Source: www.idtechex.com

The use of robotic arms in the manufacturing industry is on the rise with more businesses getting on to the benefits of using robotic arms. If you plan to incorporate robotic arms into your business processes, then you need to ensure that you are well informed. Look for a quality robotic arm manufacturer that you can work with for quality results.

The robotic arm features the body, wrist, and also end effector. The end effector is what is used to hold on to different products or take on various tasks. In most cases, you’ll need the end effector to move in different directions with precision. This is where you need to ensure that you are aware of robot singularity and how it affects the performance of your robotic arm. In this article, we go in-depth into the robot singularity and why it is essential to keep it in mind.

What is Robot Singularity

Source: www.technologyreview.com

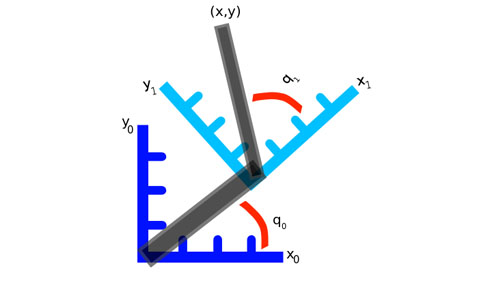

Robot singularity refers to a configuration where the robot end effector’s movement is blocked in certain directions. This configuration results in a limit to the efficiency and precision of the robotic arm you are working with. Generally, when it comes to 6-axis robotic arms, they work by moving in motions relative to X, Y, and Z axes in a 3D or Cartesian plane. It consists of 6 joints that contribute to the 6 degrees of freedom experienced by the robotic arm while in action.

This degree of freedom allows the robotic arm to move in different directions and easily get to achieve the tasks it is designed for. If by any chance, the robot end-effector is not able to get to the products or moves in the wrong direction, this is where the singularity issue comes in. Some singularities are quite easy to identify and solve allowing you to head back to your tasks. However, on the other hand, some robots will experience singularities harder to identify unless with the help of complex and lengthy formulas.

What Affects Robot Singularity?

Source: www.mecademic.com

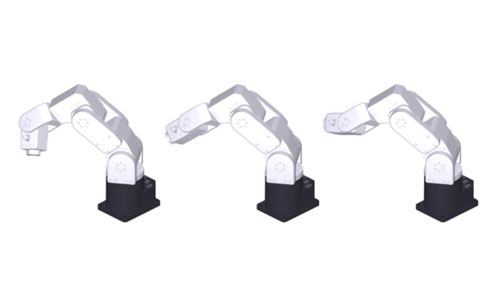

Robot singularity will feature different effects and also challenges especially when identifying the specific problems. These challenges vary depending on a few factors featured on the robotic arm you’ll be working with. The complexity and severity of the singularity experienced by your robot are dependent on the number of joints, type of robot ( linear or rotary ), and the geometric arrangement.

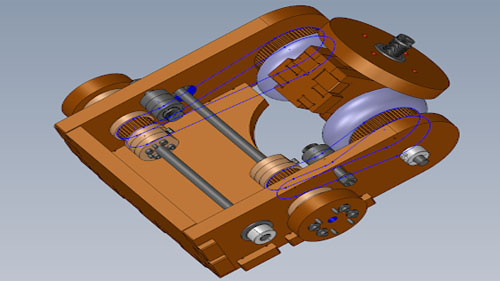

An industrial robot arm features two spaces where it can easily be controlled. This is usually the joint space and the cartesian space. With the different spaces where the robotic arm operates, you find that it will feature two sets of position-mode motion commands.

When it comes to the joint space commands, the robot will receive specific instructions with the desired set of joint spaces. It will then move to bring each joint to the suggested joint positioning in a linear and simultaneous translation. With the cartesian space commands, the suggestion to the robot will feature the desired pose for the end effector with a specific cartesian path. The cartesian path is designed to either be linear or circular.

For the robot to align accurately with the cartesian joint and commands, the robot controller calculates the inverse position and velocity kinematics of the robot. This results in the right positioning of the end effector to carry out the designed task. However, if the calculations are wrong then the singularities occur where you find the end effector is not accurately positioned. This shows you the configurations you want to avoid to prevent the singularity problems from hindering your automation processes.

Functions of Robot Singularity

Source: www.dignited.com

Granted robot singularities should be avoided at all costs to ensure that your industrial robotic arm can work at its best on the desired tasks. Learning more about the function of the robot singularity will give you a better understanding of why you should aim to avoid it. Robot singularity is mainly associated with two distinct functions.

