Source: Pinterest

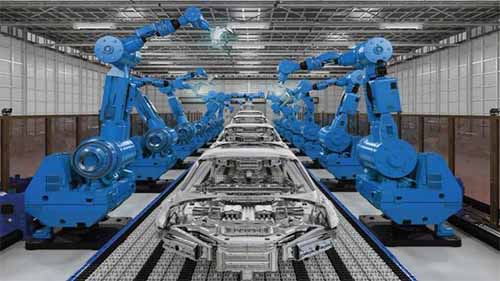

In the modern world, industrial robots are playing an essential part, especially in the manufacturing process. There are various advantages of employing industrial robots in factories. From accelerating the manufacturing process to providing a systematic production, industrial robots have taken over the capital market.

Robotic Process Automation is a process through which an industrial robot can be automated to emulate human actions. Industrial robots are programmed to carry out the tasks through the process of RPA. These robots perform the actions with the help of a robot arm known as a factory robot arm. A factory robot arm is similar in function to a human arm. It can have a variety of functionalities depending on the orientation of the robot. The varieties available include high-speed robot arm, waterproof robotic arm, big robot arm, tabletop robot arm, automatic robot arm, mechanical or pneumatic robot arm.

Following are the advantages of shifting towards automated robots in industries:

Greater Work Efficiency

Source: Pinterest

Unlike humans, robots do not get tired. Automated robot systems do not need breaks between the work. They can be left to work all day. As a result, industrial robots yield more productivity than manual labor does. Automated robots also lead to reduced factory hours as they can complete the tasks quickly and efficiently when compared to human labor.

Earlier, robots could be programmed to carry out only a few tasks. Over the course of decades, robots have emerged to be smarter and more efficient. With the emergence of Artificial Intelligence and the integration of numerous sensors, different types of industrial robots have been developed. These industrial robots can imitate the highest level of craftsmanship and as a result, are a hundredfold better than manual labor.

Consistent Productivity

Source: Pinterest

Manual labor cannot provide the same level of consistency and repeatability as an automated robot does. Industrial robots can perform the same task over and over again with the same amount of efficiency. Automated robots ensure error-free work because of their ability to perform a task multiple times. High-speed robot arms are the most efficient in this domain and can provide better consistency.

Reduced Floor Space

Source: Google

Employing a large labor force means making space for each individual and the team as a whole. Human labor also needs added space by way of restrooms, common areas, cafeterias, and more. Leveraging human force in confined working environments can sometimes cause fatal injuries.

On the other hand, replacing human labor with robots can save a lot of floor space. For one, with the advancement in technology, robots are shrinking in size. Industrial automated robots also require fewer tools, machinery, and materials. They optimize the process and produce less waste. Industrial automated robots can be confined to one place with the help of safeguarding fences. Also, a single robot can take over the work of a number of different people. All these factors translate to reduced floor space.

Using robots with big robotic arms can also save a lot of space.

Better Health Safety

Source: Pinterest

Manufacturing companies and factories emit different waste products such as fumes and poisonous gases. Employing manual or human labor in such areas can be extremely hazardous to human health. This is where automated industrial robots come in. Industrial robots will perform the tasks quickly and will also save the potential harm to the human body by taking over the manufacturing process.

Error-Less Multitasking

Source: Pinterest

Industrial Robot Companies from around the globe are preferring automated robots over human labor. This is because industrial robots provide an error-free process that ensures high accuracy. Robots are also known for performing a variety of tasks at one time which is humanly impossible.

More Growth Opportunities

Unlike humans, robots do not get fatigued and because of this consistency, growth is accelerated. With modern manufacturing processes, some tasks cannot be performed manually. Automation is required to carry out such tasks efficiently and once it is sought, productivity levels sky-rocket.

Source: Pinterest

Easier Customization

Manufacturing robot companies are now capable of creating customized robotics according to their client’s specific needs. In industries, there are many complicated tasks and it can be impractical or sometimes even impossible to train manual labor for each vastly different specialized task.

Unlike human laborers, a robot can be trained to do practically anything. If the required task has various complicated steps, a fully automated system can be customized and programmed to perform all of them efficiently.

Exceeding Human Abilities

Source: Pinterest

There are some tasks that humans cannot do, no matter how hard they try. For example, in a car factory, no human can possibly pick up the car frame to paint it from all sides. But robot arms and spray paint mechanisms can do that easily.

Explosive Ordnance Robots are used for scanning suspicious objects for explosives and defusing the bomb if found. This task, if done manually, is extremely dangerous for the person performing it.

Conclusion

There is no doubt that robots are dominating the world’s factories and industries. Whether it is about employing robotics in the food industry or in automobile industries such as car manufacturing robots, robots have completely taken over the market.

Different types of manufacturing robots are being introduced by industrial robot companies. The progress in the field of automation and robotics has been growing and seems to be evolving in the upcoming years. Take advantage of this emerging trend and automate your business today.