising output.

Stability: Offers command over large, weighty components.

Performance: Dependable and steady operation.

Efficiency: Improves the quality of the weld and operational effectiveness.

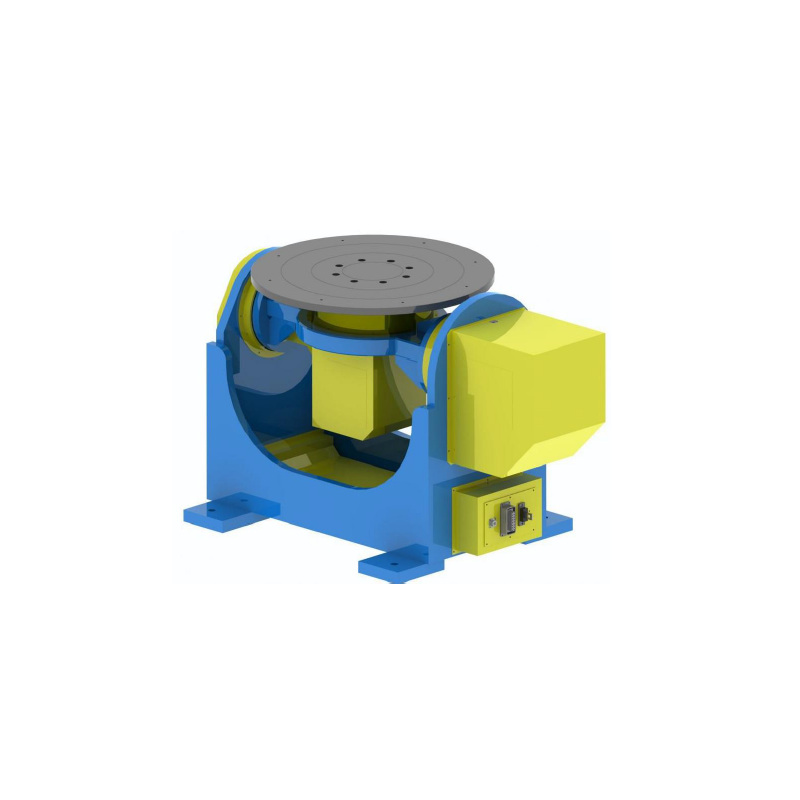

Features of the Two-Axis Servo Positioner Platform

Increased precision and flexibility are offered by the Platform Two-Axis Servo welding turntable (EVS-DWP-P). The two-axis rotation of this welding positioner facilitates difficult welding processes. It guarantees accurate control and is offered in models that support loads of 200 kg, 500 kg, and 1000 kg. Smooth and precise movements are made possible by the servo motors built into this welding turntable. It is appropriate for a range of industrial applications because of its sturdy design, which guarantees stability and dependability. For jobs demanding extreme flexibility and precision, the welding positioner is perfect.

Further Details:

carries 200, 500, and 1000 kg of weight.

Rotation: Two axes for intricate motions.

Servo motors: accurate and fluid control.

Building: Sturdy construction for stability.

Applications: Fit for intricate jobs including welding.

Advantages of the Two-Axis Servo Positioning Platform

The Two-Axis Servo welding turntable from Platform has several benefits. This welding positioner improves accuracy, guaranteeing a strong weld. Turntables that are welded require less manual labor, which boosts efficiency and production. For managing complicated workpieces, this welding positioner’s two-axis rotation offers flexibility and control. The sophisticated features of this welding turntable guarantee reliable functioning. Businesses using this welding positioner can enhance the quality of their welds and operating efficiency significantly. For contemporary welding processes, EVS welding turntables are essential.

Further Advantages:

Precision: Guarantees excellent welding.

Productivity: Lowers manual work while raising output.

Adaptability: Two-axis rotation for intricate duties.

Performance: Dependable and steady operation.

Efficiency: Improves the quality of the weld and operational effectiveness.

Utilizations of EVS Welding turntables and Positioners

Versatile instruments appropriate for a range of applications include EVS welding positioners and welding turntables. They are perfect for sectors including heavy machinery, automotive, and aerospace that demand exact workpiece placement. When working with cylindrical products, welding positioners come in handy since they provide consistent welds. Welding turntables offer flexibility and control, making them ideal for intricate welding jobs. Additionally, in production processes where repetitive welding operations are necessary, these instruments are employed. Modern industrial applications cannot function without the adaptability of EVS welding positioners and welding turntables.

Other Uses:

The automotive industry uses precision welding to join car parts.

Superb welds for aviation components are used in the aerospace industry.

Large and heavy workpieces are handled by heavy machinery.

In manufacturing, welding tasks must be repeated to ensure constant quality.

Expanding Welding Activities Precision and Efficacy

Integrating EVS welding positioners with welding turntables improves welding operations’ precision and efficiency significantly. These tools ensure effective welding by precisely placing the workpiece. Because welding positioners don’t require human modifications, they boost production and reduce the chance of errors. Welding turntables provide stability and control while handling large and complex workpieces. These welding positioners and welding turntables have advanced features that ensure smooth and dependable operation. By using EVS welding positioners and welding turntables, industries may increase the quality of their welds and their operating efficiency.

Further Improvements:

Precision placement for superior welding is known as accuracy.

Productivity: Enhanced effectiveness by minimizing manual adjustments.

Control: Stability in manipulating intricate workpieces.

Consistency: Dependable and easy to use.

Quality: Higher weld quality and more effective operations.

In summary

In summary, EVS welding positioners and welding turntables are crucial equipment for improving welding processes. Cutting-edge features that increase accuracy, output, and efficiency are included in both the Single Axis Head and Tail Stock welding positioner and the Platform Two-Axis Servo welding turntable. To guarantee the finest possible welds, our welding positioners and welding turntables offer the stability and control required. Weld quality and operating efficiency may be significantly increased by businesses using EVS welding positioners and welding turntables. Make an instant investment in EVS welding positioners and welding turntables to improve your welding processes and maintain your market edge.

Visit the following product pages for more specific details about these items:

Two-Axis Servo Positioner on Platform with Single Axis Head and Tail Stock Welding Positioner (EVS-DWP-P)

Invest in EVS welding positioners and welding turntables today to increase the accuracy and productivity of your welding.