The Decline in Velocity Mapping

Source: studywolf.wordpress.com

Consider two cartesian robots used to orient their end effectors to different directions. The two robots feature the six-axis positioning with stacks of three orthogonal linear guides and three rotation stages. When the robot used can keep the axes and joints where they are meant to be, then the orientation of the end effector is easy.

It can continuously use the end-effector along the 6D path within its workspace while maintaining precision and accuracy. However, when the axes and the joints coincide, a singularity occurs and the robot is no longer able to move with the 6 degrees of freedom at its disposal.

With this robot, you find that it cannot rotate its end effector about the axes that coincide with the revolute joints. This kind of singularity is often referred to as the gimbal lock. Given that most singularities are solved with the help of equations you find that it becomes harder to determine the velocity of certain cartesian vectors. When the singularity occurs it hinders the capability for you to figure out the intensity in numbers associated with the velocities being featured.

Being able to measure the velocities of a robotic arm is essential to ensure that you observe safety. When facing a singularity problem you find that it poses a great risk on robotics even though they are not at that point yet. It results in high joint velocities that may be dangerous especially if you are working with big and fast industrial robots. This is why mapping out the velocities you are working with is so important.

Limited Internal Workspace Boundaries

Source: Youtube

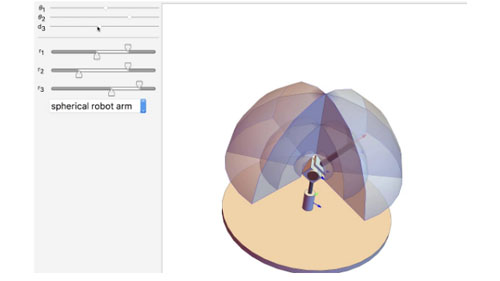

When it comes to robot singularity it not only affects the inverse velocity kinematics but also trickles down to the inverse position kinematic equations. When working with industrial robots you’ll find that they feature equations and solutions for different joint positions. The different solutions featured are closely linked to the different configuration types.

For instance, if your robot features 8 unique solutions for joint positions to the end effector position, it will also feature 8 different configuration types. To change a configuration type you would have to go through a singularity. Singularities are the boundaries found in between the 6D entities featured in the cartesian workspace is a typical 6 axis robot. This limits the different configurations you can achieve and the workspace boundaries available to your industrial robot.

Types of Robot Singularity in a Vertically-articulated Robot

Source: blog.grabcad.com

Given the fact that robot singularities may occur in any industrial robotic arm you are working with, it is important to realize that there are different types. Just like the robotic arm comes in different parts, the singularities will also affect these different parts resulting in a variety of problems.

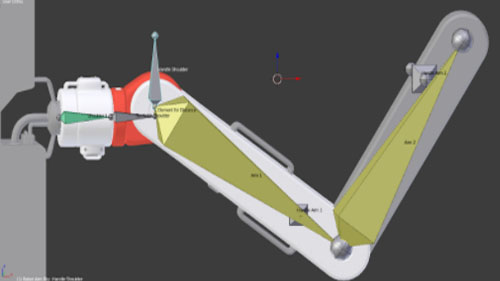

Here, it is important to keep in mind the different axes of joints featured in industrial robotic arms. You’ll be working with 2 and 3 that are parallel, 1 and 4 that are normal to 2 and 3, the axis of joint 5 that is normal to the axes joints of 4 and 6. Now that you have a better understanding of the different axes and joints you are in a better place to explore the singularity types. The most apparent types of singularities in a vertically articulated robot arm to consider include:

Wrist Singularity

Source: sites.google.com

When it comes to vertically articulated robot arms with inline wrists, they tend to have wrist singularity as the most prevalent issue. This type of singularity occurs when the axes of joints 4 and 6 coincide with each other. When this happens, the wrist is not able to move the end effector in the direction of the axis of joint 5. In application, consider an industrial robot arm that is working accurately.

For it to follow a line through the singularity, the joints 4 and 6 have to be simultaneous and rotate at 90 degrees. This will be done in opposite directions to ensure that the process is accurate. This goes to show that crossing a wrist singularity is feasible. However, once you get to the singularity, the end effector remains motionless while the two joints rotate. For the end effector to cross the singularity, it has to stop first. If it was in application, it would hinder the accuracy of the industrial arm while at work. There are tons of solutions for wrist singularity that can easily be implemented to correct the problem.

