The combination of laser welding robots and assembly robots is crucial in today’s production environment to improve precision and streamline processes. These robots provide unmatched precision, increase safety, and maximize efficiency. While assembly robots automate routine activities like component placement and fastening, laser welding robots are made to tackle complex welding jobs. The cutting-edge technology underlying laser welding robots and assembly robots is demonstrated by the EVS robotic models QJR20-1600, QJR10-2, and QJR210-1. These robotic arms improve performance in a variety of applications by combining strong payload capabilities with the adaptability of six-axis mobility.

The Advantages of Robots with Laser Welding in Contemporary Manufacturing

Because they provide exact control over heat input and welding routes, laser welding robots greatly improve the quality of the weld. For example, the QJR20-1600 robotic arm is perfect for medium to big welding activities since it can reach up to 1671mm and hold up to 20kg of cargo. Because laser welding robots are so precise, less mistakes are made and manufacturing lines produce consistent output. These robots work especially well in sectors like aerospace and automotive, where even little welding mistakes can result in serious flaws. Complex welding activities may be automated using laser welding robots, which decreases the requirement for human labor with expertise and expedites output.

Accuracy and Adaptability of Assembly Line Robots

In sectors where repetitive and delicate assembly activities are required, assembly robots are indispensable. By automating processes like part location, insertion, and fastening, these robots boost efficiency. Having a reach of 2001 mm and a payload of 10 kg, the QJR10-2 is an excellent illustration of an assembly robot made for high-precision work. Because of its six-axis flexibility, it can easily assemble complex components in tight places. Automation of the assembly process lowers human error and boosts productivity, which is why assembly robots are essential in sectors like consumer products and electronics.

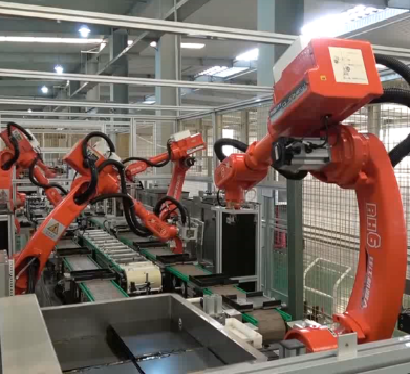

How Efficiency Is Increased by Combining Assembly and Laser welding robots

When assembly robots and laser welding robots work together on the same manufacturing line, their full potential is realized. While assembly robots work effectively to build components, laser welding robots perform precision welding duties. This combination minimizes downtime and manual intervention by ensuring seamless transitions between the welding and assembly processes. With a 2688mm reach and a 210kg payload, the QJR210-1 can handle heavy-duty welding and assembly work. Because of its six axes of motion, it may be applied in a variety of industrial operations. Manufacturers may increase production and reduce operating costs by streamlining processes using this robot in addition to laser welding robots.

Cutting Expenses and Raising Security

By reducing the requirement for specialized manpower, the integration of laser welding robots and assembly robots into industrial processes results in a considerable reduction of operating expenses. Robots that use laser welding technology are able to produce continuously because they can precisely weld without becoming tired. Similar to this, assembly robots improve output consistency and save labor costs by doing repeated assembly jobs without the need for human involvement. Another significant advantage of these robots is safety. Laser welding robots lower the likelihood of workplace accidents by automating risky jobs. Furthermore, assembly robots reduce the risk of harm in jobs that require repetitive motion or high ergonomic demands. This guarantees efficient functioning and creates a safer work environment.

Superior Characteristics of EVS Robotic Models

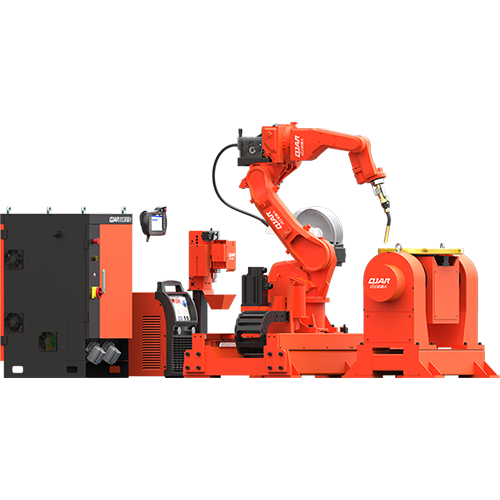

EVS offers three models that showcase the advanced capabilities of laser welding robots and assembly robots: QJR20-1600, QJR10-2, and QJR210-1. With its six-axis motion, 20kg payload, and 1671mm reach, the QJR20-1600 is the perfect tool for high-speed welding applications involving medium-to-large components. Because of its accuracy, welding errors are reduced, improving the overall quality of the output.

With its 10kg payload and 2001mm reach, the QJR10-2 offers remarkable versatility for challenging assembly jobs. This assembly robot is perfect for sectors like electronics and medical equipment since it is made for sensitive operations in confined places.

With a 2688mm reach and a 210kg payload for large-scale operations, the QJR210-1 is a reliable option for welding and assembly jobs in harsh industrial settings. It is a flexible asset in modern production because of its six-axis adaptability, which allows it to adapt to a variety of jobs.

Assembly and Laser welding robots: The Future of Manufacturing

Laser welding robots and assembly robots will become more and more crucial as automation technology develops. With improved real-time adjustment and adaptive control capabilities, these robots are becoming increasingly intelligent. More advanced sensors and machine learning will probably be included into laser welding robots, enabling them to make changes for even greater precision as they weld.

Similarly, enhanced vision systems and AI-driven control will let assembly robots do increasingly complicated assembly jobs more effectively. For manufacturers, this will mean more chances to streamline their operations, cut expenses, and raise the caliber of their output.

In summary

In conclusion, laser welding robots and assembly robots, which offer unparalleled accuracy, speed, and efficiency, are essential parts of contemporary industry. Robotic models from EVS, such as the QJR20-1600, QJR10-2, and QJR210-1, demonstrate the effectiveness of automation in managing activities related to welding and assembly. Manufacturers may save operating costs, increase productivity, and guarantee consistent product quality by combining laser welding robots with assembly robots. In the future, industrial automation will rely even more on these robots, which will help businesses remain competitive in a market that is changing quickly.