“EVS” Intelligent logistics system integration

We focus on the

- Intelligent manufacturing field intelligent software as the core of the in-factory logistics integrated solutions

- Comprehensive solution for intelligent storage and intelligent order performance in the warehousing and distribution field

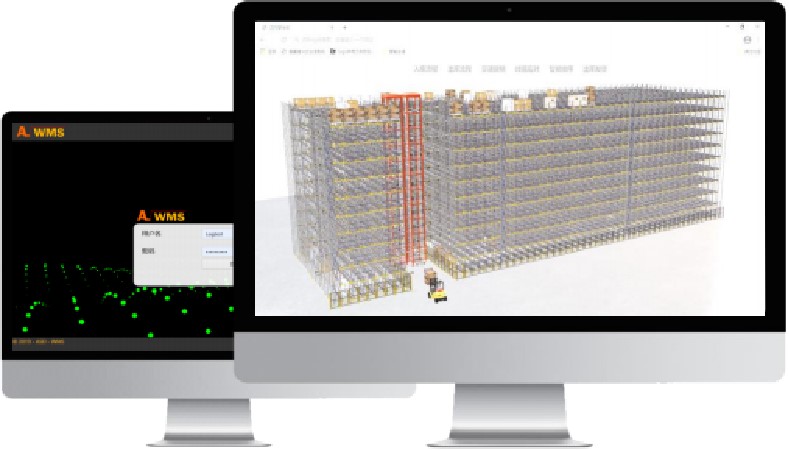

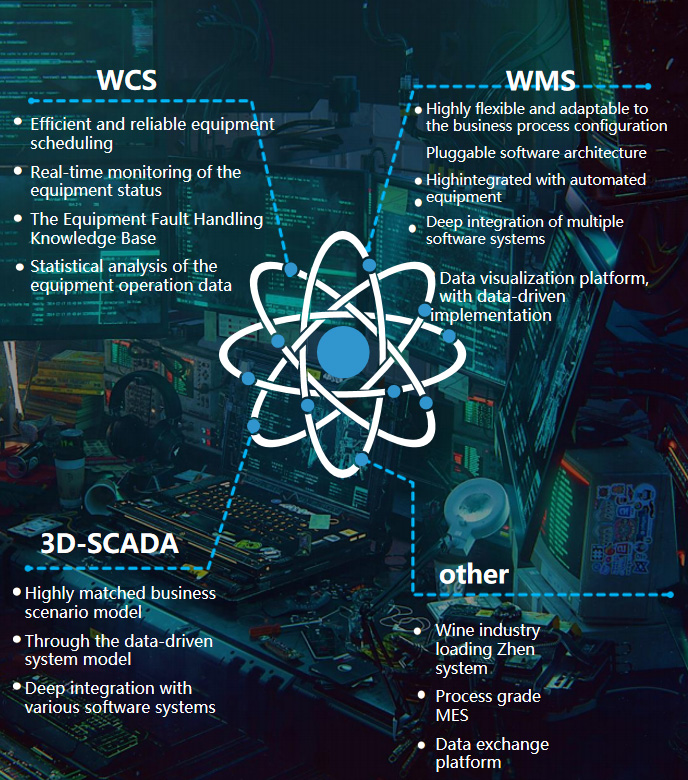

Logistics software products

The pursuit of excellence, no end

- We Deep cultivation in the industry for many years, focusing on providing excellence