Elbow Singularity

Source: www.electronicsteacher.com

The second type of singularity that you may come across when working with vertically articulated robot arms with inline wrists is elbow singularity. It mainly occurs when the wrist center lies on the plane passing through the axes of joints 2 and 3. The wrist center is used to refer to the point where the axes of joints 4, 5, and 6 intersect. In the elbow singularity, you’ll find that the arm is fully stretched and may also feature some instances where it cannot be fully folded. This kind of singularity is mostly determined by the axis and position of joint 3. The elbow singularity also features a couple of solutions that can help you solve any performance issues you may be experiencing with your robotic arm. This type of singularity occurs quite often and can easily be predicted and also avoided.

Shoulder Singularity

Source: blenderartists.org

The final singularity that you may encounter is the shoulder singularity that occurs when the center of the robot wrist lies on the line passing through the axes of joints 1 and 2. This singularity is the most complex among the rest given that it does not depend on a single joint position. With the shoulder singularity, the limitation is placed on the movement in the direction of the axis of joint 2.

In application, for the robot to follow a line through the shoulder singularity, joints 1 and 4 have to be rotating simultaneously at a 90-degree angle. This rotation like in the wrist singularity is done in opposite directions while the end effector remains constant. Like in the wrist singularity, the movement through the shoulder singularity is possible however, the end effector will have to stop to make that possible. This singularity also features a few solutions that can be implemented to ensure that the robotic arm is back to working at its best.

Types of Singularity in a Six-axis Collaborative Robot (Cobot)

Source: www.istockphoto.com

When it comes to collaborative robots, you’ll find the axes of joints 2, 3, and 4 which are parallel, the axis of joint 1 intersects and is normal to the axes of joint 2. Additionally, it also features the axis of joint 5 that intersects and is normal to the axes of joints 4 and 6. Like the singularities in the articulated robots, these robots also feature different solutions relative to the different configuration types. The types of singularities included in Cobots include:

Wrist Singularity

The wrist singularity in these robots occurs when the axes of joints 4 and 6 become parallel. In this situation, you may find that the axes of joints 2, 3, 4, and 5 can move while the end effector remains constant.

Elbow Singularity

In these robots, the elbow singularity occurs when the axes of joints 2, 3, and 4 are in the same plane. This greatly limits the movement of the end effector and in turn, affects the performance of the robotic arm.

Shoulder Singularity

The shoulder singularity occurs when the intersection point of the axes of joints 5 and 6 lie in the plane passing through axes of joints 1 and 2. Here there are a few solutions that can be implemented to remedy the singularity and have a working industrial robot.

How to Avoid Singularity in Robotics

Source: www.ennomotive.com

With the different effects, robot singularity has on the manufacturing processes, having ways to avoid them is essential. Given that different types of robots, singularities vary depending on the kind of robot you are working with, having a basic understanding of how to avoid them will ensure that your processes run with ease. Generally, singularities can only be avoided by ensuring that your robotic cells are properly designed. This also trickles down to the design featured on the adaptor plate you choose to use for your end effector.

For instance, if you happen to configure your robotic arm and poorly assign a pick location to correspond with a wrist singularity, then there’s not much you can do to solve the problem. With this, the only thing to do is check if the pose can be used in a nonsingular application. Additionally, singularities can also be avoided by adding small angles to the tooling. This goes a long way to help reduce the chances that the robot will move into a singularity. This is a technique that is mainly used by technicians who understand the mechanics and can tweak the solutions to their advantage.

Lastly, the singularities can also be avoided by taking the programming approach and have mathematics help you take care of things. In this, you’ll find that the number of axes is greatly reduced to make it possible to avoid the singularity. This mainly because a higher number of axes increases the chances of singularities occurring. Remember, singularities occur when axes align with each other blocking the movement of the robotic arms in certain directions. Reducing the number of axes also decreases the chances of them aligning and causing any blockages.

Conclusion

Robot singularity is a great problem that is experienced in different industrial applications of robotic arms and other automation equipment. Dealing with these problems by yourself can prove to be a drag which is why you should try to avoid the robot singularity. However, if you encounter this problem, you can find a solution or hire a savvy technician who will cater to the problem.

Alternatively, build a close working relationship with a reputable automation equipment manufacturer who will help you when you encounter any singularities. Take your time to ensure that your robotic equipment works well to help you fully customize and capitalize on its use for your business.