- Intelligent logistics solutions and services

- Smart Warehoue Automation Robot Series

Logistics software products

Industrial robot

- Auto-cache the library

- Mixing stack

- Voluntarily select

- Multielement apply

AGV apply

- Unmanned forklift

- Mons for sorting

Delivery system

- Conveyor

- RGV

- Sorting machine

Intelligent and dense, set storage

- Two to Shuttle board

- A four-way shuttle car

- Intelligence counter

WMS system

- LES logistics carry out

- Be in motion and do business data analyse

- Dynamic depot Position distribution

WCS system

- SCADA

- Dynamic road Radial planning

- Equipment predictability maintenance

3D-SCADA

- 3D visualization

- Dispersed simulation

Other

- Wine industry Dress Zhen

- Process level MES

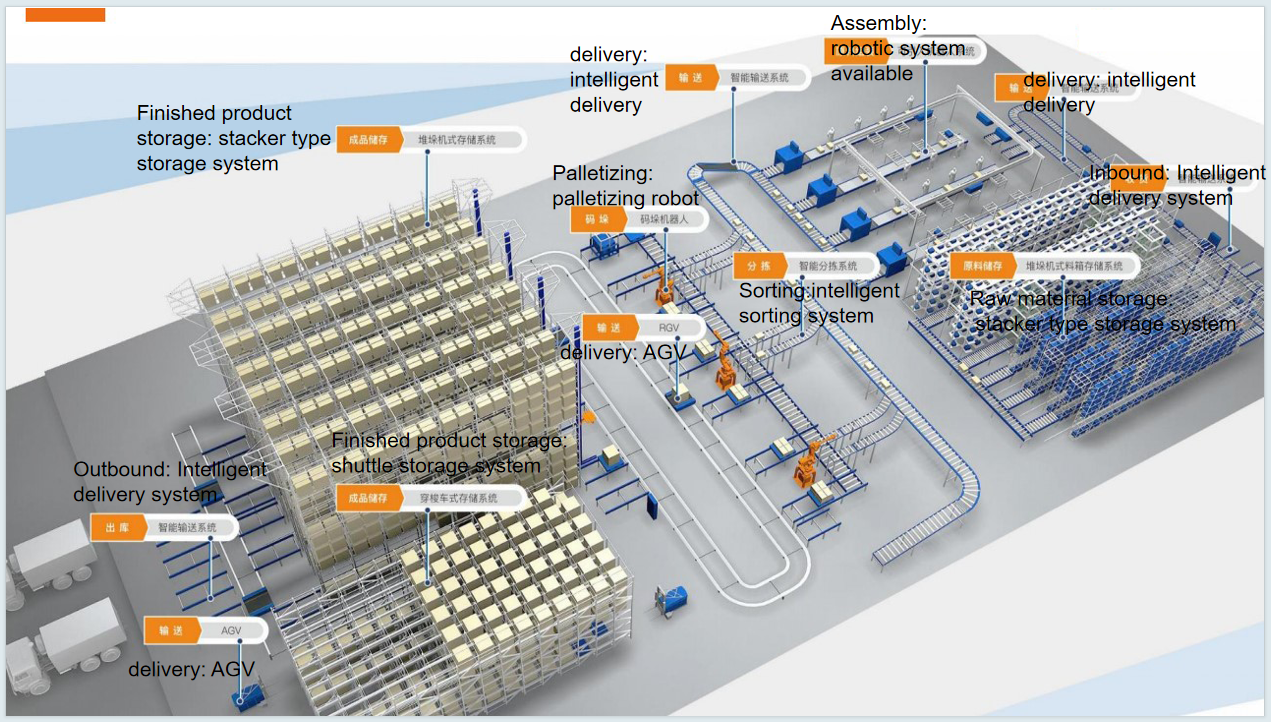

Intelligent logistics application scenarios

Core product introduction

Equipment configuration- -the four-way vehicle shelf system

| Rated load | running speed | electric energy | cell | Battery charging time | Battery life | ambient temperature | Equipment self-respect |

| 1.0 T | 1.5m/s | 48V/40AH | lithium iron phosphate | ≤1.5h | 6~8 Hours | 0~45℃ | 450kg |

Four directions

Drive along the longitudinal or transverse track and reach the planeAny cargo position

Change track in situ

Change the track on the cross track, there is no need for turning space

Intelligent control

The terminal is free scheduling to realize automatic unattended

Dynamic management

Multi-vehicle scheduling automatically avoids

Automated material handling solution with the best efficiency and resource ratio, the practitioner of unmanned warehouse.

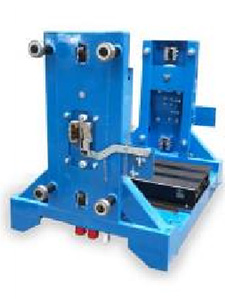

Equipment configuration- -a four-way shuttle car

A variety of sensors

Multiple sensors, self, main obstacle avoidance, perception tray is, no skew to ensure the positioning accuracy ± 2mm

A variety of sensors

Smoke temperature sensor, perception of warehouse fire point, real-time monitoring, danger immediate alarm

Touch the display

8-inch touch screen, In ter processor, 4G memory car body interior and server data double backup

5.8 GWIFI communication, change the communication mode to ensure smooth communication

Hydraulic jacking

Stronger load capacity without oil leakage and oil seepage

Road wheel

Glrap structure, vibration and noise reduction

The rim protrusions, autonomous guidance, guide high speed driving to prevent deviation

Temporary charging port

The side of the body is equipped with Anderson, charging plug, external power, source, maintenance and temporary charging

Anti-skid bracket

Contact surface pressing non-skid

Side bending to strengthen the bearing capacity

Backup battery replacement port

Built-in battery management system BMS; real-time feedback, automatic charging

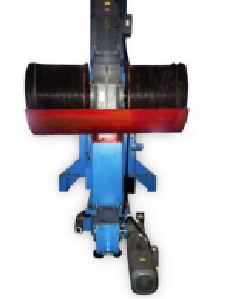

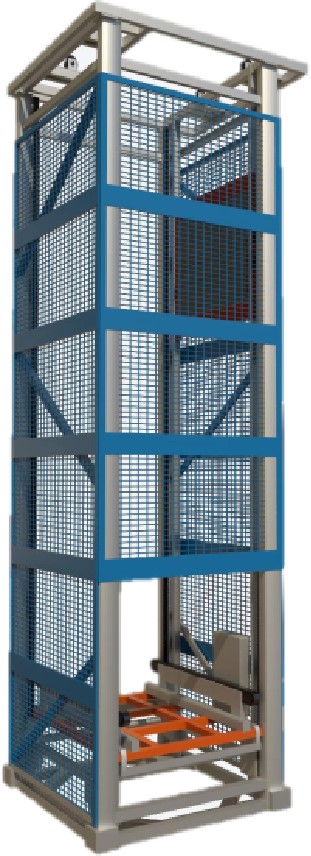

Core product: AS / RS stacker

Hoist rope

6 times the safety factor design, the choice of imported lubrication-free wire rope

Catcer

Abnormal lifting overspeed can effectively put the cargo platform clamp on the column guide rail

Stacker is a kind of automatic material handling equipment, as the core equipment of three-dimensional warehouse. The three-dimensional warehouse can improve the utilization rate of unit area, improve labor productivity, reduce labor intensity and production cost; reduce the errors of goods and information processing; manage and control the materials reasonably and effectively, meet the needs of special storage environment, improve the quality of operation, ensure the safety of goods in the whole storage process, and facilitate the overall optimization of the system.

1. Fast and efficient Stacker has fast operation speed, strong reliability and high accurate access rate

2. High safety profile -Stacker is designed according to the highest safety level in Europe -Key core components and controllers are adopted from high-end European brands

3. High hardware configuration -Up to 32 meters high, working in different environments, including-30 degree cold storage -Frequency frequency motor, the fastest speed up to 240M / M, higher composite operation capacity

4. Energy consumption and energy resources can be recycled -Minimize the number of parts -Long machine life -Low operation and maintenance costs

Equipment configuration

| Rated load | running speed | Run the acceleration | positioning accuracy | Lift structure | Carrying equipment |

| 1.5 T | 0.6~0.9m/s | 0.3m/s2 | ±1mm | Gear teeth | Car / cargo / vehicle and cargo |

Advantages over the traditional elevator

- Increase the running speed- - - - - -0.9 m/s

- Improve the positioning accuracy- - ± 1mm

- Docking form- - - - - - - - - - - - - - -3 kinds

- Reduce the carrier subsidence within -3mm

Equipment configuration- -four-way vehicle transport, machine delivery system

Pictures are for reference only, mainly with a detailed design

1 | transporting velocity | 12m / min (subject to the actual design) |

2 | Body material | Carbon steel spray plastic |

3 | Drive way | motor drive |

4 | Motor brand | SEW |

5 | Rated bearing | 1000KG |

6 | driving mode | chain |

7 | control method | Manual / single-machine automatic / online automatic |

1 | transporting velocity | 12m / min (subject to the actual design) |

2 | Body material | Carbon steel spray plastic |

3 | Drive way | motor drive |

4 | Motor brand | SEW |

5 | Rated bearing | 1000KG |

6 | driving mode | chain |

7 | The drum form | Steel double sprocket galvanized roller |

Core product: Delivery system

The intelligent conveying system can be associated with the three-dimensional library, including various kinds of conveyors, automatic guide vehicle (AGV), rail shuttle vehicle (RGV), etc., to realize the straight line, curve, lift and other transportation of the storage unit. We can design different transportation schemes according to the access mode of the stereo library.

We integrated delivery system, highly flexible for easy assembly and maintenance. In order to reduce the failure rate, our equipment pursues simplification from the structure, and reduces the requirements for operators in the operation. By working with upstream high-quality suppliers, we integrates reliable and durable mechanical equipment, applied in different internal logistics fields, such as pallet conveying system, material box conveying system,

Belt conveyor

Features: reliable operation, low power consumption, strong adaptability and flexible transmission line. Application: mainly used in the material transport line of the fixed destination

Track Shuttle Vehicle (RGV

Features: in the logistics system is widely used, fast speed, high reliability, low cost Applicable: mainly used in the automatic logistics system unit material high-speed, efficient plane automatic transmission

Roller conveyor

Features: simple structure, high reliability, easy to use and maintain. The capacity is large, fast speed, light operation, can realize multiple variety collinear shunt transmission. Applicable:, all kinds of boxes, bags, trays and other pieces of transportation, bulk materials, small items or irregular items should be placed on the tray or turnover box transportation. Trlets can be handled by a forklift.

Automatic guide car

Features: high work efficiency, high station identification ability and positioning accuracy, can achieve flexible logistics control; flexible and suitable for a variety of scenarios, high reliability. Applicable: Flexible for raw material transportation, pallet transportation, process assembly, finished product transportation, special scene transportation and other work scenarios

Chain conveyor

Features: chain conveyor transport capacity, conveying chain structure forms are diverse, and has a variety of accessories, easy to achieve the delivery. Applicable: can be used as assembly line or as material storage transport, transport tray, large turnover box, etc.

Core product: LIFT AGV

Several mainstream AGV navigation mode comparison

| Several mainstream AGV navigation mode comparison | |||||

| Magnetic strip navigation | QR code navigation | Laser navigation (with reverse) | Laser Navigation (SLAM) | Visual navigation (VSLAM) | |

| usage scenario | Workshop internal logistics | E-commerce unmanned environment | indoor environment | The indoor environment is relatively fixed | indoor environment |

| object of reference | magnetic stripe +RFID | two-dimension code | reflector panel | No need to layout, take the surrounding environment as a reference | No tracks and landmarks are required |

| positioning accuracy | ±10mm | ±10mm | ±15mm | ±15mm | ±15mm |

| Regular speed | 0-40m/min | 0-90m/min | 0-72m/min | 0-72m/min | 0-72m/min |

| superiority | AGV positioning is accurate, and it is easy to lay, change or expand paths compared with electromagnetic navigation. The netic stripe cost is low. In the human-computer interaction environment, the use of laser obstacle avoidance, can be better to avoid | AGV positioning is accurate, small and flexible, and easy to lay and change the path. Easy to control communication, no interference to sound and light. The overall scheduling traffic control is more flexible, can be in the direction of four two-dimensional code, to avoid, and route modification. | The AGV is positioned accurately; no other positioning facilities are required on the ground. The driving path can be flexible, changeable, and can be suitable for a variety of field environments. It is the advanced navigation method first adopted by the manufacturers of many AGVs at home and abroad. | No additional equipment is required to decorate the environment, and the route is easily extended. Scheduling and avoidance is more flexible. | Precise positioning, ground without other positioning facilities, suitable for all kinds of production working environment. Autonomous positioning, independent decision-making, automatic path planning and flexible obstacle avoidance. |

Core product: LIFT AGV

| Model number: BM12 | ||

| maximum load | 1200kg | |

| cabinet minister | 1740mm | |

| total width | 1505mm | |

| turning radius | omnidirectional | |

| Navigation mode | Magnetic strip guide | |

| positioning accuracy | ± 5mm (secondary positioning) | |

| noncontacting proximity sensor | The SICK security protection lidar | |

| touch sensor | conductive rubber | |

| Sound and light warning template | Sound, light prompt | |

| wireless network | technical grade WIFI | |

| system interface | Reserve the MES and scheduling system interfaces | |

| Minimum height of cargo fork | 50mm | |

| Driving speed of m / min | ≤120m/min | |

| Walking way | Forward, back, and turn | |

| climbing capacity | ≤8% | |

| Battery type | Lithium-battery / lead-acid batteries | |

| battery capacity | 150/280AH | 150/320AH |

| Charging method | Online autonomous charging / manual charging | |

Arabic

Arabic Bulgarian

Bulgarian Czech

Czech Danish

Danish Dutch

Dutch English

English Estonian

Estonian Finnish

Finnish French

French Georgian

Georgian German

German Greek

Greek Hungarian

Hungarian Icelandic

Icelandic Irish

Irish Italian

Italian Japanese

Japanese Korean

Korean Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Myanmar (Burmese)

Myanmar (Burmese) Norwegian

Norwegian Persian

Persian Polish

Polish Portuguese

Portuguese Romanian

Romanian Russian

Russian Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese